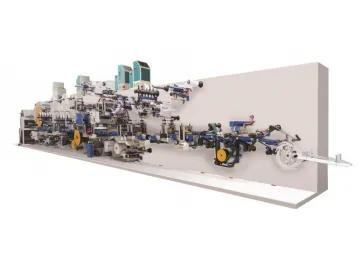

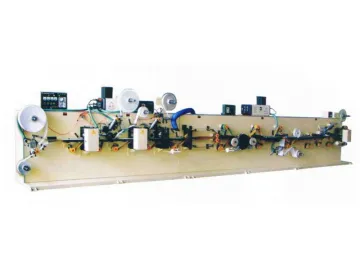

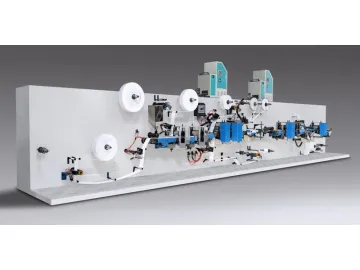

Flexo Printing Press

Roll-to-roll printing machine for coated and uncoated fabric combines outstanding print quality in 4, 6 or 8 colors

Applications:

This flexo printing press features a flexible configuration for continuous dual sided printing, label printing, UV glazing, embossing, die-cutting, laminating, gold blocking, slitting, and other printing processes. It can be used to print on woven bags as well as other flexible packaging products and labels. Technical specifications

Features

The integral steel cast machine frame guarantees stable operation of the flexo printing press. The main motor applies frequency stepless speed regulating. Feeding and rewinding are controlled by a magnetic particle clutch and clutch control. The unwinding unit is controlled by an automatic skew detection sensor. Ceramic anilox rolls offer a long service life, wear resistance and corrosion resistance, which is advantageous in reducing the number of times the anilox roll needs to be changed, and thus, improves the printing efficiency. The printing unit is adjustable by 360°. Each printing unit is equipped with a group of infrared drying devices or interchangeable UV drying devices. When the machine stops, the ink rolls automatically stop and print out to prevent the ink from drying out. The roll feeding, printing, glazing, auto infrared drying, laminating and rewinding processes are all performed in a single pass.

If you have any questions about this product please call us or contact us using the form below.

Tianye’s flexo printing press is designed to simultaneously print on a single side or both sides of the substrate, with a printing capacity of 80m/min. Operators can set the printing quantity or printing meters. Once the printing parameters are set, the printing press will prompt the start of the printing process.

Applications:

This flexo printing press features a flexible configuration for continuous dual sided printing, label printing, UV glazing, embossing, die-cutting, laminating, gold blocking, slitting, and other printing processes. It can be used to print on woven bags as well as other flexible packaging products and labels. Technical specifications

| Model | SBY-4800 | SBY-6800 |

| Printing color | 4 color | 6 color |

| Printing style | Flexo, roll to roll 4 0, 3 1, 2 2 | Flexo, roll to roll 6 0, 5 1, 4 2, 3 3 |

| Max. width of printed material | 800mm | 800mm |

| Max. width of printing | 700mm | 700mm |

| Max. length of repeat printing | 500 - 1300mm | 500 - 1300mm |

| Thickness of plate and tape | 4.0 - 6.0mm | 4.0 - 6.0mm |

| Register precision | ±0.50mm | ±0.50mm |

| Printing capability | 50 - 80m/min | 50 - 80m/min |

| Max. dia. of unwinding | 1200mm | 1200mm |

| Max. dia. of rewinding | 1200mm | 1200mm |

| System installed power | 15kw | 15kw |

| Normal operational power (approx.) | 10kw | 10kw |

| Overall dimension (L×W×H) | 13000×2150×2250mm | 13000×2150×2800mm |

The integral steel cast machine frame guarantees stable operation of the flexo printing press. The main motor applies frequency stepless speed regulating. Feeding and rewinding are controlled by a magnetic particle clutch and clutch control. The unwinding unit is controlled by an automatic skew detection sensor. Ceramic anilox rolls offer a long service life, wear resistance and corrosion resistance, which is advantageous in reducing the number of times the anilox roll needs to be changed, and thus, improves the printing efficiency. The printing unit is adjustable by 360°. Each printing unit is equipped with a group of infrared drying devices or interchangeable UV drying devices. When the machine stops, the ink rolls automatically stop and print out to prevent the ink from drying out. The roll feeding, printing, glazing, auto infrared drying, laminating and rewinding processes are all performed in a single pass.

If you have any questions about this product please call us or contact us using the form below.

Scan QR to Read

Links:https://globefindpro.com/products/11495.html

Links:https://globefindpro.com/products/11495.html

Recommended Products

-

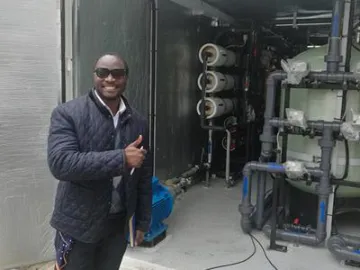

Residential Reverse Osmosis Systems in an Island of Mauritania

Residential Reverse Osmosis Systems in an Island of Mauritania

-

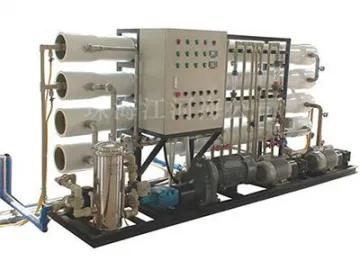

Wastewater Treatment and Recycling Reverse Osmosis and Ultrafiltration System for Water Reuse

Wastewater Treatment and Recycling Reverse Osmosis and Ultrafiltration System for Water Reuse

-

Automatic Solutions for Underpad

Automatic Solutions for Underpad

-

Lab Water Purification System RO-EDI Water Treatment System, Electrodeionization System

Lab Water Purification System RO-EDI Water Treatment System, Electrodeionization System

-

Purified Water Plant, Reverse Osmosis Water Filtration System

Purified Water Plant, Reverse Osmosis Water Filtration System

-

RL-YNK-300, Production Line for Baby Diaper

RL-YNK-300, Production Line for Baby Diaper

-

Custom Solutions for Pantyliner

Custom Solutions for Pantyliner

-

RL-HD-300, Production Line for Panty Liner

RL-HD-300, Production Line for Panty Liner

-

RL-HLD-150, Production Line for Disposable Underpads

RL-HLD-150, Production Line for Disposable Underpads

-

Seawater Desalination Plant in Iran Offshore Oil Platform

Seawater Desalination Plant in Iran Offshore Oil Platform

-

RL-RD-200, Production Line for Nursing Pad

RL-RD-200, Production Line for Nursing Pad

-

Containerized Seawater Desalination System

Containerized Seawater Desalination System

Hot Products