CNC Grooving Machine

The CNC grooving machine is a newly-developed high-precision CNC groover, and it makes use of the digital signal control (DSC) system to realize two major functions which are bending and cutting.

Bending

1. Our CNC bending machine could determine required cutting width and depth according to the curvature, whilst unnecessary slotting points are filtered out.

2. When bending metal sheets, the starting position can be set as per needs. Moreover, if the front part of metal sheet is in irregular shape, operators could use shaping function to cut off these waste materials.

3. The material saving mode means our grooving machine will pause automatically when there is not sufficient metal sheet, and will continue working after materials are prepared.

4. As we know, different letters have different bending directions, but our CNC bender automatically distinguishes the differences between inward folding and outward folding, and the grooving width or depth is also adjusted accordingly, thus offering outstanding bending result.

5. Metal sheets usually differ from each other in thickness, and thicker material is obviously more difficult to process. Given this, grooving process can be conducted in several steps, indicating that a deep groove is formed by processing a thin layer of metal each time. In this way, cutting tools are well protected, and deep grooving is also realized.

6. For this grooving machine, all the moving speeds, including blade rotation speed, grooving speed, feeding speed, cutting speed and return speed, could be adjusted separately based on specific condition to obtain better cutting result in a shorter time.

7. The cutting blades are driven by brushless AC servo motor to realize stepless speed regulation, and digital-to-analog conversion technology is also adopted to intelligently control blade rotation speed.

8. Coordination control of multi cylinders guarantees the precision of material feeding, clamping and other actions when grooving.

Cutting

The CNC grooving machine could set depth, width and spacing at various values respectively to cooperate with sine wave generator, triangular wave generator and sawtooth wave generator, thus creating various cutting effects. With the help of diamond blades, delicate edges can be manufactured to decorate organic glass and aluminum alloy.

Features

1. There is a height adjustment system for CNC cutting tools, and this is pioneered by us. This function is aimed at thick or hard materials, because it would groove or cut base materials step by step instead of as a whole. Accordingly, grooving depth and cutting depth are controlled freely.

2. The saw blade is made from tungsten steel, and its rotation behavior is driven by high-power servo motor. Compared with traditional cutting tools, our saw blade is much more durable, and it realizes stable cutting, uniform cut as well as controllable cutting depth. In addition, the rotation speed could be adjusted at any time according to material hardness and grooving depth.

3. The fully automatic DSC software is designed on the basis of our technological research, and this software has been field proven to be a great partner when making metal letters.

4. This mechanical grooving tool automatically calculates if the remaining material is enough for current job, and it will remind users if the answer is no.

In general, this CNC grooving machine could work together with our plasma cutting machine or engraving machine for the purpose of industrial production of metal letters.

Technical Data

| Model | EZ-150 | Unit |

| Grooving width | 200 | mm |

| Grooving method | Servo motor-driven rotary cut | - |

| Grooving depth | Any depth due to layered cutting mode | - |

| Height adjustment | Numerical control for cutting tools | - |

| Power supply | AC 220±10%/50 | V/Hz |

| Total power | 1.2 | kW |

| Overall dimension | 1000×600×1500 | mm |

| Power supply | AC 220±10%/50 | V/Hz |

| Total power | 6 | kW |

| Weight | 660 | kg |

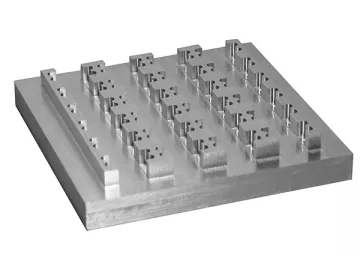

Processing Samples

Links:https://globefindpro.com/products/79168.html

-

Roller Leveler

Roller Leveler

-

Cercon System Compatible Zirconia Block

Cercon System Compatible Zirconia Block

-

Super Translucency Coloring liquid for Zirconia Block

Super Translucency Coloring liquid for Zirconia Block

-

Shutze System Compatible Zirconia Block

Shutze System Compatible Zirconia Block

-

Amann Girrbach CAD/CAM System Compatible Zirconia Block

Amann Girrbach CAD/CAM System Compatible Zirconia Block

-

High Translucency Coloring Liquid for Zirconia Block

High Translucency Coloring Liquid for Zirconia Block

-

Electro-Hydraulic Press Brake

Electro-Hydraulic Press Brake

-

VMK-0088 Key Cutting Machine

VMK-0088 Key Cutting Machine

-

MEII-4840 Mold Engraving Machine

MEII-4840 Mold Engraving Machine

-

MEII-4242SQ Mold Engraving Machine

MEII-4242SQ Mold Engraving Machine

-

MEII-4242 Mold Engraving Machine

MEII-4242 Mold Engraving Machine

-

Heavy Duty Mechanical Shear

Heavy Duty Mechanical Shear