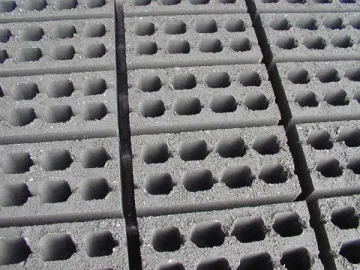

QT2-30 Concrete Block Making Machine

The QT2-30 concrete block making machine can make various kinds of concrete products, including color floor tile, lawn brick, kerb stones, etc. It offers a high return on a low investment.

Product Instruction

1. Our QT2-30 concrete block making machine is a jolt-squeeze molding machine. It is stable in operation, because of its integral type structure.

2. Each time, it can make several blocks, thus not only saving electric power and labor cost, but also allowing for the centralized transportation and stacking.

3. The automatic aggregate feeding system greatly lowers the labor intensity.

4. You can freely, conveniently, and quickly change the mould as you like.

5. Both pressing cylinder and mold stripping cylinder have the automatic balancing structure, so that the concrete product quality can be guaranteed.

Parameters

| Supporting Plate Size | 550*500* (8-20)mm |

| Concrete Product Height | 50-120mm |

| Area of Material Distribution | 520-420mm |

| Operating System | Semi-automatic |

| Installed Capacity (Total Power) | 6.2KW |

| Machine Weight | About 1t |

| Overall Dimensions | 3, 050*1, 250*2, 010mm |

| Forming Method | Vibration and pressure |

Standard Configuration

1. Main Frame: Primary machine unit, pump station, aggregate drawer

2. Supporting Plate: 20 pieces iron plate

Remark

Raw Materials: Construction waste, coal ash, river sand, cement, stone, slag

Finished Product

| Color Floor | H-shaped Concrete Block | Red S-shaped Concrete Block |

Related Names

Walkway Brick Maker | Fly Ash Brick Machine | Concrete Vibrating Machine

Links:https://globefindpro.com/products/85568.html

-

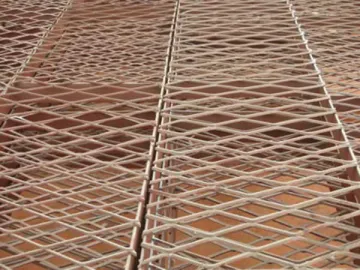

Steel Expanded Wire Mesh

Steel Expanded Wire Mesh

-

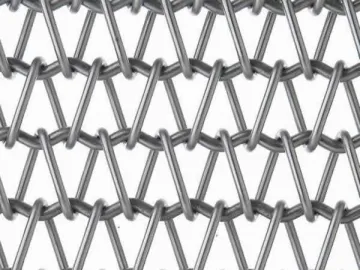

Chain Driven Wire Mesh Conveyor Belt

Chain Driven Wire Mesh Conveyor Belt

-

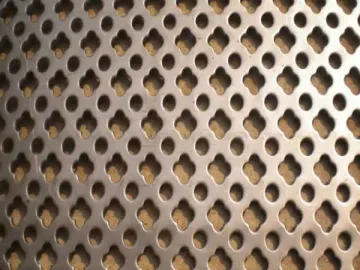

Perforated Metal Sheet

Perforated Metal Sheet

-

Plastic Mesh

Plastic Mesh

-

QWT12A4 Automatic Concrete Block Production Line

QWT12A4 Automatic Concrete Block Production Line

-

Swimming Pool Heat Pump Parts

Swimming Pool Heat Pump Parts

-

ACS Series

ACS Series

-

QM5-18 Concrete Block Making Machine

QM5-18 Concrete Block Making Machine

-

BTS Mini Series

BTS Mini Series

-

QT5-35Z Concrete Block Making Machine

QT5-35Z Concrete Block Making Machine

-

QT10-15 Concrete Block Making Machine

QT10-15 Concrete Block Making Machine

-

QT4-20B2 Concrete Block Making Machine

QT4-20B2 Concrete Block Making Machine