Rubber Predispersed Masterbatch DPTT-75

1. Chemical Composition

Bis (pentamethylene) thiuram tetrasulfide and rubber

2. Physical Properties

Light yellow granules, tasteless and non-toxic; soluble in chloroform, benzene, acetone, and carbon disulfide; slightly soluble in gasoline and carbon tetrachloride; insoluble in water and dilute alkali

3. Specification

| Appearance | Light yellow granules |

| DPTT content | 75% |

| Mooney viscosity (100℃) | 25±5 |

| Specific gravity | 1.22±0.05 |

4. Application

The predispersed masterbatch DPTT-75 is mainly used in the manufacture of heat-resistant products, cables, etc. It can be used as the secondary accelerator for natural rubber, synthetic rubber, and latex. Since it can decompose free sulfur when heated, it can serve as the vulcanizing agent. When used as the vulcanizing agent, it is safe to handle at the operating temperature and the obtained vulcanized rubber has excellent resistance to heat and aging.

This product can also be used as the primary accelerator for hypalon, styrene-butadiene rubber, and butyl rubber. When used together with thiazole accelerators, it is particularly suitable for nitrile rubber and the vulcanized rubber has outstanding compression deformation and heat resistance.

5. Packaging and Storage

a. Packaging

Calcium plastic box lined with plastic bag, 20kg/box, or as per customer requirement

b. Seal storage

Store the product in ventilated, cool places. Avoid direct sunlight.

c. Storage period

At least 12 months under normal storage conditions

Related Names

Molded Rubber Additive for Sale | Rubber Cover Production | Colloidal Particle

Links:https://globefindpro.com/products/84036.html

-

Rubber Predispersed Masterbatch BZ-75

Rubber Predispersed Masterbatch BZ-75

-

Rubber Predispersed Masterbatch TMTM

Rubber Predispersed Masterbatch TMTM

-

Rubber Accelerator DPG/D

Rubber Accelerator DPG/D

-

Digital Food Scale

Digital Food Scale

-

Rubber Antiscorching Agent CTP(PVI)

Rubber Antiscorching Agent CTP(PVI)

-

Digital Luggage Scale

Digital Luggage Scale

-

Rubber Predispersed Masterbatch CBS

Rubber Predispersed Masterbatch CBS

-

Rubber Predispersed Masterbatch ETU-75

Rubber Predispersed Masterbatch ETU-75

-

Rubber Accelerator ZDEC/EZ

Rubber Accelerator ZDEC/EZ

-

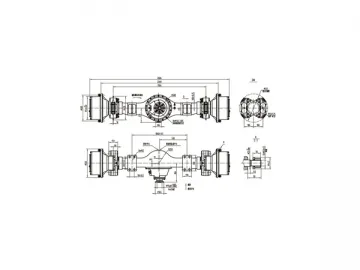

3T/6T/8T Drive Axle

3T/6T/8T Drive Axle

-

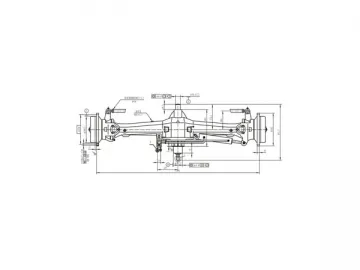

Road Roller Drive Axle

Road Roller Drive Axle

-

80-90 Horsepower Tractor Front Axle

80-90 Horsepower Tractor Front Axle