QT9-20 Concrete Block Making Machine

| Concrete Block Making Machine | Four-direction positioning for Material Distribution | Air Bag | Pallet Centering |

The QT9-20 concrete block making machine can make various concrete products with the height range of 50 to 200mm. You can use it to make color floor tile, hollow block, and so on. This machine operates stably and has high productivity. The forming cycle is short. The concrete block maker is suitable for the clients who require high output and high degree of automation.

Advantages

| 1. Translational Distribution Method | |||

| The QT9-20 concrete block making machine applies the double hyperbolic arm for materials distribution. This translational distribution method can shorten the distributing time by 30% to 50%. | |||

| 2. Air-bag Clamping Method | |||

| The air-bag clamping method is used to maximize the exciting force while reducing the system pressure. | |||

| 3. Double Valve Controlled Hydraulic System | |||

| The hydraulic system is controlled by the double valve, which can be adjusted according to the hydraulic flow and pressure. | |||

| 4. Electrically Controlled Aggregate Hopper | |||

| The aggregate hopper can be electrically opened for discharging. The discharging is adjustable according to different block types. | |||

| 5. Frequency Transformer Controlled Vibrating System | |||

| The vibrating system is controlled by the frequency transformer, so the equipment operates more stably. | |||

| 6. Double Cylinders, Ash Scraping Device, and Centering Device | |||

| Controlled by the double cylinders, the hopper allows for fast and uniform materials distribution. The cylinders are stable in operation, and have no scratch or collision. In addition, a second ash scraping device has been equipped for preventing the excess materials from affecting the finished products. On the bottom of the equipment, there is a centering device used to avoid the plate drifting. | |||

| 7. Cleaning Device | |||

| A cleaning device is installed in front of the block making machine, so as to make sure the beautiful appearance of the concrete product. | |||

Except the above seven advantages, The QT9-20 concrete block making machine share the same advantages with the QT5-20A3.

Parameters

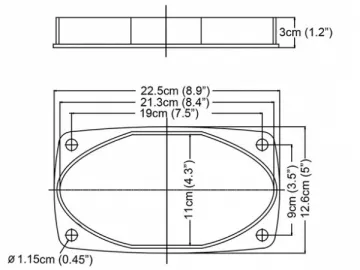

| Support Plate Size | 1350*750*30mm |

| Forming Cycle | 20~25 seconds per time (Different product has different forming time)(Surface materials is excluded) |

| Product Height | 50~200mm |

| Operating System | Full Automatic |

| Total Installed Capacity | 40.25Kw |

| Overall Dimensions | 10, 790*2, 510*3, 370mm |

| Weight | 13,500kg |

| Maxi. Pressure | 10MPa |

| Molding Method | Vibration and pressure |

| Output | 200m3 (Mini. Output per 10 hours) 390*190*190mm |

| Executive Standard Number | JC/920-2011 Architecture material industry block machine |

Standard Configuration

Primary machine unit, pump station, surface material drawer, dust hopper with silo, pallet feeder, Bricks conveyer, conveyor, tool box, accessories, 20 pieces of 1, 350*750*30mm bamboo plywood, operation instruction, warranty card, product delivery form, palletizing machine

Remark

Raw Materials: Construction waste, coal ash, river sand, cement, stones, and slag

Finished Product

| H-shaped Concrete Bloc | Interlocking Treepit Block |

Related Names

Cement Brick Machine | Shaped Brick Equipment | Interlocking Block Machine

Links:https://globefindpro.com/products/85559.html

-

QT4-20B2 Concrete Block Making Machine

QT4-20B2 Concrete Block Making Machine

-

QT10-15 Concrete Block Making Machine

QT10-15 Concrete Block Making Machine

-

QT5-35Z Concrete Block Making Machine

QT5-35Z Concrete Block Making Machine

-

BTS Mini Series

BTS Mini Series

-

QM5-18 Concrete Block Making Machine

QM5-18 Concrete Block Making Machine

-

ACS Series

ACS Series

-

QT6-20B1 Concrete Block Making Machine

QT6-20B1 Concrete Block Making Machine

-

QWT21 I Type Concrete Block Production Line

QWT21 I Type Concrete Block Production Line

-

ATS Series

ATS Series

-

Diaphragm Suction Pool Cleaner

Diaphragm Suction Pool Cleaner

-

Aluminum Outdoor Solar Shower

Aluminum Outdoor Solar Shower

-

Mould of Concrete Block Molding Machine

Mould of Concrete Block Molding Machine