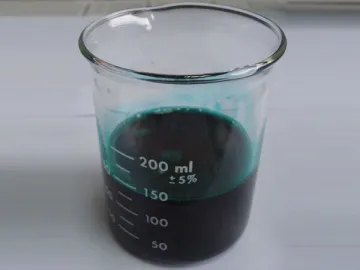

Rubber Predispersed Masterbatch NOBS-70

| Composition | 70% N-oxydiethylene-2-benzothiazyl sulfenamide 30% Ethylene-propylene rubber carrier and surface active dispersing agent |

| Specification | 20kg/box |

| Appearance | White to beige granules |

Technical Feature

The predispersed masterbatch NOBS-70 extends the scorch time of the rubber materials and makes the vulcanization safer. It can be used separately as the primary accelerator in low-sulfur vulcanization. Or it can be used together with dithiocarbamates or thiurams accelerators. The scorch time of the rubber is greatly reduced and the obtained vulcanized rubber has excellent heat aging resistance and good compression set.

When the pre-dispersed NOBS-70 and thiuram TMTM-70 are used together, the vulcanization time is significantly shortened and there is good anti-scorch effect as well as high degree of crosslinking. In low-sulfur rubber materials as well as rubber materials containing thiols accelerators, the pre-dispersed NOBS-70 can delay scorch.

Processing Advantage

The powdery NOBS is usually easy to fly and adhere to devices. It is not easy to disperse evenly during mixing. But the pre-dispersed NOBS-70 is easy for mixing. It will not agglomerate under normal storage conditions. With good flowability, there is no dust flying and no material loss caused. The optimal activity of the effective ingredient, NOBS, is ensured due to the quick blending into various rubbers anduniform dispersion. It is recommended to add the product in the late stage of mixing.

Application

Tire treads, carcasses, cables, rubber tubes rubber belts, conveyor belts, rubber shoes, and other rubber products

Packaging

Calcium plastic box, 20kg/box

Storage

Cool, dry places; 2 years in original closed container

Related Names

NOBS Rubber Additive Supplier | Gasket Production | Rubber Mounts Making

Links:https://globefindpro.com/products/84002.html

-

Rubber Predispersed Masterbatch IS

Rubber Predispersed Masterbatch IS

-

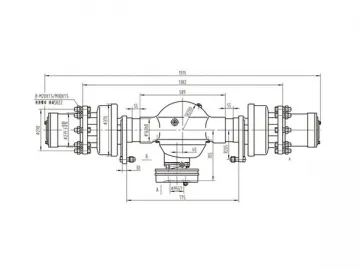

5T/6T Forklift Truck Axle

5T/6T Forklift Truck Axle

-

Rubber Predispersed Masterbatch ZnO

Rubber Predispersed Masterbatch ZnO

-

Rubber Predispersed Masterbatch S

Rubber Predispersed Masterbatch S

-

SBG200 HDPE/PP Double Wall Corrugated Pipe Extrusion Line

SBG200 HDPE/PP Double Wall Corrugated Pipe Extrusion Line

-

Plastic Pipe Cutting Machine

Plastic Pipe Cutting Machine

-

Rubber Predispersed Masterbatch TMTD

Rubber Predispersed Masterbatch TMTD

-

Paraquat

Paraquat

-

PE Steel Strip Reinforced Spiral Pipe Extrusion Line

PE Steel Strip Reinforced Spiral Pipe Extrusion Line

-

Chlorpyrifos

Chlorpyrifos

-

SBG315 UPVC Double Wall Corrugated Pipe Extrusion Line

SBG315 UPVC Double Wall Corrugated Pipe Extrusion Line

-

PEX/Al/PEX Aluminum Composite Pipe Extrusion Line

PEX/Al/PEX Aluminum Composite Pipe Extrusion Line