Stationary Type Stabilized Soil Mixing Plant

Batching System

1. With simple structure, the batch bin of our stationary type stabilized soil mixing plant is easy to install and transport. Each batch hopper is fitted with screen.

2. The electronic belt scale installed within the aggregate hopper can achieve continuous weighing. Variable-frequency speed-regulation motor ensures high measuring precision.

3. At the discharge opening, there is an alarm to indicate material shortage.

4. A vibrator is installed onto the wall of the fine-grained material bin to prevent pack set.

5. The belt conveyor is equipped with emergency stop switch to protect the safety of equipment and operators.

Powdery Material Supply System

1.There is a dust collector installed on the top of the pulverized material silo to help remove dust and protect environment.

2. The silo is also installed with an air blaster to prevent caking and allow maximum storage capacity.

3. A steady flow bin ensures an accurate, reliable weighing of cement.

Water Supply System

The water level can be automatically controlled. Users can set an alarm on the tank to send warnings when the water reaches the upper limit or is reduced to the lower limit. The alarm also can be interlocked with the water pump. For high energy efficiency, a variable-frequency motor is adopted to pump exact amount of water into the tank.

Mixing System

1. The mixing system of our mixing plant adopts the dual horizontal axes forced mixer to ensure an even mixing.

2. There is a door release unit fitted at the bottom of the mixing bin, which facilitates cleaning.

3. The mixing bin comes with no liner plates. This design reduces paddle wear. For durability and longevity, the mixing paddles are constructed from wear-proof materials.

Finished Products Conveying and Storage System

1. There are various devices installed onto the conveyor to prevent the durable belt from mistracking.

2. The belt is made from small, individual pieces. This modular design allows easier installation and transportation relative to previous models.

3. The optimized design of our finished product bin prevents the blended ingredients separating from one another. It is highly stable to use.

4. The vibrated is installed on the wall of finished product bin to prevent the products clogging in the corners.

| Model | MWCB300 | MWCB400 | MWCB500 | MWCB600 |

| Mixer Type | Dual Horizontal Axes Forced Mixer | |||

| Rated Productivity(t/h) | 300 | 400 | 500 | 600 |

| Aggregate Bin Volume(m3) | 3×12 | 4×12 | 4×12 | 4×15 |

| Aggregate Diameter(mm ) | ≤60 | |||

| Batching Precision | Aggregate±2, cement±1, water±1 | |||

| Feeding Height(m) | 3.9 | 4.1 | 4.1 | 4.5 |

| Discharging Height (m) | 3.5 | 3.5 | 3.5 | 3.8 |

| Total Power KW | 95 | 105 | 120 | 140 |

| Note1. The power of spiral conveyor is not included in the total power.2. The number of bins and their capacity can be made to order. 3. The above data are subjected to change without prior notice. The table is for reference only. | ||||

Control System

1. The control system of our mixing plant can switch freely between manual, semi-automatic, and automatic control modes. The central industrial personal computer presents the dynamic production process on the screen in multiple languages. It features an elegant, visual display.

2. Controlled by the PLC system, the motor can be started or stopped via a button. Fault detection and alarming functions ensure a safe operation. Weighing signals are directly send into the PLC system to avoid data transfer interruption and improve response speed. Multiple materials are automatically fed into the mixer following the preset mixing order so as to achieve the synchronization between material feeding and mixing.

3. Extra care must be taken to ensure electrical safety and prevent accidents during production and machine inspection and repair. The equipment should be grounded at multiple points. Safety signs should be set up. All these measures can ensure the safety of operators and equipment.

4. At the cement hopper, feed level can be automatically displayed. The air blaster prevents the cement from caking. When the water reaches the upper limit level, or is reduced to lower limit level, the alarm will be set off. Correspondingly the water pump will stop supplying water or start adding water to the tank. A vibrator is installed on the aggregate hopper. The hopper is also fitted with an alarm to give warnings of aggregate shortage. The vibrator on the finished product silo is mainly charged with the function of preventing material from clogging in the corners.

5. The control system of our mixing plant has multiple functions, including automatic adjustment of zero point and weighing parameters. It can display and print preset parameters and actual values as well as real-time production report and historical report(including date, time, accumulated production hours, and accumulated material consumption).

6. The detachable control room is spacious and brilliant with secure seal and broad vision. It is damp-proof, dust-free with good thermal and acoustic insulation. There is also an air-conditioner inside the room. Various instrument, alarming equipment, emergency control device, keyboard, and control screen are reasonably and ergonomically arranged in order of production process.

Our company is a specialized stationary type stabilized soil mixing plant manufacturer and supplier in China. We provide a broad range of products, including ready-mix concrete plant, mobile concrete batching plant, stationary asphalt mixing plant, and more.

Related Names

Soil Mixed with Cement, Lime and Fly Ash | High Efficiency Stabilized Soil Mixer | High Accuracy Stabilized Soil Mixing Station | Road Engineering Equipment

Links:https://globefindpro.com/products/62273.html

-

Radar Antennas

Radar Antennas

-

Ferris Wheel

Ferris Wheel

-

Deck Crane

Deck Crane

-

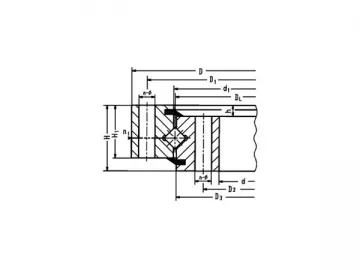

Slewing Bearing Installation and Maintenance

Slewing Bearing Installation and Maintenance

-

Mobile Concrete Batching Plant

Mobile Concrete Batching Plant

-

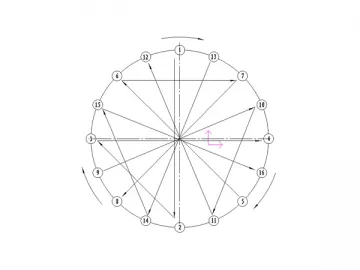

Cross-Roller Slewing Bearing(Without gear)

Cross-Roller Slewing Bearing(Without gear)

-

Carbon Fiber Tube

Carbon Fiber Tube

-

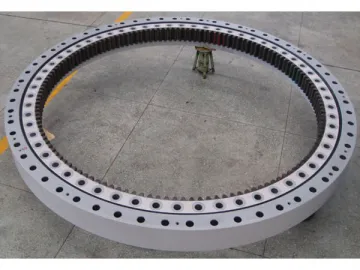

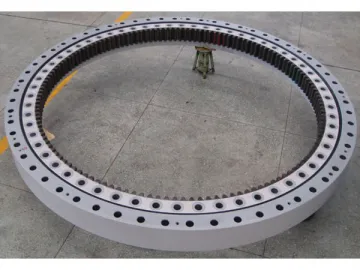

Three-Row Roller Slewing Bearing

Three-Row Roller Slewing Bearing

-

Double Row Ball Slewing Bearing

Double Row Ball Slewing Bearing

-

Four-Point Contact Ball Slewing Bearing (Internal gear)

Four-Point Contact Ball Slewing Bearing (Internal gear)

-

Double Row Ball Slewing Bearing (Internal gear)

Double Row Ball Slewing Bearing (Internal gear)

-

Contract of Slewing Bearing in Maximum Size in China with Shanghai Zhenhua Heavy Industry Co., Ltd.

Contract of Slewing Bearing in Maximum Size in China with Shanghai Zhenhua Heavy Industry Co., Ltd.