SBG200 HDPE/PP Double Wall Corrugated Pipe Extrusion Line

Our SBG200 HDPE/PP double wall corrugated pipe extrusion line is designed and developed by our company in accordance with the need of plastic market. It is the latest research achievement in the plastic extrusion molding field, by absorbing progressive technology from foreign companies. This line is suitable for high-speed extrusion of HDPE, LDPE, PP, and other raw materials. The inside diameter of available pipe varies from 63mm to 200mm.

This double wall corrugated pipe extrusion line adopts the direct extrusion molding technology of PE high-speed and high-efficiency single-screw extruder. Additionally, the extrusion head is designed with special structure. Therefore, the molding process is quite stable. The corrugator has horizontal structure and chain transmission. The mould block made of aluminum alloy is equipped with open type water-cooling system and advanced self-lubricating system, which can significantly increase the production speed. By adoption of the specialized PLC control system from Germany Siemens Company, the whole line can be operated easily and reliably with high degree of automation.

Main Specifications

| Components | Model | Overall Dimension(Length ×Width × Height) mm | Total Power(kW) | Weight(kg) |

| Extruder(Co-extrusion) | SJ75 ×30 SJ55 ×30 | 3850 ×480 ×1240 3000 ×350 ×1170 | 110 (max.) 61 (max.) | 1800 800 |

| Extrusion (Single Extrusion) | SJ90 ×30 | 3400 ×560 ×3000 | 110 (max.) | 2200 |

| Mould Blocks(Inside Diameter) | PE63/PE75/PE90/PE110 | 2000×Φ300 | 16 (max.) | 150-180 |

| PE125/PE145/PE160/PE200 | 2000 ×Φ326 | 400-450 | ||

| Corrugator | SBCJ200 | 3500 ×1750 ×1730 | 4 (max.) | 3500 |

| Cutter | QG200 | 2715 ×1000 ×1720 | 2.2 | 800 |

| UnloadingBracket | JGJ200 | 5000 ×800 ×1000 | 150 |

Samples

Related Names

Eco-friendly Pipe Making Machine Manufacturer | High Strength Water Supply Pipe | Custom Plastic Pipe

Links:https://globefindpro.com/products/84007.html

-

Plastic Pipe Cutting Machine

Plastic Pipe Cutting Machine

-

SBG250 UPVC Double Wall Corrugated Pipe Extrusion Line

SBG250 UPVC Double Wall Corrugated Pipe Extrusion Line

-

Insulated Water Supply Corrugated Pipe Extrusion Line

Insulated Water Supply Corrugated Pipe Extrusion Line

-

Single Screw Extruder

Single Screw Extruder

-

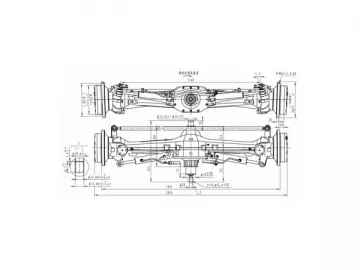

Construction Machinery Rim

Construction Machinery Rim

-

120 Horsepower Four-wheel Drive Tractor Axles

120 Horsepower Four-wheel Drive Tractor Axles

-

Rubber Predispersed Masterbatch S

Rubber Predispersed Masterbatch S

-

Rubber Predispersed Masterbatch ZnO

Rubber Predispersed Masterbatch ZnO

-

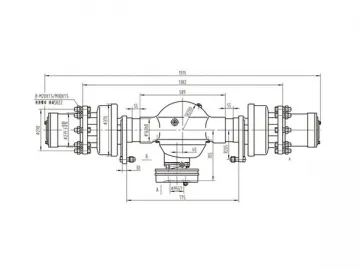

5T/6T Forklift Truck Axle

5T/6T Forklift Truck Axle

-

Rubber Predispersed Masterbatch IS

Rubber Predispersed Masterbatch IS

-

Rubber Predispersed Masterbatch NOBS-70

Rubber Predispersed Masterbatch NOBS-70

-

Rubber Predispersed Masterbatch TMTD

Rubber Predispersed Masterbatch TMTD