Trailer-Mounted Boom Concrete Pump

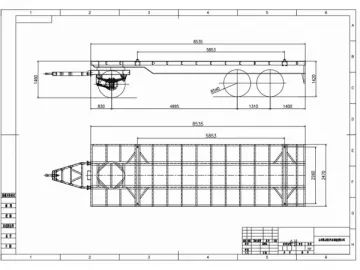

Concrete Boom Trailer

| Max. Vertical Height(m) | 23.2 | 31.6 | 35.7 | 37.8 | 39.9 | 44.3 | 47.1 | 49.4 | 51.3 | 54.3 | 59.5 |

| Horizon Distance(m) | 19.8 | 27.7 | 32 | 34 | 35.7 | 40.5 | 43.3 | 45.6 | 47.5 | 50.2 | 55.5 |

| Truck front H.D (m) | 25.4 | 29.5 | 31.6 | 32.8 | 37.6 | 40.2 | 42.6 | 44.5 | 46.9 | 52.9 | |

| Boom Diameter (mm) | 125 | 125 | 125 | 125 | 125 | 125 | 125 | 125 | 125 | 125 | 125 |

| Max. Discharge Capacity (m ³/h) | 90 | 170 | 170 | 170 | 170 | 170 | 170 | 170 | 170 | 170 | 170 |

| Conveying Time /Min. | 28 | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 32 |

| Legs Capacity (T) | 11 | 20.5 | 20.5 | 21.5 | 22.5 | 28 | 33.5 | 33.5 | 33.5 | 40 | 45 |

| Chassis Brand | HOWO Brand (China) or ISUZU Brand (Japan ) | ||||||||||

Boom Concrete Pump

| Boom and Legs | |

| Boom Vertical Height | 51.3m |

| Horizontal length | 47.5m |

| Vertical Depth | 38.4m |

| Min. Height | 11.3m |

| First Section of Boom | Rotor angle: 92 degree |

| Second Section of Boom | Rotor angle: 180 degree |

| Third Section of Boom | Rotor angle: 225degree |

| Fourth Section of Boom | Rotor angle: 180 degree |

| Section Boom | Rotor angle: 210 degree |

| Turntable Rotor Angle | ±360 degree |

| Front Leg Extend W | 910000mm |

| Back Leg Extend W | 10600mm |

Boom conveying system

| Theoretical Discharge Capacity | Lower Pressure:170m3/h Higher Pressure:120m3/h |

| Theoretical Pumping Pressure | Lower Pressure :8.3MPa Higher Presssure:12MPa |

| Theoretical Pumping Times | Lower Pressure:24.5T/Min Higher Pressure:17T/Min |

| Inner Diameter of Conveying Cylinder | 260mm |

| Conveying Cylinder Distance | 2100mm |

| Hydraulic System | Open type |

| System Oil Pressure | 32MPa |

| Oil Tank Capacity | 700L |

| Water Tank Capacity | 600L |

| Conveying Pipe Diameter | 125mm |

Product Photos

Introduction

The trailer-mounted boom concrete pump is commonly referred to as the line pump. It uses pressure to continuously transfer concrete mixture through the pipeline to various construction sites. From the outside, you can see a long, flexible concrete delivery hose, a big pump that is carried on the trailer chassis, and a telescopic or articulating arm called the boom. Today the boom pump is widely seen on the building, factory, and foundation construction sites. It is easily movable and can be led wherever the concrete needs to be placed.

The power needed for carrying out pumping operation is provided by the trailer engine. During concrete pumping, power is transmitted from the gearbox of trailer to the transfer gear-case that is connected to the pump or rear trailer axle. Imported pump and motor ensure the stability and reliability of the hydroelectric system. The smart motor saves 10% of fuel compared with an ordinary motor. The concrete delivery hose, eccentric reducer, and spectacle-shaped wear plate are all made of highly abrasion-resistant materials for extended use life.

Links:https://globefindpro.com/products/80423.html