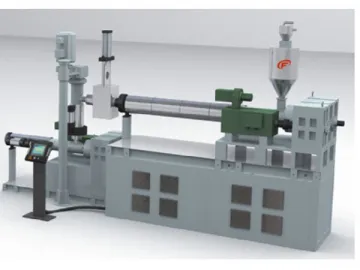

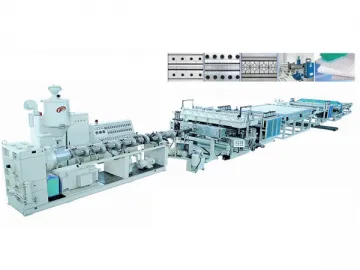

PVC Skinning Foam Board Extrusion Machine

PVC Skinning Foam Board Extrusion Machine

PVC skinning foam board extrusion machine primarily consists of counter rotating parallel twin screw extruder, plate die, vacuum sizing, ten roller traction and other auxiliary parts. It can be extensively available in high end cabinet furniture, advertising lettering material, building decoration material, as well as automobiles, trains and ships for interior decoration and other aspects.

When designing this production line, we use all kinds of internationally advanced product for reference to optimize our machine set. Thus, our PVC skinning foam board extrusion machine possesses such advantages as uniform plasticizing, low shear rate, high yield and long service life and so on. Its cutting machine comes with PLC control system, which is conducive to length setting and also provides accurate automatic cutting.

Technical Parameters

Description | Parameters |

Material | PVC with rice husk |

Product Size | 1220mm width, 3-20mm thickness |

Production Line Speed | 0.5-1m/min |

Max. Output | 380kg/h |

Overall Dimensions (L×W×H) | 20×3.5×3m |

Weight (Approx) | 10T |

Total Installed Power | 320kW |

Actual Energy Consumption Power | 250kW |

Related Names

Decorative Board Production Machine | Foam Board Extruder

Links:https://globefindpro.com/products/87155.html

-

Single Shaft Shredder and Crusher

Single Shaft Shredder and Crusher

-

Plastic Artificial Turf Mat Production Line

Plastic Artificial Turf Mat Production Line

-

High Efficiency and Energy Saving Three Stage Venting and Filtering Plastic Extruder

High Efficiency and Energy Saving Three Stage Venting and Filtering Plastic Extruder

-

3PE Anticorrosion Steel Pipe Production Line

3PE Anticorrosion Steel Pipe Production Line

-

PET Strap Making Machine

PET Strap Making Machine

-

PP Super Mute Drainage Pipe Production Line

PP Super Mute Drainage Pipe Production Line

-

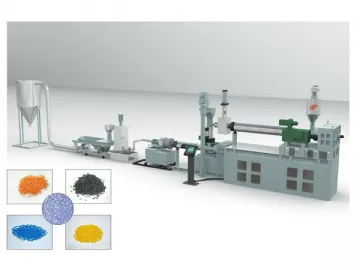

High Efficiency Three Stage PE/PP/PVC Pelletizing Line

High Efficiency Three Stage PE/PP/PVC Pelletizing Line

-

Plastic Grass Mat Extrusion Line

Plastic Grass Mat Extrusion Line

-

PC Plastic Hollow Grid Sheet / Board Extrusion Line

PC Plastic Hollow Grid Sheet / Board Extrusion Line

-

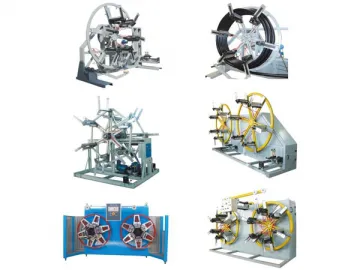

Plastic Pipe Winding Machine

Plastic Pipe Winding Machine

-

WPC Profile Extrusion Line

WPC Profile Extrusion Line

-

PE/PP Plastic Film Recycling Pelletizing Machine

PE/PP Plastic Film Recycling Pelletizing Machine