SBG1000 UPVC Double Wall Corrugated Pipe Extrusion Line

Our SBG1000 UPVC double wall corrugated pipe extrusion line serves to manufacture the pipe with its outside diameter scope from 500mm to 1000mm. It is our latest research achievement in the plastic extrusion molding industry, by absorbing advanced technology from foreign competitors. Then, our company can fully meet the need of plastic market.

This UPVC double wall corrugated pipe extrusion line is designed with one PVC conical twin-screw extruder. The superior alloy-steel composite extrusion head is processed by chrome-plating and polishing treatment. The molding machine comes with horizontal structure, shuttle transmission, vacuum forming system, as well as the advanced self-lubricating system.

The aluminum alloy forming mould block is driven by Germany Siemens servo motor. Also, our dual-blade rotary cutting machine is controlled by the professional PLC program from Siemens, thus making the operation simple and agile. Furthermore, this entire UPVC double wall corrugated pipe extrusion line adopts the perfect PLC control system from Germany Siemens, as well as the 15" ultra-large colored touch screen, thereby providing high degree of automation, high reliability, and easy operation. With remote communication function, our line can realize the remote fault diagnosis and troubleshooting.

Main Technical Parameters

| Components | Model | Overall Dimension(Length ×Width × Height) mm | Total Power (kW) | Weight(kg) |

| Extruder | SJSZ95 | 7000×1830×2500 | 230 (max.) | 10000 |

| Mould Blocks | SBZG500(Inside Diameter) | 2900×Φ700 | 120 (max.) | 4100 |

| SBZG600(Inside Diameter) | 4200 | |||

| SBZG630(Outside Diameter) | 4200 | |||

| SBZG800(Outside Diameter) | 3200×Φ1195 | 6800 | ||

| SBZG800(Inside Diameter) | 7000 | |||

| Corrugator | SBCJ1000 | 7500×2100×2400 | 100 (max.) | 20000 |

| Cutter | QG9030 | 4252×2100×2400 | 7.5 | 4000 |

| Belling Machine | SGK1000 | 8500×3800×3300 | 45 | 8000 |

Related Names

Recycling Pipe Making Device Manufacturer | Agricultural Irrigation Pipe | Plastic Processing Machine

Links:https://globefindpro.com/products/84029.html

-

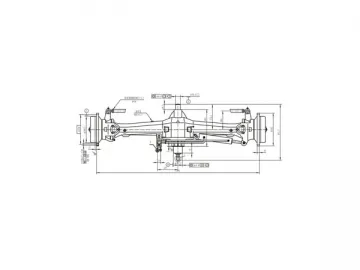

80-90 Horsepower Tractor Front Axle

80-90 Horsepower Tractor Front Axle

-

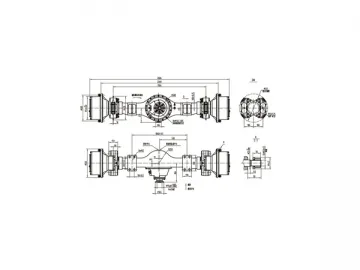

Road Roller Drive Axle

Road Roller Drive Axle

-

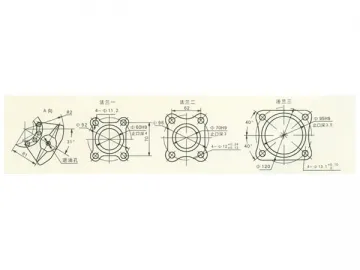

3T/6T/8T Drive Axle

3T/6T/8T Drive Axle

-

Rubber Accelerator ZDEC/EZ

Rubber Accelerator ZDEC/EZ

-

Rubber Predispersed Masterbatch ETU-75

Rubber Predispersed Masterbatch ETU-75

-

Rubber Predispersed Masterbatch CBS

Rubber Predispersed Masterbatch CBS

-

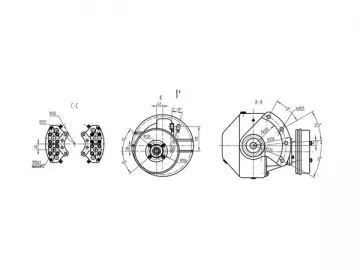

3T Forklift Steering Axle

3T Forklift Steering Axle

-

HDPE/PP Single Wall Corrugated Cable Protective Pipe Extrusion Line

HDPE/PP Single Wall Corrugated Cable Protective Pipe Extrusion Line

-

2.5T Drive Axle

2.5T Drive Axle

-

PVC Water Supply Pipe Extrusion Line

PVC Water Supply Pipe Extrusion Line

-

RT Base

RT Base

-

7T Forklift Truck Axle

7T Forklift Truck Axle