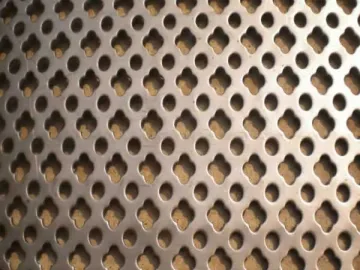

Perforated Metal Sheet

Perforated metal sheet refers to the plate in different materials with diversified holes, so as to satisfy various needs. It features high accuracy and good quality. Because of wide application, our product has different specifications, and can be customized according to your requirements. Packed in the kraft paper and wooden pallet, it will not be damaged in transit.

Application

1. Noise barrier along the railway, subway or expressway through the city

2. Acoustic panel in generator rooms, industrial buildings and other places demanding sound insulation and noise reduction

3. Decorative perforated plate of a table, chair, staircase or balcony

4. Protective cover of a machine and speaker grill

5. Food cover, fruit bowl, fruit basket and other kitchen ware

Material

Stainless steel sheet, galvanized sheet, low-carbon steel sheet, aluminium sheet, copper sheet and so on

Hole Pattern

Rectangular, square, rhombic, round, oblong, hex, cross, triangular hole, etc.

Manufacturing Process

1. Making Mould

Since the accuracy and quality of a mould greatly influences product quality, we have put a lot of money and energy into mould making, improved the ability to design and produce moulds, and accumulated some mould patterns.

2. Perforating

The galvanized perforated sheet is manufactured by the latest WKC-2000 CNC punching machine that is fed by a stepper motor and controlled by the PLC, which ensures the product precision of /-0.15mm. Furthermore, due to standardized management, the stamping range is 10mm--0.2mm.

3. Slitting Sheet

Cut the sheet into small pieces of sheet in appropriate size.

4. Shearing Sheet

Shear the sheet in accordance with your tolerance range.

5. Roller Leveling

The sheet flattening machine is able to level the transmutative product with the thickness of 0.8mm--12mm. The lubricant is used to clean punched holes, and oil removing process is added to remove oil and dirt. Several machining services are available to meet your needs.

6. Surface Treatment

Powder spraying, paint spraying, electrogalvanizing, hot galvanizing, anodizing and other additional surface treatment can be provided to prevent the imperfection of the product surface, if necessary.

General Parameters of Perforated Metal Sheet

| Material | Stainless steel, aluminium sheet, galvanized sheet |

| Thickness | 0.2--3mm |

| Width | 1000mm, 1250mm, 2000mm |

| Length | Plate: 1000--2000mm, coil: 1--30m |

| Hole pattern | Round, square, triangle, rhombic, hexagonal, scale |

| Plate edge | 10--20mm |

| Hole arrangement | Staggered, straight |

Specification of Perforated Metal Sheet

| Plates | Net thickness (mm) | Bore diameter (mm) | Center distance (mm) | Net width (m) | Net length (m) | Percentage of open area (%) | Weight (kg/m2) |

| Rolling plate | 0.2 | 6 | 2 | 1 | 20 | 44 | 0.88 |

| 0.35 | 5 | 4 | 1 | 20 | 24 | 2 | |

| 0.45 | 6 | 3 | 1 | 20 | 35 | 2.5 | |

| 0.8 | 3 | 3 | 1 | 20 | 19.6 | 3 | |

| Flat plate | 0.5 | 1 | 1 | 1 | 2 | 19.6 | 3.14 |

| 0.8 | 1.5 | 1.5 | 1 | 2 | 19.6 | 5 | |

| 1.5 | 2 | 2 | 1 | 2 | 19.6 | 9.4 | |

| 3 | 5 | 16 | 1 | 2 | 19.6 | 18.8 | |

| Stainless steel plate | 0.5 | 1 | 1 | 1 | 2 | 19.6 | 3.14 |

| 0.8 | 1.5 | 1.5 | 1 | 2 | 19.6 | 5 | |

| 1 | 2 | 2 | 1 | 2 | 19.6 | 6.28 | |

| 2 | 5 | 16 | 1 | 2 | 19.6 | 6.28 | |

| Aluminum plate | 0.5 | 1 | 1 | 1 | 2 | 19.6 | 1.08 |

| 0.8 | 3 | 3 | 1 | 2 | 19.6 | 1.72 | |

| 1.5 | 2 | 2 | 1 | 2 | 19.6 | 3.24 | |

| 2 | 4 | 16 | 1 | 2 | 19.6 | 4.23 |

Picture of end product

| Application in air conditioner | Application in public chair |

Production Machines

| Perforated sheet machine | Perforated sheet material |

Related Names

Metal Screens | Perforated Metal Plate | Architectural Metals

Links:https://globefindpro.com/products/85571.html

-

Plastic Mesh

Plastic Mesh

-

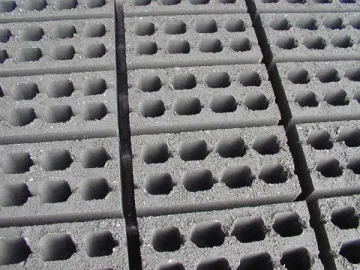

QWT12A4 Automatic Concrete Block Production Line

QWT12A4 Automatic Concrete Block Production Line

-

Swimming Pool Heat Pump Parts

Swimming Pool Heat Pump Parts

-

PVC Coated Hexagonal Wire Mesh

PVC Coated Hexagonal Wire Mesh

-

Shade Netting

Shade Netting

-

Frame Wire Mesh Fence

Frame Wire Mesh Fence

-

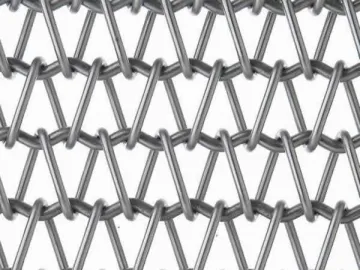

Chain Driven Wire Mesh Conveyor Belt

Chain Driven Wire Mesh Conveyor Belt

-

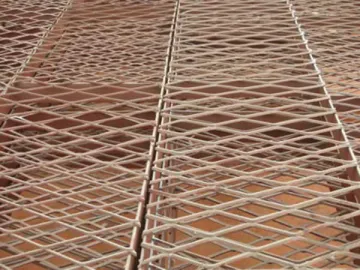

Steel Expanded Wire Mesh

Steel Expanded Wire Mesh

-

QT2-30 Concrete Block Making Machine

QT2-30 Concrete Block Making Machine

-

ACS Series

ACS Series

-

QM5-18 Concrete Block Making Machine

QM5-18 Concrete Block Making Machine

-

BTS Mini Series

BTS Mini Series