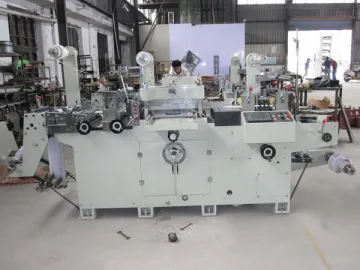

Intermittent Rotary Die Cutting Machine

Characteristics

1. Our intermittent rotary die cutting machine is a new-type die cutter designed by integrating optics, electrics and mechanics theories. It is composed of 6 units, including unreeling unit, web guiding unit, film laminating unit, precision register and die cutting unit, slitting unit, product forming unit and rewinding unit.

2. This machine is available for either intermittent die cutting or rotary die cutting. For the former, the tension for winding, unwinding and web guiding should be consistent, and product dislocation won't happen during conveying.

3. We adopt magnetic roller for intermittent die cutting. You only need to replace die cutting tool without roller replacement when applying die cutting to different products. Intermittent die cutting mode is characterized by fast speed, high precision, easy operation and low cost.

4. Our intermittent rotary die cutting machine is perfect for large, medium and small volume label die when high-quality processing is required. In virtue of touch screen operation and easy roller replacement, die cutting efficiency and quality are largely enhanced, bringing more profits to you.

5. This device is optimal for printing factories. Besides, we also provide flatbed die cutting machine, paper roll die cutting machine and other machines to meet your special needs.

Application Scope

Our intermittent rotary die cutting machine is widely applied in following fields:

2. Dustproof materials: Cotton pad, high-density foam, cotton for filtration, dust screen, non-woven fabric, etc.

3. Shake-proof products: Resilient rubber gasket, rubber, transparent foot pad, Poron pad, 3M pad, anti-flaming EVA, PE, etc.

4. Insulating materials (I Grade): Our intermittent rotary die cutting machine is also applicable for fireproofing vulcanized fiber, aluminum foil, copper foil, PVC, PET, kraft paper, sponge sheath, pearl cotton sheath, etc.

5. EMI (electro-magnetic interference) shielding materials: Copper foil, aluminum foil, conductive fabric, wave-absorbing materials, etc.

6. Heat-resistant and thermal insulation materials: Silicone sheet, transparent mica sheet, fiber cloth, thermal insulation cotton and cloth, etc.

7. Paper packaging materials: Corrugated paper, wrapping paper, paper board, etc.

Technical Parameters

| Model | FG-JX320 |

| Speed (rotary die cutting) | 120m/min. |

| Length (rotary die cutting) | 190.5-539.75mm |

| Speed (intermittent die cutting) | 65m/min. |

| Length (intermittent die cutting) | 100-350mm |

| Width for die cutting | 300mm |

| Roll width | 320mm |

| Unwinding diameter | 600mm |

| Winding diameter | 600mm |

| Positional accuracy | ±0.1 |

| Slitting width | 20mm |

| Power voltage | 380V, 3 phases |

| Overall dimension | 2850×1000×1500mm |

| Total power | 15KW |

| Weight | 2400kg |

Samples

Links:https://globefindpro.com/products/44875.html

-

Paper Slotting Machine

Paper Slotting Machine

-

Dental Chair Unit, ZC-S300 Dental Chair Package

Dental Chair Unit, ZC-S300 Dental Chair Package

-

Rotogravure Printing Machine

Rotogravure Printing Machine

-

PE Coated Paper Cup Bottom

PE Coated Paper Cup Bottom

-

Sterilizer Bag

Sterilizer Bag

-

DC-35 Portable Freezer

DC-35 Portable Freezer

-

Creasing and Cutting Machine

Creasing and Cutting Machine

-

DC-35P Portable Freezer

DC-35P Portable Freezer

-

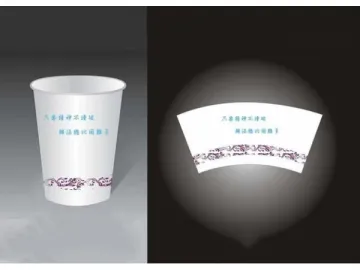

Printed Paper Cup Fan

Printed Paper Cup Fan

-

Flexographic Printing Machine with Three Die Cutting Stations

Flexographic Printing Machine with Three Die Cutting Stations

-

DC-220 Upright Fridge and Freezer

DC-220 Upright Fridge and Freezer

-

Flatbed Die Cutting Machine

Flatbed Die Cutting Machine