Rubber Predispersed Masterbatch MBTS

| Name | MBTS-50 | MBTS-70 | MBTS-75 |

| Composition | 50% Dibenzothiazyl disulfide 50% Ethylene-propylene rubber carrier and surface active dispersing agent | 70% Dibenzothiazyl disulfide 30% Ethylene-propylene rubber carrier and surface active dispersing agent | 75% Dibenzothiazyl disulfide 25% Ethylene-propylene rubber carrier and surface active dispersing agent |

| Specification | 20kg/box | 20kg/box | 20kg/box |

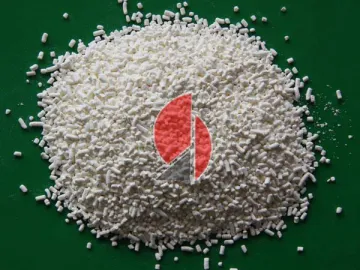

| Appearance | Beige granules | Beige granules | Beige granules |

| Density | 1.20 ± 0.05 g/cm3 (25℃) | 1.20 ± 0.05 g/cm3 (25℃) | 1.26 ± 0.05 g/cm3 (25℃) |

| Mooney viscosity (100℃) | 20±5 | 22±5 | 40±5 |

Technical Feature

The predispersed masterbatch MBTS is a universal quasi-high-speed accelerator with good processing safety. It can be used alone or with other accelerators. It can be activated by thiurams, dithiocarbamates and aldehyde amines accelerators. When used together with activated dithiocarbamates accelerators, it can prevent scorch. In the processing and vulcanization of CR materials, the pre-dispersed MBTS has delay effect. The vulcanized rubber obtained by using the pre-dispersed MBTS has goodheat aging resistance.

Processing

Generally, the powdery MBTS is easy to fly and stick on the device, and it is not easy to disperse evenly during mixing. Nevertheless, the pre-dispersed MBTS is easy to mix. It has good flowability and there is no dust flying, so no material loss is resulted in. It will not agglomerate under normal storage conditions. It blends easily into various rubbers and disperses evenly, thus ensuring optimal activity of the effective ingredient, MBTS. It is suggested to add this product in the late stage of mixing.

Application

Heat-resistant industrial products, cable sheathing and insulation layer, hard rubber

Packaging

Calcium plastic box lined with polyethylene bag, 20kg/box

Storage

Stored in a cool, dry place; Sealed storage for 24 months with original packaging

Related Names

Rubber Accelerator Manufacturer | Rubber Property Improvement | Granule Additive

Links:https://globefindpro.com/products/84048.html

-

Multifunction Kitchen Scale

Multifunction Kitchen Scale

-

Rubber Accelerator TMTD/TT

Rubber Accelerator TMTD/TT

-

Rubber Accelerator TMTM/TS

Rubber Accelerator TMTM/TS

-

Rubber Accelerator MBT/M

Rubber Accelerator MBT/M

-

Rubber Accelerator ZDBC/BZ

Rubber Accelerator ZDBC/BZ

-

Rubber Predispersed Masterbatch BZ-80

Rubber Predispersed Masterbatch BZ-80

-

10

10

-

Rubber Accelerator CBS/CZ

Rubber Accelerator CBS/CZ

-

Rubber Accelerator TBBS/NS

Rubber Accelerator TBBS/NS

-

Digital Luggage Scale

Digital Luggage Scale

-

Rubber Antiscorching Agent CTP(PVI)

Rubber Antiscorching Agent CTP(PVI)

-

Digital Food Scale

Digital Food Scale