Rubber Predispersed Masterbatch TMTD

| Name | TMTD-70 | TMTD-70 (plate) | TMTM-75 |

| Composition | 70% Tetramethyl thiuram disulfide 30% Ethylene-propylene rubber carrier and surface active dispersing agent | 70% Tetramethyl thiuram disulfide 30% Ethylene-propylene rubber carrier and surface active dispersing agent | 75% Tetramethyl thiuram disulfide 25% Ethylene-propylene rubber carrier and surface active dispersing agent |

| Specification | 20kg/box | 20kg/box | 20kg/box |

| Appearance | White granules | White | White granules |

| Density | 1.15 ± 0.05g / cm3 (25℃) | 1.15 ± 0.05g / cm3 (25℃) | 1.13 ± 0.05g / cm3 (25℃) |

| Mooney viscosity (100℃) | 20±5 | 20±5 | 30±5 |

Technical Feature

Used in the vulcanization of natural rubbers and synthetic rubbers, the predispersed masterbatch TMTD speeds up the vulcanization and improves the scorch safety. If thiols or sulphenamides accelerators are added, the vulcanization will be delayed. But the degree of crosslinking is almost not affected; only the scorch speed is reduced and the total vulcanization time is extended. Aldehyde amines, guanidines, and other alkalineaccelerators can activate the pre-dispersed TMTD. When used together with sulfur, the pre-dispersed TMTD serves as the primary accelerator. When used with thiazoles accelerators, it functions as the secondary accelerator. It is also used as the vulcanizing agent in the sulfur-free vulcanization. Sulfur-free or low-sulfur vulcanization can endow the vulcanized rubber good thermal aging resistance.

Processing Advantage

Typically, the powdery TMTD is liable to fly around and adhere to the devices. It is difficult to disperse evenly during mixing and the vulcanized rubber is easy to bloom. The predispersed masterbatch TMTD avoids these problems. It has good flowability, so there is no powder flying during mixing. It is easy to blend into various rubbers and disperse evenly, thus ensuring the optimum activity of the effective ingredient. Under normal storage conditions, the pre-dispersed TMTD will not agglomerate. It is suggested to add this material in the late stage of mixing.

Application

Heat-resistant industrial products, tires, cable jacket and insulation, hard rubber

Packaging

Calcium plastic box lined with PE bag, 20kg/box

Storage

Cool, dry places; 12 months in original closed container

Related Names

Additive to Improve Strength | Cured Profile Making Additive | Door and Window Profile Production

Links:https://globefindpro.com/products/84001.html

-

Rubber Predispersed Masterbatch NOBS-70

Rubber Predispersed Masterbatch NOBS-70

-

Rubber Predispersed Masterbatch IS

Rubber Predispersed Masterbatch IS

-

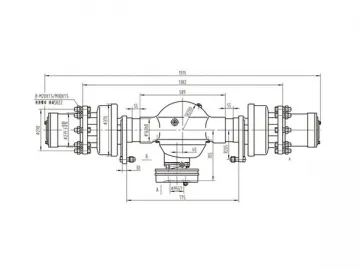

5T/6T Forklift Truck Axle

5T/6T Forklift Truck Axle

-

Rubber Predispersed Masterbatch ZnO

Rubber Predispersed Masterbatch ZnO

-

Rubber Predispersed Masterbatch S

Rubber Predispersed Masterbatch S

-

SBG200 HDPE/PP Double Wall Corrugated Pipe Extrusion Line

SBG200 HDPE/PP Double Wall Corrugated Pipe Extrusion Line

-

Paraquat

Paraquat

-

PE Steel Strip Reinforced Spiral Pipe Extrusion Line

PE Steel Strip Reinforced Spiral Pipe Extrusion Line

-

Chlorpyrifos

Chlorpyrifos

-

SBG315 UPVC Double Wall Corrugated Pipe Extrusion Line

SBG315 UPVC Double Wall Corrugated Pipe Extrusion Line

-

PEX/Al/PEX Aluminum Composite Pipe Extrusion Line

PEX/Al/PEX Aluminum Composite Pipe Extrusion Line

-

1.8% Abamectin and 3.2% Acetamiprid EC

1.8% Abamectin and 3.2% Acetamiprid EC