Perforated Metal

A. Selection of Metal Board

When you select the plank stuff of the perforated metal plate, you'd better consider the two aspects of actual application demand and product cost both. For example, if you want to reduce the thickness of the board, then the preferable material is alloy whose price is a little higher. The hardness and the strength of the board decide the size and arrangement mode of the holes directly. Meanwhile, you should know that the commonly used board is acceptable more easily than the material with special requirements.

The sheet material that we can provide covers stainless steel type, carbon steel type, zinc type, galvanized type, aluminum type, brass type, copper type, plywood type, fiberboard type, rubber type, paper board type, wood type, aluminum magnesium alloy type, nickel type, PVC type and various kinds of synthetics.

B. Types and Detailed Parameters of Punched Holes

a. Types

The holes can be punched with many kinds of shapes like round type, square type, oblong type, triangular type, scales type, diamond type, oval type, hexagonal type and long strip type.

b. Diameter of Hole

Generally speaking, the hole diameter of the perforated metal sheet should be greater than or equal to the thickness of the sheet material, namely meeting the minimum aperture principle. The closer the hole diameter and the thickness are, the greater the processing difficulty is. Then, the processing cost is higher accordingly. With regard to some material, the hole can be processed with the diameter less than the thickness of the plank stuff. The minimum hole diameter that we can process can be as small as 0.08mm. If customers have some special requirements, our experienced molding engineer can meet the requirements with the reasonable satisfying price as much as possible.

c. Pitch of Holes

The pitch of holes is the distance from the center of a hole to the center of the other adjacent hole. It is one way for expressing the spacing of the holes. The other way is the percentage of open area. The substantial meaning of the two ways is the same. So, you just need to choose one way to fix.

C. Specification of Sheet Material

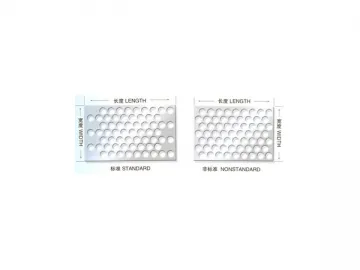

a. The Arrangement of Holes (see figure below)

We can process miscellaneous difficult patterns and designs of holes for the perforated metal plate. In spite of the additional processing fees for the specially required hole patterns and designs, the price for processing ordinary hole patterns is rather reasonable and attractive.

1. 60° Staggered Arrangement

The 60° plum arrangement is the most popular kind for the natural high strength, wide percentage of open area as well as attractive appearance.

2. 45° Staggered Arrangement

Compared with the former kind, the 45° plum arrangement provides people with another choice.

3. Straight Row

The another arrangement way for round hole is straight row. This kind of arrangement also allows for a variety of hole pattern and percentage of open area. The downside is that it has the worst pressure resistance in the round hole arrangement series.

4. Square Slot

Relative to round hole, the square slot can lead to greater percentage of open area but comparatively lower pressure resistance. So, the perforated metal plate with square slot is more appropriate for the occasions with the high requirements on the visibility of products. It is widely founded for use for the decorative desk of the store and protective cover of the machine.

5. Oblong Hole

The product with staggered oblong hole is often used for solid screening.

6. Oblong Hole (Straight Row)

The perforated metal sheet with oblong hole of straight row is mainly employed for vibration screening and filtration.

7. Hexagonal Hole

The hexagonal hole can enhance the percentage of open area to the maximum extent.

b. Percentage of Open Area

Apparently, the percentage of open area is related to the hole diameter and hole pattern. It is the ratio of open area to the total area of the board, which is expressed with percentage. It's worth noting that the pressure of the punching equipment can lead to the deformation of the sheet material. The larger the percentage of open area is, the more obvious the deformation is. The deformation of the perforated metal plate with no margin for four corners is particularly serious. The deformation can be overcome through processing by our special machine. So, you should consider that seriously before you put forward the requirement of removing the deformation.

c. Margin

Margin is the area without being perforated on the edge of the plank stuff. The typical perforated plank stuff is processed with margin available for its long edge. If you have any requirement, you should provide the specific size of the four edges for us. By reason of the actual production, the edge of the plank stuff may be affected. If that is inappropriate with your requirement, we can supply the similar products in the condition of asking your permission first.

d. Tolerance

The perforated product is allowed to have certain tolerance in thickness, bar, percentage of open area, flatness, etc. Similar to the production process of other products, higher requirement on tolerance expends high production cost. Customers should fix the specific tolerance for us to make satisfying products. If customers have no special requirements, we would process the plank stuff in line with the standard tolerance.

Schematic Figure

Patterns

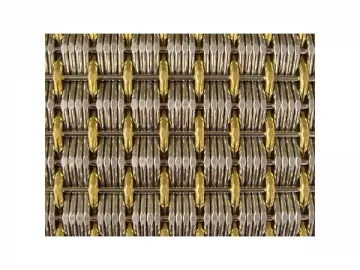

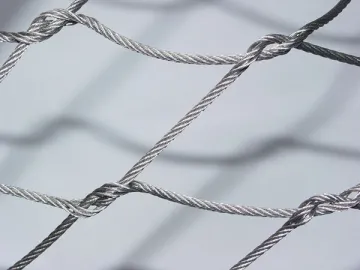

As a professional perforated metal manufacturer and supplier in China, we offer a wide array of products, including expanded metal mesh, metal conveyor belt, protective mesh, wire products, and much more.

Related Names

Bore Plate Metal | Punching Metal Sheet | Dock Metal Plate | Stiletto Metal Slat

Links:https://globefindpro.com/products/84251.html