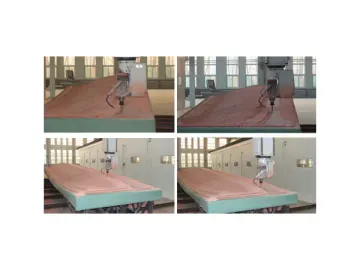

Hemming Machine

Hemming Machine

Features

1.The hemming machine easily forms the hems.

2. The hemming machine is highly efficient.

3. The hemming machine is fully automatic.

Application

The products of the hemmingmachine are used for the surface of desks andother areas.

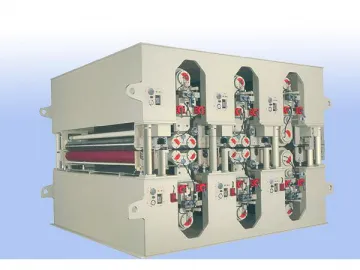

Technical Specifications

| Material | Galvanized, Pre painted Steel Grades D (50 KSI Min.) & E (80 KSI Min.) |

| Thickness | 0.3-0.7mm |

| Forming Speed | 20m/min, Single Speed/td |

| Cut Lengths | 50.8mmMinimum, 533.4mm |

| Blank Width | - 3 ¼” Minimum, 39” Maximum |

Materials

| Model | YD-Hems |

| Material | # 45 Steel Material |

| Roll Forming Material | #45 Steel base / 40CR Steel HRC 48-52 Roller |

| Cutting Material | Cr12 Quenched 58-62 |

| Punching Material | Cr12 Quenched 58-62 or Cr15 Bearing Steel |

| PLC | PLC Panasonic →Touch screen Made in Taiwan →Transducer Yaskawa →Encoder Omron |

| Bearing | National Brand |

Equipment Maintenance

Meticulous daily maintenance playsan important part in extending the hemming machine’s operation time and thequality of the rolling plank. Thefollowing steps should be part of the machine’s daily production and usageroutine.

1. Regularly lubricate the outside parts of the hemmingmachine, i.e., driving chain, etc.

2. Regularly wipe the surface of roller,particularly when working outside. If you do not use the machine a long time of time, youshould daub lube in the roller surface. Make sure you clean it thenext time you use the machine.

3. If the hemmingmachine is not used for a long period of time, make sure youcover it with plastic or cloth. Avoidgetting rain on the machine or the machine becoming damp, especially theelectric control box.

4. Make sure the cuttingsystem is lubricated whennecessary.

5. Check the hydraulic station often and the oil quantity of thedeceleration machines. Add more oil if the oillevel is low.

6. Check the electric appliances box and every leads conjunction circumstance of the hemmingmachine. Dust the machine often.

Packaging

The hemming machine is wrapped and coveredwith film making the package seaworthy. The legs of the machine are fixedwith angle steel and heavy screws.

Yuanding is a majormanufacturer of hemming machines, based in China. We offer various types of products such ashemming machines, tube welding machines, corrugated tile roll forming machines,etc. Our products are high quality andcompetitively priced. We can supply the fullchain of manufacturing downspout pipe forming machines and roofing tile rollforming machines right here in China. Our lower manufacturing cost can save your purchasing cost. More details on each of our products are shownon the description page.

Links:https://globefindpro.com/products/108859.html