Rubber Antiscorching Agent CTP(PVI)

1. Chemical Name: N-Cyclohexylthio Phthalimide

Names of similar products at home and abroad: CTP, PVI

2. Molecular Formula: C14H15O2NS

3. Structural Formula

Molecular weight: 261.33

CAS registry number: 17796-82-6

4. Technical Requirements

a. Some indicators of our normally produced products are listed below

| Powder | Oil treated powder | Granule | Detection method | |

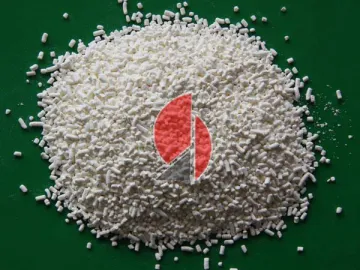

| Appearance (visual observation) | White or light yellow crystalline powder | White or light yellow crystalline powder | White or light yellow granule | Q/SHY003-2008:4.1 |

| Initial melting point ℃ ≥ | 89.0 | 89.0 | 89.0 | Q/SHY003-2008:4.2 |

| Heating loss % ≤ | 0.30 | 0.40 | 0.30 | Q/SHY003-2008:4.3 |

| Ash % ≤ | 0.10 | 0.10 | 0.10 | Q/SHY003-2008:4.4 |

| Substance insoluble in toluene % ≤ | 0.50 | 0.50 | 0.50 | Q/SHY003-2008:4.5 |

| Oil content % | - | 1.0-2.0 | - | Q/FX001-2008 |

| Average particle strength N | - | - | 0.3-1.0 | Q/FX002-2008 |

| Max. particle strength N | - | - | 1.5 | Q/FX002-2008 |

| Chalking rate (20 mesh) % ≤ | - | - | 3.0 | Q/FX004-2008 |

| Executive standard | Q/SHY003-2008 | |||

b. Customers' special requirements on the product can be met.

c. Foreign matters are completely prevented from mixing with the product.

d. Packaging quality meets the requirements of our company or the customers.

5. Property

CTP is soluble in acetone, benzene, toluene, diethyl ether and ethyl acetate as well as warm carbon tetrachloride, ethanol and heptane. It is slightly soluble in gasoline and insoluble in kerosene and water.

6. Use

CTP can effectively prevent the natural rubber and synthetic rubber from scorching during processing, thus enabling the calendar and extruder to run at high speed and high temperature and improving the production capacity of vulcanizing machine. It can also prevent natural vulcanization of the rubber materials during storage, improving the storage stability. In addition, this product plays a regenerative restoration role for the rubber materials which have been subjected to high heat or which have the risk of scorch.

7. Packaging

Woven bag lined with plastic bag, orkraft paper bag; 20 or 25 kg/bag; or as per customer requirements

Related Names

Scorch Retarder Manufacturer | Rubber Scorching Prevention | Vulcanization Activator

Links:https://globefindpro.com/products/84042.html

-

Digital Luggage Scale

Digital Luggage Scale

-

Rubber Accelerator TBBS/NS

Rubber Accelerator TBBS/NS

-

Rubber Accelerator CBS/CZ

Rubber Accelerator CBS/CZ

-

10

10

-

Rubber Predispersed Masterbatch MBTS

Rubber Predispersed Masterbatch MBTS

-

Multifunction Kitchen Scale

Multifunction Kitchen Scale

-

Digital Food Scale

Digital Food Scale

-

Rubber Accelerator DPG/D

Rubber Accelerator DPG/D

-

Rubber Predispersed Masterbatch TMTM

Rubber Predispersed Masterbatch TMTM

-

Rubber Predispersed Masterbatch BZ-75

Rubber Predispersed Masterbatch BZ-75

-

Rubber Predispersed Masterbatch DPTT-75

Rubber Predispersed Masterbatch DPTT-75

-

Rubber Predispersed Masterbatch CBS

Rubber Predispersed Masterbatch CBS