Continuous Flat MDF/HDF Production Line

ContinuousFlat MDF/HDF Production Line

Performance advantages

1. Energy saving

Continuous production of Jechen MDF production lineand HDF production line ensures low energy consumption. Exactly speaking, acontinuous production line saves up to 20% energy, as compared to anon-continuous one.

2. Material saving

The output products of the continuous flat MDF and HDFproduction line come with good quality. They feature low volume weight anduniform density, and as a result, they require a thin precuringlayer, small sanding and trimming process. This helps save raw materials asmuch as 17%.

3. High production efficiency. Meanwhile, without hydraulic and mechanicalimpact force, the HDF and MDF production line operates steadily. This ensureslong service life.

4. Uniquely design

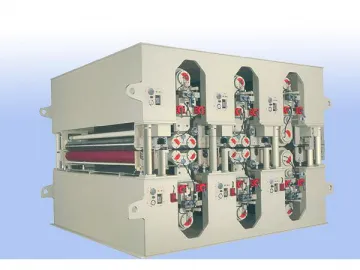

The production line is able to work continuously, andits hydraulic system and heating system is designed according to therequirements on different production steps. Each part is designed into anindependent system with adjustable pressure, temperature and thermal capacity.This design guarantees the precision performance of medium density fiberboardand high density fiberboard production lines.

5. Adjustable thickness

Online adjustment of output productthickness function is available. Without operational interruption, this MDF orHDF production line can achieve thickness adjustment in a few minutes.

6. Continuous flat HDF or MDF production line is designed based on advancedmechanical and electrical integration technologies. It has high requirement onauto detection and auto control. This also ensures reliableproduction line performance.

Technical and design advantages

1. The maximum length of the MDF production line or HDF production line is upto 45.15m.

2. Equipped with a steel strip in width of 1560mm and hot pressing plate in width of 1540mm, the fiberboardproduction line can be used to manufacture fiberboards with a broader range ofwidths. This design also makes the position-adjustment of the steel strip easy,and makes the HDF or MDF production line ideal for the production of basematerials for laminated floor.

3. According to the technical requirements, this MDF production line or HDFproduction line comes with thickened machine frame and enlarged plunger pistondiameter. Meanwhile, the high pressure processing duration is extended, whichsaves time for special technical adjustments.

4. Jechen continuous flat fiberboard production linescome with adjustable material feeding and discharging outlets. Thus, it meetsthe demands for manufacturing fiberboards in different specifications.

5. Branded oil pump and valves for the hydraulic system are utilized. Thisguarantees the steady operation of Jechen HDFproduction line and MDF production line, and high fiberboard quality as well.

6. The electrical system and process control system are acquired from IMAL, aworld famous artificial board production line manufacturer in Italy. Thisalso allows automatic control on production processes and parameter setting.

7. The hot grinding machine, a component of the HDF production line or MDFproduction line, is manufactured by Jechen and Germany’sPALLMANN in alliance, ensuring reliable hot grinding performance. Hence, theoutput wood fiber comes with superior quality, which also ensures the qualityof output fiberboards.

8. The pre-forming machine operates in mechanical force and comes with aflatting device, which improves pre-forming uniformity. Meanwhile, it comeswith a special system to adjust performance according to feedback information.

9. The pre pressing machine is designed with rubber belt and mesh belt as well.This facilitates air exhaustion of fiberboards and therefore increases theboard compactness as well. The electrical and hydraulic system serves to ensurethe uniformity of board thickness.

10. The semi-finished fiberboard is cut by uniquely designed saw which isup-to-date in China.This cutting equipment can ideally satisfy the HDF production line or MDFproduction line’s requirement on cutting speed and cutting quality.

11. The sanding machine is designed based on technologies from Germany BINOSwhich is a world class sanding equipment manufacturer. Hence, it comes withhigh strength machine body and sanded boards come with smooth surface.

12. The online detection facilities are acquired from Italy’s IMAL, offering accurate andtimely feedbacks.

13. Jechen continuous flat MDF and HDF productionline is designed based on over 20 patented technologies, including 8 designpatents.

14. Jechen preheating system is optional before hotpressing process, and a cooling system is also available following hot pressingprocess.

Application

The continuous flat HDF and MDF production lines can be used for themanufacture of medium density fiberboard and high density fiberboard withthickness ranging from 2mmto 38mm.

We at Jechencan supply following three types of medium density fiberboard production lineor hardboard production line:

1. The production line offers an annual production capacityof 80,000-150,000 m3 fiberboard, and the fiberboard width produced is 4 feet.

2. The one offers an annual production capacity of 80,000-200,000 m3fiberboard, and fiberboard width produced is 6 feet.

3. The one offers an annual production capacity of150,000-400,000 m3fiberboard, and fiberboard width produced is 8 feet.

Technical parameters

| Model | Fiberboard width (feet) | Hot pressing plate length (M) | Plate quantity for composing machine frame | Annual production capacity (m3/y) | Remark |

| Y849-18.59 | 4 | 18.59 | 21 | 8 | Suitable for thin board production |

| Y889-18.59 | 8 | 18 | |||

| Y848-21.91 | 4 | 21.91 | 25 | 8 | Not recommended |

| Y888-21.91 | 8 | 18 | |||

| Y847-25.23 | 4 | 25.23 | 29 | 10 | Standard configuration |

| Y887-25.23 | 8 | 20 | |||

| Y846-28.55 | 4 | 28.55 | 33 | 11 | Not recommended |

| Y886-28.55 | 8 | 22 | |||

| Y845-31.87 | 4 | 31.87 | 37 | 12 | Standard configuration |

| Y885-31.87 | 8 | 25 | |||

| Y844-35.19 | 4 | 35.19 | 41 | 13 | Not recommended |

| Y884-35.19 | 8 | 27 | |||

| Y843-38.51 | 4 | 38.51 | 45 | 15 | Standard configuration |

| Y883-38.51 | 8 | 30 | |||

| Y842-41.83 | 4 | 41.83 | 49 | 16 | Not recommended |

| Y882-41.83 | 8 | 32 | |||

| Y841-45.15 | 4 | 45.15 | 53 | 18 | Suitable for thick fiberboard production |

| Y881-45.15 |

Jechen is a Chinacontinuous flat HDFand MDF production line manufacturer and supplier. We also offercontinuous roller MDF production line, multilayer HDF hot press. Our high qualityproducts are offered at competitive prices. Jechen islocated in China, and thefull chain of manufacturing multi-layer particle board hot press andrefiner, etc. can be completed in China,even in one city. Lower manufacturing cost saves your purchasing cost. The moredetails of each product are shown on the page with description.

Links:https://globefindpro.com/products/108852.html

-

MDF and HDF Production Line (Fiberboard)

MDF and HDF Production Line (Fiberboard)

-

Golf Cart Shell

Golf Cart Shell

-

Sailing Boat Mast

Sailing Boat Mast

-

Hemming Machine

Hemming Machine

-

Small Aircraft Wing Mold

Small Aircraft Wing Mold

-

Wind Turbine Blade Mold

Wind Turbine Blade Mold

-

Refiner

Refiner

-

Sander (2, 4, 6 Sanding Head)

Sander (2, 4, 6 Sanding Head)

-

Multi-layer MDF/HDF Hot Press

Multi-layer MDF/HDF Hot Press

-

Wind Turbine Nacelle Cover Mold

Wind Turbine Nacelle Cover Mold

-

Continuous Roller MDF/HDF Production Line

Continuous Roller MDF/HDF Production Line

-

Luxury Composites Yacht Hull

Luxury Composites Yacht Hull