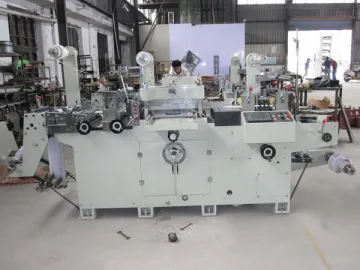

Flexographic Printing Machine with Three Die Cutting Stations

Description

1. The flexographic printing machine with three die cutting stations is more complicated in structure than that with one die cutting station. It comes with one printing station, and one of its three die cutting stations is conductive to paper slitting, which cannot be realized by the flexographic printing press that only has one die cutting station and has no paper slitting function.

2. This machine is provided with two types, i.e. FG-F320-5D and FG-F480-5D. The maximum printing width and maximum roll diameter of the latter respectively are 450mm and 460mm.

3. Conveying table can be optionally configured, by using which, paper products after slitting can be conveyed neatly and orderly.

4. This flexographic printing machine with three die cutting stations can complete unwinding, paper feeding, printing, polishing, IR drying, film laminating, die cutting, slitting and winding at one time, perfect for printing factories. Generally, it is applicable for printing commercial bills, top-grade adhesive materials, tags, paper sheets, plastics, films, aluminum foils and many other materials.

5. Our flexo printing machine with three die-cutting stations requires that the thickness of printing material should be less than 0.25mm, and the thickness of film should be 0.02mm to 0.5mm. (The film shouldn't be stretched.)

6. Resin printing plate either 1.7mm or 1.14mm thick is used by this flexographic printing machine with three die cutting stations.

7. To better cater for your needs, we also provide resin printing plate making machine, resin printing plate exposure machine, slitter, die cutter, paper cup forming machine, cake tray making machine and other machines.

Performance Characteristics

1. Through adopting frequency converter, main motor speed is regulated in stepless way, and starting current is well controlled. The converter also reduces required starting voltage, voltage fluctuation of power circuit as well as energy consumption of centrifugal fan and water pump.

2. The printing unit of this flexographic press enables 360-degree registering adjustment.

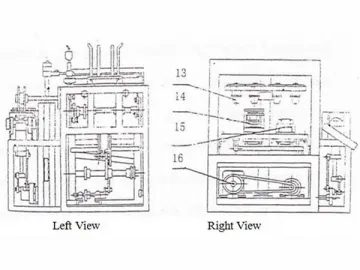

3. The third die cutting station is designed for paper cutting. The top roller and bottom roller of the first and second die cutting stations can be interchanged for front or back die cutting. Besides, this flexographic printing machine with three die cutting stations is fitted with waste rewinding unit.

4. Computer-controlled web guiding device is installed ahead of printing unit, thus proper paper roll position is maintained during the whole printing process.

5. Magnetic powder brake is adopted for paper unwinding and winding.

6. Automatic detachment and low-speed operation is achievable for ink roller once the flexographic printing machine with three die cutting stations stops working in case of dried ink.

Optional Configurations

1. UV lamp

2. Video inspection system

3. Film laminating device

4. Web guiding mechanism

5. Corona treatment device

6. Conveying table

7. Dual-winding mechanism

Technical Parameters

| Model | FG-F320-5D | FG- F480-5D |

| Printing speed | 60m/min. | 60m/min. |

| Color | 5 | 5 |

| Maximum paper roll width | 330mm | 460mm |

| Maximum printing width | 320mm | 450mm |

| Maximum unwinding diameter | 700mm | 700mm |

| Maximum winding diameter | 700mm | 700mm |

| Printing perimeter | 175-355mm | 175-355mm |

| Registering precision | ±0.1 | ±0.1 |

| Overall dimension | 3730×1150×2550mm | 3730×1280×2550mm |

| Weight | 3500kg | 4000kg |

| Total power | 10.5KW | 15KW |

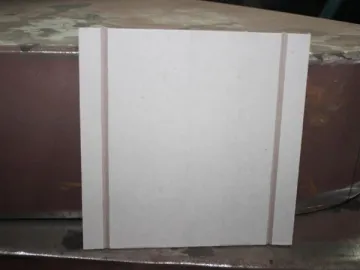

Samples

Links:https://globefindpro.com/products/44870.html

-

Printed Paper Cup Fan

Printed Paper Cup Fan

-

DC-35P Portable Freezer

DC-35P Portable Freezer

-

Creasing and Cutting Machine

Creasing and Cutting Machine

-

Intermittent Rotary Die Cutting Machine

Intermittent Rotary Die Cutting Machine

-

Paper Slotting Machine

Paper Slotting Machine

-

Dental Chair Unit, ZC-S300 Dental Chair Package

Dental Chair Unit, ZC-S300 Dental Chair Package

-

DC-220 Upright Fridge and Freezer

DC-220 Upright Fridge and Freezer

-

Flatbed Die Cutting Machine

Flatbed Die Cutting Machine

-

Double PE Coated Paper Cup Forming Machine

Double PE Coated Paper Cup Forming Machine

-

Slitter Rewinder

Slitter Rewinder

-

Single PE Coated Paper Cup Forming Machine

Single PE Coated Paper Cup Forming Machine

-

XC-70GF 3 Way Camping Freezer

XC-70GF 3 Way Camping Freezer