PET Strap Making Machine

PET Strap Making Machine

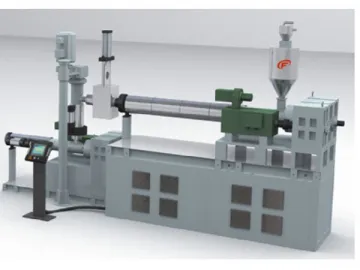

PET strap making machine makes use of the PET scrap to carry out production. In accordance with the customer needs, our specially designed single or twin screw extruder is optional to fit into this machine. Both head and mold are designed to satisfy our users. The same mold can produce different specifications of product. The advanced design of screen changer can help prevent the material from leakage.

Thanks to the static extension machine, this PET strap making machine can not only be used for cooling at a constant temperature, but also strengthen the tensile strength of the finished product. Its melt filter contains two pistons, which has the exhaust port for reflux melting. The double station winding machine features simple operation and convenient reel alternation. In addition, the PLC system can control the whole production line, which is reliable to use and can reach the effect of complete plasticizing and stable extrusion.

Technical Parameters

No | Line Spec | Capacity (kg/h) | Strap Size | Power Consumption | Cooling Type |

1 | 65single line | 50-60 | 9-20 | 40-50kW | Water Cooling |

2 | 65double line | 50-60 | 9, 11, 13, 16 | 40-50kW | Water Cooling |

3 | 75single line | 80-9 | 9-25 | 55-60kW | Water Cooling |

4 | 75double line | 110-120 | 11, 13, 16, 19 | 55-60kW | Water Cooling |

5 | 90double line | 120-160 | 9, 12.7, 16, 19 | 70-90kW | Water Cooling |

6 | 120 four strap line or75 parallel screw line | 250 | 32, 25, 19 (double)16, 12.7, 9 (four) | 150-170kW | Water Cooling |

Related Names

Polyester Strap Making Machine | Plastic Band Production Line

Links:https://globefindpro.com/products/87160.html

-

PP Super Mute Drainage Pipe Production Line

PP Super Mute Drainage Pipe Production Line

-

PE Drip Irrigation Tape Making Machine

PE Drip Irrigation Tape Making Machine

-

PE Waterproof Sheet / Geomembrane Fabrication Machine

PE Waterproof Sheet / Geomembrane Fabrication Machine

-

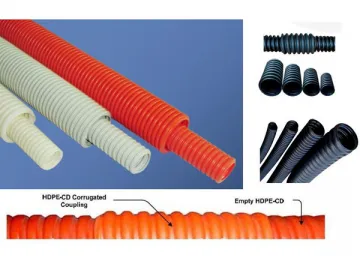

PE/PP/PVC Single Corrugated Pipe Manufacturing Equipment

PE/PP/PVC Single Corrugated Pipe Manufacturing Equipment

-

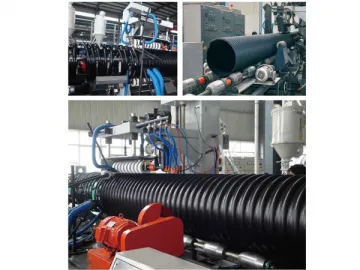

Steel Reinforced PE Spiral Corrugated Pipe Making Machine

Steel Reinforced PE Spiral Corrugated Pipe Making Machine

-

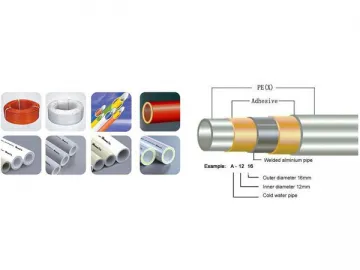

PEX/AL/PEX Composite Pipe High Speed Extrusion Machine

PEX/AL/PEX Composite Pipe High Speed Extrusion Machine

-

3PE Anticorrosion Steel Pipe Production Line

3PE Anticorrosion Steel Pipe Production Line

-

High Efficiency and Energy Saving Three Stage Venting and Filtering Plastic Extruder

High Efficiency and Energy Saving Three Stage Venting and Filtering Plastic Extruder

-

Plastic Artificial Turf Mat Production Line

Plastic Artificial Turf Mat Production Line

-

Single Shaft Shredder and Crusher

Single Shaft Shredder and Crusher

-

PVC Skinning Foam Board Extrusion Machine

PVC Skinning Foam Board Extrusion Machine

-

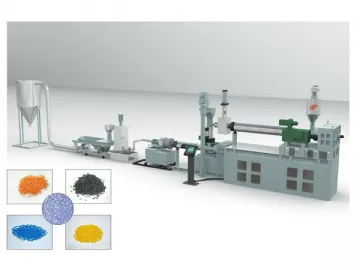

High Efficiency Three Stage PE/PP/PVC Pelletizing Line

High Efficiency Three Stage PE/PP/PVC Pelletizing Line