Breakfast Corn Flakes Processing Line

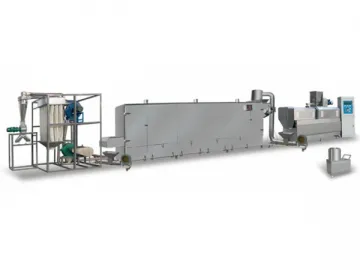

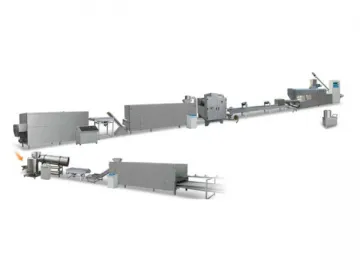

The breakfast corn flakes processing line featured on this page is built on world-leading extrusion technology. A high level of automation allows the food processing equipment to do mixing, pressing, drying and extrusion in one run. The resultant corn flakes make a perfect breakfast as it can be re-infused many times without losing its flavor or structural integrity, all the while giving a smooth mouth feel and rich corn taste over each brew.

Depending on the demand for corn flakes in your local market, we can supply breakfast corn flakes processing lines in different capacity ranges including 100-200kg, 150-300kg, and 250-400kg. Over our history of product development and innovation, the breakfast corn flakes processing line has experienced several major improvements which bring the equipment to what it is today.

The first improvement is using cornmeal instead of previous corn kernels as raw material. The second change is to the extruder, as we now use a double-screw extruder for continuous extrusion. This improved extrusion method produces more uniform size grains with better taste. The last innovation is in the drying zone where we subject corn flakes to a higher temperature which brings out the best flavor in them.

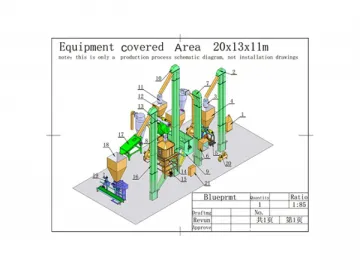

Production Process

Cornmeal→Batching→Cooking(pre-conditioning), extrusion→Cut to size→Pre-drying→Tablet press→Drying at high temperature→Corn flakes

Components

1.

2.

3.

4. Blower

5. Tablet press

6. Belt conveyor

7.

8. Belt dryer

9. Rotary drum dryer (baking)

10. Elevator

11. Spray coating

12. Belt conveyor

13. Drying oven

14. Cooling conveyor

| Model | Installed Power | Power Consumption | Main Motor Power | Yield | Installed Dimensions |

| 35KW | 22-30KW | 22KW | 100-200KG | 15×2.5 ×4M | |

| 45KW | 30-35KW | 30KW | 150-300KG | 16×2.5 ×4M | |

| 55KW | 35-40KW | 37KW | 300-500KG | 27×2.5 ×4.5M |

Links:https://globefindpro.com/products/58924.html