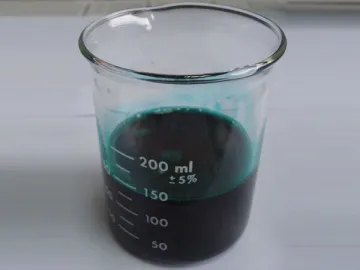

Rubber Predispersed Masterbatch IS

| Name | IS90-65 | IS60-75 | IS60-80 |

| Composition | 90% Sulfur (65% insoluble sulfur and 35% soluble sulfur) 25% Ethylene-propylene rubber carrier and surface active dispersing agent | 75% Sulfur (60% insoluble sulfur and 40%soluble sulfur) 25% Ethylene-propylene rubber carrier and surface active dispersing agent | 80% Sulfur (60% insoluble sulfur and 40%soluble sulfur) 20% Ethylene-propylene rubber carrier and surface active dispersing agent |

| Specification | 25kg/box | 25kg/box | 25kg/box |

| Appearance | Yellow granules | Yellow granules | Yellow granules |

| Density | 1.40 ± 0.05 g/cm3 (25℃) | 1.40 ± 0.05 g/cm3 (25℃) | 1.48 ± 0.05 g/cm3 (25℃) |

| Mooney viscosity(100℃) | 18±5 | 18±5 | 20±5 |

Technical Feature

The predispersed masterbatch IS 90-65 contains 90% sulfur which is composed of 65% insoluble sulfur (insoluble in CS2) and 40% soluble sulfur. It serves as the vulcanizing agent for all natural rubbers and diene rubbers. Compared with common sulfur, the outstanding features of the pre-dispersed IS are no blooming and no shifting to other layers. Therefore, it is widely used in the manufacture of tires, conveyor belts, rubber shoes, and other rubber products that require no blooming, multi-layer vulcanization, and high adhesive property.

Processing Advantage

Generally, powdery insoluble sulfur is easy to fly and adhere to devices. It is difficult to disperse evenly during mixing. However, the predispersed IS solves these problems. It will not agglomerate under normal storage conditions. It has good flowability. There is no powder flying during mixing. Quick blending into various rubbers and uniform dispersion ensure optimal activity of the effective ingredient.

Application

Tires, conveyor belts, retreaded tires, rubber tubes, seals, rubber rollers, etc.

Packaging

Calcium plastic box lined with PE bag, 25kg/box

Storage

Cool, dry place; 24 months in original closed container

Related Names

Automotive Industry Additive Provider | Sealing Part Manufacturing | Rubber Chemical

Links:https://globefindpro.com/products/84003.html

-

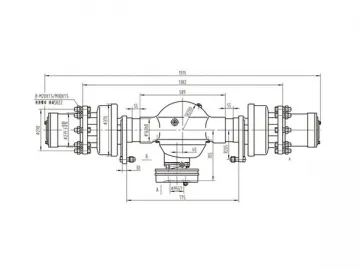

5T/6T Forklift Truck Axle

5T/6T Forklift Truck Axle

-

Rubber Predispersed Masterbatch ZnO

Rubber Predispersed Masterbatch ZnO

-

Rubber Predispersed Masterbatch S

Rubber Predispersed Masterbatch S

-

SBG200 HDPE/PP Double Wall Corrugated Pipe Extrusion Line

SBG200 HDPE/PP Double Wall Corrugated Pipe Extrusion Line

-

Plastic Pipe Cutting Machine

Plastic Pipe Cutting Machine

-

SBG250 UPVC Double Wall Corrugated Pipe Extrusion Line

SBG250 UPVC Double Wall Corrugated Pipe Extrusion Line

-

Rubber Predispersed Masterbatch NOBS-70

Rubber Predispersed Masterbatch NOBS-70

-

Rubber Predispersed Masterbatch TMTD

Rubber Predispersed Masterbatch TMTD

-

Paraquat

Paraquat

-

PE Steel Strip Reinforced Spiral Pipe Extrusion Line

PE Steel Strip Reinforced Spiral Pipe Extrusion Line

-

Chlorpyrifos

Chlorpyrifos

-

SBG315 UPVC Double Wall Corrugated Pipe Extrusion Line

SBG315 UPVC Double Wall Corrugated Pipe Extrusion Line