Horizontal Form Fill Seal Bagging Machine

Horizontal form fill seal bagging machine is highly distinguished by its compatibility with various filling devices, thus our packaging machine is able to handle powder, liquid, particle and sauce. Based on premium performance, this filling and sealing machine delivers exceptional efficiency, cleanness and precision.

Our horizontal form fill seal bagging machine consists of comprehensive units including film pulling, bag forming, bottom sealing, side sealing, cutting, opening and filling as well as transporting and top sealing, etc. With the aid of electric motor, cams incorporating with the main shaft are responsible for the stable cooperation among all units.

Moreover, the main shaft involves the use of encoder for positioning information, based on which the PLC enables operatives to control the consecutive production process covering film pulling, bag forming, filling, sealing and ejecting. The finished products are manually packaged into cartons or boxes.

Feature

1. Siemens PLC is adopted for ensured reliability and ease of operation.

2. Variable frequency control is applied to the entire production process for stability.

3. All parts of our horizontal form fill seal bagging machine are manufactured with high-precision CNC machines, so as to offer remarkable accuracy and durability. Moreover, the swing clamp is equipped with protractor, maximizing precision.

4. The machine body is made up of 16mm thick steel panel, thus offering impressive stability even at high machine speed.

5. Easy material change and convenient maintenance.

Specification

1. Bag size (W × H × L): Min.: 150 × 200mm, Max.: 315 × 480 × 215mm

2. Bag shape: flat bottom, stand bag, bag with eurohole, bag with round hole, zippered bag

3. Machine speed: 20 to 50 bags/min (the speed is determined by the machine and scale)

4. Voltage: 380V/50Hz

5. Electricity consumption: 3kW

6. Air consumption: 0.3 to 0.9m3/min

7. Noise level: <70dB

8. Net weight: 1800kg

9. Machine dimension (L × W × H): 3935 × 13020 × 1550mm

Workflow

Transporting bag → receiving bag → opening bag → blowing → filling → flatting → sealing → shaping → finished product output

Standard component configuration (customizable)

1. Electronic component

Touch screen, frequency convertor and PLC: Siemens

Sensor and proximity switch: Omron, SMC or Festo

Low-voltage electronic components: Schneider

Temperature controller: Omron

Terminal: Phoenix

2. Pneumatic components: Festo or SMC

3. Main shaft electric motor: Lenz, bag feeding servomotor: Panasonic

4. Parts contact with materials: 304 stainless steel

Links:https://globefindpro.com/products/78425.html

-

Reverse Jet Silo Venting Filter

Reverse Jet Silo Venting Filter

-

Aeration Pad

Aeration Pad

-

MT-BFH Mortar Mixers with Bag Feeding Hopper

MT-BFH Mortar Mixers with Bag Feeding Hopper

-

ZLP500 Suspended Platform

ZLP500 Suspended Platform

-

SMM Series Continuous Mortar Mixer

SMM Series Continuous Mortar Mixer

-

ZLP630 Suspended Platform

ZLP630 Suspended Platform

-

Vibrating Bin Aerator

Vibrating Bin Aerator

-

Horizontal Bag Filling and Sealing Machine

Horizontal Bag Filling and Sealing Machine

-

Steel Suspended Platform

Steel Suspended Platform

-

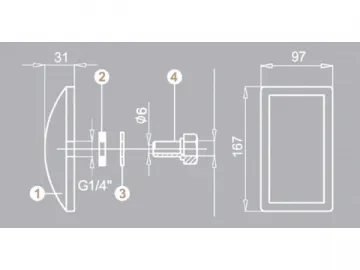

Pressure Relief Valve

Pressure Relief Valve

-

Filter Cartridge, Filter Bag

Filter Cartridge, Filter Bag

-

ZLP630B Suspended Platform

ZLP630B Suspended Platform