QT5-35Z Concrete Block Making Machine

The QT5-35Z concrete block making machine is a multifunctional, color hydraulic machine specially designed for producing thermal insulation composite blocks.

Product Instruction

1. The PLC controlled equipment is driven by hydraulic system, and monitored by the contactless proximity switch. It well combines the motor, electricity, hydraulic pressure, and high-frequency vibration.

2. By using imported ones or domestic well-known brands electric, hydraulic components, this machine is characterized by reliable performance, easy operation, low failure rate, and convenient maintenance.

Parameters

| Productivity per Time | 3 pieces of 390*310*190 self heat preservation blocks |

| Annual Output (two shifts per day, 8 hours per shift) | Self heat preservation block: 40,000 m3 |

| Product Height | 40~200mm |

| System Pressure | 10Mpa |

| Pallet Size | 1150*580* (25~40) mm |

| Pallet Capacity | 7 pieces |

| Cycle Period | 20~35 seconds per time (Different product has different forming time) |

| Total Installed Capacity | 27.15KW |

| Overall Dimensions | 6, 420*2, 650*3, 370mm |

| Machine Weight | 7, 000Kg |

| Output | 3, 600 pieces per 10 hours/10 |

Standard Configuration

Primary machine unit, pump station, pallets feeder, bricks conveyor, conveyor, 20 pieces of bamboo plywood, 4 handcarts, one set of self heat preservation block mold, spare parts, tool box, operation instruction

Remark

Raw Materials: Cement, stones, sand, coal ash, construction waste, talc powder, polystyrene board

Output: 3,600 pieces per 10 hours

Finished Product

| Insulation Block | Insulation Block | Insulation Block |

Related Names

Insulated Block Maker | Block Press Machine | Masonry Block Machine

Links:https://globefindpro.com/products/85563.html

-

BTS Mini Series

BTS Mini Series

-

QM5-18 Concrete Block Making Machine

QM5-18 Concrete Block Making Machine

-

ACS Series

ACS Series

-

QT2-30 Concrete Block Making Machine

QT2-30 Concrete Block Making Machine

-

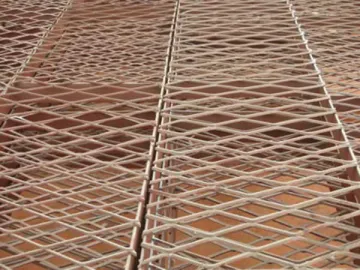

Steel Expanded Wire Mesh

Steel Expanded Wire Mesh

-

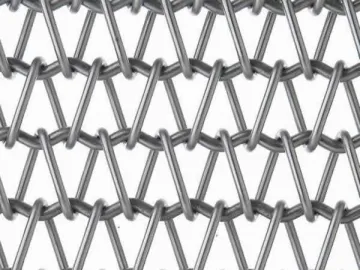

Chain Driven Wire Mesh Conveyor Belt

Chain Driven Wire Mesh Conveyor Belt

-

QT10-15 Concrete Block Making Machine

QT10-15 Concrete Block Making Machine

-

QT4-20B2 Concrete Block Making Machine

QT4-20B2 Concrete Block Making Machine

-

QT9-20 Concrete Block Making Machine

QT9-20 Concrete Block Making Machine

-

QT6-20B1 Concrete Block Making Machine

QT6-20B1 Concrete Block Making Machine

-

QWT21 I Type Concrete Block Production Line

QWT21 I Type Concrete Block Production Line

-

ATS Series

ATS Series