PVC Water Supply Pipe Extrusion Line

This PVC water supply pipe extrusion line mainly is specially designed for manufacturing PVC water supply and drainage pipes. It mainly consists of the conical twin-screw extruder, PVC pipe moulds, vacuum sizing tank, water spraying and cooling tank, haul-off machine, cutting machine, and overturning bracket.

The extruder comes with the forced dosing system, automatic temperature control system, vacuum pumping system, and automatic speed regulating system. This structure can not only ensure the plasticizing stability as well as the precise control for material processing temperature, but also provide the whole production line with high efficiency. By employing the PLC control system from Germany Siemens Company, our PVC water supply pipe extrusion line can be characterized by intelligent control, convenient operation, and stable action.

Detailed Data

| Model | Pipe Diameter (mm) | Model of Extruder | Production Speed (m/min) | Maximum Output (kg/h) | Total Power (kW) | Overall Dimension L× W× H |

| SJPGZ-50 | Ø20-Ø50 | SJSZ-51/105 | 1-12 | 150 | 65 | 32×1.8×2m |

| SJPGZ-250 | Ø50-Ø250 | SJSZ-65/132 | 0.5-5 | 300 | 100 | 36×2×2m |

| SJPGZ-315 | Ø110-Ø315 | SJSZ-80/156 | 1-3.6 | 420 | 145 | 38×2×2m |

| SJPGZ-400 | Ø200-Ø400 | SJSZ-80/156 | 0.2-2 | 420 | 150 | 42×2.5×2.5m |

| SJPGZ-630 | Ø315-Ø630 | SJSZ--92/188 | 0.08-0.8 | 750 | 245 | 48×2.5×2.5m |

Samples

Related Names

Plastic Water Pipeline Extruder Manufacturer | Industrial PVC Piping System | Tubing Making Machine

Links:https://globefindpro.com/products/84025.html

-

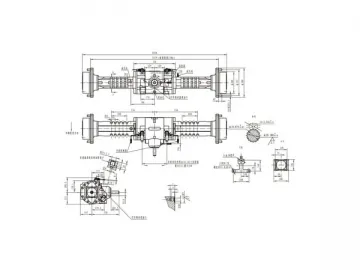

2.5T Drive Axle

2.5T Drive Axle

-

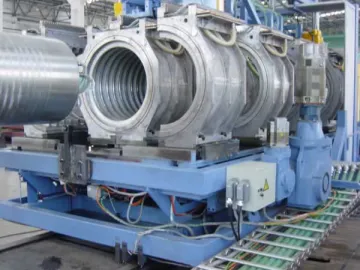

HDPE/PP Single Wall Corrugated Cable Protective Pipe Extrusion Line

HDPE/PP Single Wall Corrugated Cable Protective Pipe Extrusion Line

-

3T Forklift Steering Axle

3T Forklift Steering Axle

-

SBG1000 UPVC Double Wall Corrugated Pipe Extrusion Line

SBG1000 UPVC Double Wall Corrugated Pipe Extrusion Line

-

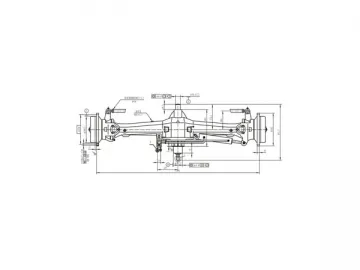

80-90 Horsepower Tractor Front Axle

80-90 Horsepower Tractor Front Axle

-

Road Roller Drive Axle

Road Roller Drive Axle

-

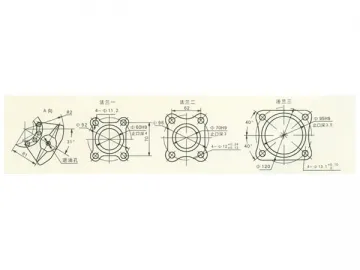

RT Base

RT Base

-

7T Forklift Truck Axle

7T Forklift Truck Axle

-

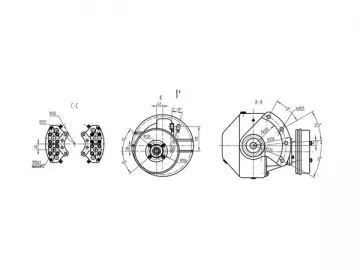

Caliper Disc Brake

Caliper Disc Brake

-

Wet Brake Drive Axle

Wet Brake Drive Axle

-

WZD75 Loader-Digger Drive Axle

WZD75 Loader-Digger Drive Axle

-

PE Communication Pipe

PE Communication Pipe