QWT12A4 Automatic Concrete Block Production Line

| 1. Descending Pallet Conveyor 2. Pallets Feeder 3. Primary Machine Unit 4. Bricks Conveeeyor 5. Palletizing Machine 6. Mixer 7. Batching Plant | 8. Conveyor 9. Cement Silo 10. Package Machine 11. Forklift 12. Loader 13. Control System |

Composition

The QWT12A4 automatic concrete block production line is comprised of batching and mixing system, molding system, delivery system, stack system, and control system.

Features

1. The production line applies the thick rectangular steel frame, four guide pillars, and king-size guide sleeves. In a word, the frame is durable in use.

2. Through the application of mandatory mechanical positioning, this production line can make concrete products with uniform height. Because of the encoder of the server motor, its two vibrators work synchronously.

4. We adopt a suspension type four-direction positioning aggregate trailer which has little resistance when operating. The trailer puts an end to the mold damage caused by the thickness error of the supporting plates.

5. QWT12A4 automatic concrete block production line is controlled by the international brand PLC program, thereby ensuring stable operation. Its operating parameters can be set and modified.

6. Its hydraulic system utilizes the imported hydraulic components. This integrated hydraulic station can automatically adjust the oil temperature. Therefore, the equipment can be continuously operated for a long time.

| Product | Output | QWT12A4 | Image |

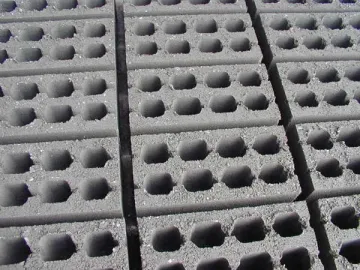

| Standard Hollow Block (390×190×190mm) | Qty. per Plate | 5 | |

| Annual Output | 5,510,000 | ||

| Pavement Tile (200×100×60mm) | Qty. per Plate | 25 | |

| Annual Output | 27,540,000 | ||

| Standard Block (240×115×53mm) | Qty. per Plate | 32 | |

| Annual Output | 35,250,000 |

Remark: The above data belongs to theoretical value, and the production efficiency should be calculated by 85%. Factors that will influence the actual output include product formula, raw materials, production equipment, etc.

Parameters of QWT12A4Block Making Machine

| Productivity | 5 pieces (standard blocks) per plate |

| Concrete Product Height | 50-200mm |

| Pallet Size | 1150×620×25mm(Bamboo Plywood) |

| Forming Cycle | 20-25 seconds per plate (It varies according to different products) |

| Total Power | 87.65KW |

| Overall Dimensions | 20787×12737×5312mm |

| Machine Weight | About 35, 472KG |

| Equipment Occupied Area | 273 m2 |

| Curing Area | 800 m2 |

| Storage Area for Concrete Products | 3, 000 m2 |

| Storage Area for Raw Materials | 600 m2 |

| Total Occupied Area | 4, 673 m2 |

Equipment List

| Equipment for QWT12A4 Automatic Concrete Block Production Line | ||||

| No. | Product Name | Code | Qty. | Remark |

| QWT12A4 Automatic Concrete Block Production Line | XSF-QWT12A4-00 | 1 | Straight Line | |

| Standard Configuration | ||||

| 1 | QT5-20A4 concrete block making machine | QT5-20A4-ZJ | 1 | Synchronous motor driven vibration system |

| 2 | Automatic Pump Station | QT5-20A4-ZJ-ZDBZ | 1 | |

| 3 | Electric Control Cabinet | QT5-20A4-ZJ-KZG | 1 | |

| 4 | Bricks Conveyor | XSF-CZJ2-00 | 1 | |

| 5 | Palletizing Machine | XSF-DBJ5-00 | 1 | Including electrohydraulic control system |

| 6 | Lowerator Delivery | XSF-JBS1-00 | 1 | Including lowerator, pallet delivery, electrohydraulic control system |

| 7 | Package Machine | XSF-MDXT-00 | 1 | See the remark |

| 8 | Pallets Feeder | XSF-SBJ6-0A | 1 | |

| 9 | 3.5m Conveyor | XSF-3.5SSJ-00 | 1 | Optional |

| 10 | Block Supporting Plate | 1150*620*25 | 20 | Bamboo Plywood |

| 11 | JS500 Mixer | 1 | Optional | |

| 12 | 1600III Batching Plant | XSF-PLJ1600III-00 | 1 | Optional |

| 13 | 100t Cement Silo | 1 | Optional | |

| 14 | Forklift | 2 | Purchased by the user | |

| 15 | Mold Loading or Unloading Trolley | XSF-QT5-MJZX-00 | 1 | Optional |

| Remark: The package machine is used when the pallet size is 1m *1m or 1.2m *1.2m. | ||||

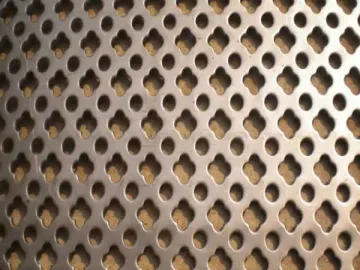

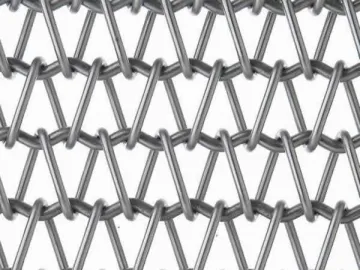

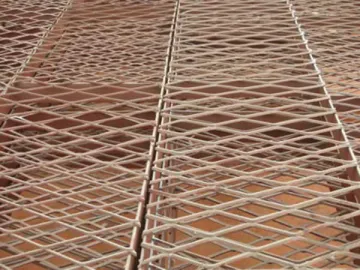

Finished Product

| Eight-hole Block | Interlocking Grass Block | Soil Retaining Block | Grass Block with Holes |

| Lawn Brick | Lawn Block with Round Holes | Grey Lawn Block with Round Holes |

Related Names

Lightweight Block Machine | Interlocking Brick Maker | Hollow Block Machinery

Links:https://globefindpro.com/products/85573.html