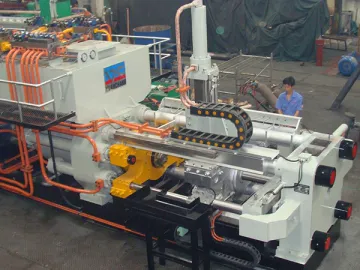

Extrusion Press (for Φ105mm Rod)

Aluminum Extrusion Equipment, Rod Extruder Aluminum Rod Extrusion Machine

Intended for aluminum rods, this extrusion press is a type of indirect extruder, with a hollow raw containing a die. In indirect extrusion press, all profiles are extruded out of the inner bore of raw.

Major Advantages of Aluminum Extrusion Equipment

1. The aluminum rod machine is best known for generating no heat when running, due to no relative movement between container and billet.

2. There is about 25%-30% decrease of extrusion force in this indirect aluminum extrusion system.

3. Welled suited for profiles with smaller cross sectional area, the rod extruder works smoothly and fast even under low temperature.

4. The uniform aluminum flow, small extrusion hole and low residual pressure assure exceptionally stable mechanical capacity of extruded rods.

Technical Data of Extrusion Machine

| Model (Al) | Rated pressure (MPa) | Size of standard aluminum billet (mm) | Max. circumcircle of profile (mm) | Max. width of profile (mm) | Size of die (mm) | Central height of machine (mm) | Total power (kW) | |

| Metric ton | Short ton | |||||||

| XJ-2500 | XJ-2750 | 21 | Φ229×920 | Φ105 | 105 | Φ238×120 | 1650 | 550 |

| XJ-2750 | XJ-3000 | 25 | Φ229×970 | Φ105 | 105 | Φ238×120 | 1650 | 550 |

Applications

Aluminum rods and plates mainly function as curtain rails, shower cabins, shelves supports, fly screen system, rolling shutter, to name a few.

Notes

1. Limited by the hollow raw, the applied load cannot exceed a certain range.

2. Limited by the size of die, profiles with complex cross section cannot be processed.

Links:https://globefindpro.com/products/53931.html

-

Industrial Color Sorter

Industrial Color Sorter

-

Tea Color Sorter

Tea Color Sorter

-

Window Frame Sanding Machine

Window Frame Sanding Machine

-

Double Action Extrusion Press for Φ200mm-Φ80mm Aluminum Seamless Tube

Double Action Extrusion Press for Φ200mm-Φ80mm Aluminum Seamless Tube

-

FZQT10-20 Block Making Machine

FZQT10-20 Block Making Machine

-

Extrusion Press (for Φ220mm Rod)

Extrusion Press (for Φ220mm Rod)

-

Double Action Extrusion Press for Φ120mm-Φ65mm Copper Seamless Tube

Double Action Extrusion Press for Φ120mm-Φ65mm Copper Seamless Tube

-

FZQT8-20 Block Making Machine

FZQT8-20 Block Making Machine

-

Double Action Extrusion Press for Φ60mm-Φ30mm Copper Seamless Tube

Double Action Extrusion Press for Φ60mm-Φ30mm Copper Seamless Tube

-

Double Action Extrusion Press for Φ90mm-Φ45mm Copper Seamless Tube

Double Action Extrusion Press for Φ90mm-Φ45mm Copper Seamless Tube

-

Double Action Extrusion Press for Φ170mm-Φ70mm Aluminum Seamless Tube

Double Action Extrusion Press for Φ170mm-Φ70mm Aluminum Seamless Tube

-

Extrusion Press (for Φ120mm Rod)

Extrusion Press (for Φ120mm Rod)