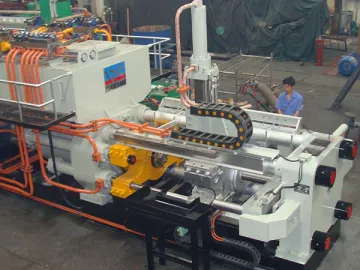

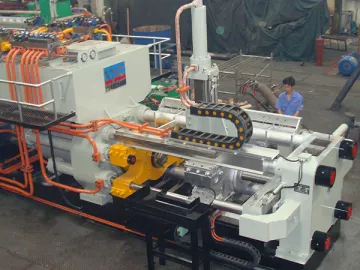

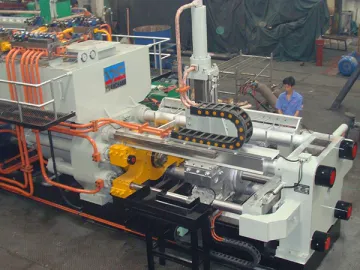

Extrusion Press (for Φ220mm Rod)

Aluminum Rod Extrusion Equipment, Aluminum Extrusion Press, Aluminum Extrusion System

When it comes to direct and indirect extrusion press, each has special features and benefits. In direct extrusion, the billet is driven forward by the ram, which will surely generate friction at the die and container wall. Thus, higher pressure will be required for direct extrusion.

In indirect extrusion, the billet is kept still and the ram is hollow. When processing, the extruded rod passes through the inner bore at a reverse direction to the movement of ram. The indirection extrusion cause no heat or friction however there is a limit on load applied.

Advantages of Indirect Extruders over Direct Extruder

1. No friction or heat.

2. 25%-30% extrusion force will be reduced.

3. Suitable for handling profiles with a small cross sectional area, under low temperature and at high speed.

4. Mechanically capable aluminum rods can be got thanks to uniform aluminum flow, small extrusion hole and low residual pressure.

Technical data of Aluminum Rod Extrusion Equipment

| Model (Al) | Rated pressure (MPa) | Size of standard aluminum billet (mm) | Max. circumcircle of profile (mm) | Max. width of profile (mm) | Size of die (mm) | Central height of machine (mm) | Total power (kW) | |

| Metric ton | Short ton | |||||||

| XJ-5500 | XJ-6000 | 25 | Φ356×1500 | Φ220 | 220 | Φ380×200 | 2150 | 1200 |

Applications

Applications of aluminum rods are found in home decoration, road transport, bridge construction, etc.

Notes

1. Limited by the hollow raw, the applied load cannot exceed a certain range.

2. Limited by the size of die, profiles with complex cross section cannot be processed.

Links:https://globefindpro.com/products/53939.html

-

Double Action Extrusion Press for Φ180mm-Φ80mm Copper Seamless Tube

Double Action Extrusion Press for Φ180mm-Φ80mm Copper Seamless Tube

-

FZQT6-15 Block Making Machine

FZQT6-15 Block Making Machine

-

Extrusion Press (for Φ95mm Rod)

Extrusion Press (for Φ95mm Rod)

-

Extrusion Press (for Φ145mm Rod)

Extrusion Press (for Φ145mm Rod)

-

Extrusion Press (for Φ170mm Rod)

Extrusion Press (for Φ170mm Rod)

-

FZQT6-18 Block Making Machine

FZQT6-18 Block Making Machine

-

FZQT10-20 Block Making Machine

FZQT10-20 Block Making Machine

-

Double Action Extrusion Press for Φ200mm-Φ80mm Aluminum Seamless Tube

Double Action Extrusion Press for Φ200mm-Φ80mm Aluminum Seamless Tube

-

Window Frame Sanding Machine

Window Frame Sanding Machine

-

Tea Color Sorter

Tea Color Sorter

-

Industrial Color Sorter

Industrial Color Sorter

-

Extrusion Press (for Φ105mm Rod)

Extrusion Press (for Φ105mm Rod)