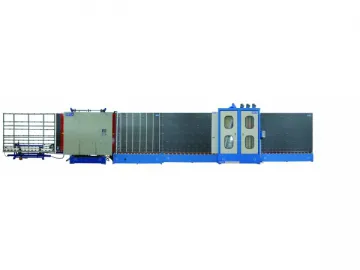

Z Purlin Forming Machine

Z Purlin Forming Machine

Z profile steel is mainly used as purlin in steel structure building, especiallybuildings with a large roof slope angle. As a professional purlin machine manufacturer, we provide customerswith high quality Z purlinforming machines. Punchingand cutting operations are controlled by automatic PLC system, so our Z purlin forming machine has theadvantages of high punching and cutting speed, fast speed regulation, and ahigh degree of automation. As compared with other similar products, the electric motor of our Z purlin forging machine is morereliable and can ensure high accuracy of punching and cutting, low energy cost,and no deformation of cutting cross sections.

Our C purlinforming machine is specially designed to produce high quality C purlin. The roller is forged andundergoes heat treatment so that it is very hard and wear resistant, achieving hardness of 60HRC. The spacer sleeve made of seamless pipe provides convenient replacement,good stability, and reliability. The formingequipment comes with an advanced hydraulic motor from Intermot, whose performance is guaranteed. The moldwhich is used in the punching process consists of a standard guide column andfeather key, and has the advantages of high precision and long service life. Inaddition, all upper mold retaining plates are made of 45# steel. In contrast, it is easy todamage a mold if the retaining plates are made of Q235 steel. The cutting moldis made of Cr12 steel, and its thickness can be up to 32mm, thus ensuring the cutting mold’shardness and long service life. The use of electrical components fromdependable suppliers as well as the computer from Japan Omron helps ensure thesmooth operation of the electrical control system.

In our C purlin formingmachine, the hydraulic unit is installed independently, and a large volume oiltank ensures that the hydraulic system operates normally, even at hightemperatures. This also makes it convenient to replace oil. The oil cylindersare high quality engineering cylinders, and advanced sealing componentsguarantee excellent sealing performance and a long service life. The integralpressing plate is made of steel plate that is 900mm long, 950mm wide, and 35mm thick. It is convenient to maintain the C purlin forming machine due to ouradvanced design.

Technical Specifications of Z PurlinForming Machine

| Dimensions(L×W) | mm | 8800×1500 | |

| Weight | T | 8 | |

| Linear Velocity | m/min | 0-10 | |

| Number of Stations | 13 | ||

| Roller Material | GCr15 | ||

| Max Roller Quenching Thickness | mm | 8 | |

| Roller Quenching Style | Salt Bath Furnace Quenching Hardening | ||

| Roller Main Shaft Material | 40Cr | ||

| Roller Diameter | mm | 80 | |

| Roller Shaft Heat Treatment | Thermal Refining | ||

| Roller Bearing Mode | Deep Groove Ball Bearing 212 | ||

| Rolling Width | mm | 80-300 | |

| Rolling thickness | mm | 1-3 | |

| Motor Model | Radial Piston Motor M8-900 | ||

| Pump Model | Axial Piston Pump 63SCY14-1B | ||

| Motor Power | kw | 15 | |

| Rolling Width | mm | 140-300 | |

| Rolling Height | mm | 55-85 | |

Process Flow

Loading Materials① –Flattening ② -- Molding ③ -- Sizing ④ -- Straightening⑤ --Length Measuring ⑥ -- Punching Circular Lacing Hole ⑦ -- Punching EllipticalConnecting Hole ⑧ – Cutting ⑨

Weare a professional Z purlinforming machine manufacturer and supplier in China. We also offer a floordecking roll forming machine, CNC flame cutting machine, multithread flamecutting machine, assembling machine, and much more.

Links:https://globefindpro.com/products/91601.html

-

Submerged Arc Welding Machine

Submerged Arc Welding Machine

-

Assembling Machine

Assembling Machine

-

High Temperature Air Source Heat Pump

High Temperature Air Source Heat Pump

-

CNC Flame Plasma Cutter

CNC Flame Plasma Cutter

-

DC Inverter Air Source Heat Pump

DC Inverter Air Source Heat Pump

-

CNC Flame Cutting Machine

CNC Flame Cutting Machine

-

Split Air Source Heat Pump

Split Air Source Heat Pump

-

CNC Plasma Cutting Machine

CNC Plasma Cutting Machine

-

Insulating Glass Production Line

Insulating Glass Production Line

-

Tube Solar Water Heater

Tube Solar Water Heater

-

2000 Insulating Glass Production Line

2000 Insulating Glass Production Line

-

Solar Collector

Solar Collector