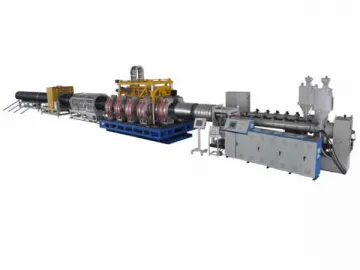

SBG315 UPVC Double Wall Corrugated Pipe Extrusion Line

This SBG315 UPVC double wall corrugated pipe extrusion line is warmly welcomed by customers at home and abroad. Outside diameter of available pipe varies from 110mm to 315mm. In compliance with the demand of plastic market, our company absorbs the progressive technology from foreign companies, and obtains the latest research achievement in the plastic extrusion molding field.

The whole production line adopts one conical twin-screw extruder for production. Its high quality alloy steel composite extrusion head has gone through chrome-plating and polishing treatment process. The corrugator is designed with horizontal structure and chain transmission, accompanied with the forced air cooling system.

The operation of special aluminum-alloy mould block takes advantage of the mechanical type up/down synchronous drive system, plus the advanced self-lubricating system. In this way, both the running accuracy and the pipe quality stability can be well ensured. Moreover, our UPVC double wall corrugated pipe extrusion line employs the professional PLC control system from Germany Siemens Company, which offers such advantages as simple use, reliable operation, and high degree of automation.

Main Technical Parameters

| Components | Model | Overall Dimension(Length ×Width × Height) mm | Total Power (kW) | Weight(kg) |

| Extruder | SJSZ80 | 6000×1500×2500 | 110 (max.) | 7500 |

| Module(Outside Diameter) | SBZG110 (Outside Diameter) | 2000×Φ280 | 20-30 | 1800 |

| SBZG160 (Outside Diameter) | 2000 | |||

| SBZG200 (Outside Diameter) | 2600 | |||

| SBZG250 (Outside Diameter) | 2400×Φ465 | 2800 | ||

| SBZG315(Outside Diameter) | 3000 | |||

| Corrugator | SBCJ315 | 4300 ×1750 ×1800 | 10 (max.) | 5000 |

| Cutting Machine | QG315 | 2900 ×1400 ×2060 | 3.7 | 2500 |

| Belling Machine | SGK315 | 8725×2600×2100 | 20 | 4000 |

Sample

Related Names

Corrugated Tubing Making System Manufacturer | Durable Pipe Venting System | Plastic Processing Equipment

Links:https://globefindpro.com/products/83996.html

-

Chlorpyrifos

Chlorpyrifos

-

PE Steel Strip Reinforced Spiral Pipe Extrusion Line

PE Steel Strip Reinforced Spiral Pipe Extrusion Line

-

Paraquat

Paraquat

-

Rubber Predispersed Masterbatch TMTD

Rubber Predispersed Masterbatch TMTD

-

Rubber Predispersed Masterbatch NOBS-70

Rubber Predispersed Masterbatch NOBS-70

-

Rubber Predispersed Masterbatch IS

Rubber Predispersed Masterbatch IS

-

PEX/Al/PEX Aluminum Composite Pipe Extrusion Line

PEX/Al/PEX Aluminum Composite Pipe Extrusion Line

-

1.8% Abamectin and 3.2% Acetamiprid EC

1.8% Abamectin and 3.2% Acetamiprid EC

-

PE Carbon Spiral Pipe Extrusion Line

PE Carbon Spiral Pipe Extrusion Line

-

Fluazifop 15% EC

Fluazifop 15% EC

-

Atrazine

Atrazine

-

SBG800 HDPE/PP Double Wall Corrugated Pipe Extrusion Line

SBG800 HDPE/PP Double Wall Corrugated Pipe Extrusion Line