RTM Turbo Rotor Mill

Description

The RTM turbo rotor mill is a new generation of superfine grinding equipment which has reached the international level. Being designed with advanced principle, its interval is adjustable without dismantling the whole machine. The high linear velocity enables the material to be completely smashed in an extremely short time. Consequently, the mill is suited to grind the thermal sensitive or ductile material. Coupled with the low-temperature pre-cooling system, it also can crush many kinds of polymers, such as PVA, PP, etc. By virtue of unique smashing mechanism, our machine can even be suitable for the surface modification of mineral processing, including surface modification of calcium carbonate, the dry purification of bentonite, the activated treatment of powder quartz, and more.

Working Principle

The material will be instantly pre-shattered by the blade on the rotor, after it has been added into the right box. Then, it will be scattered to the walls of the stator, and get into the smashing area which is comprised of the rotor and stator. Next, the material granules will be smashed in the high-speed air flow through colliding with each other. When smashing, heat will be inevitably generated, but it will be taken away together with the powder by the air flow. Therefore, the temperature rise is avoided. You can change the interval between the rotor and stator through adjusting the height of the gap gasket. By this way, you can obtain the desired fineness and powder output.

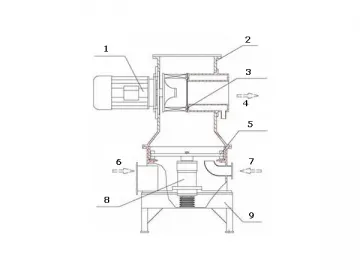

| 1. Belt Pulley2. Bearing Pedestal3. Left Box4. Middle Box5. Right Box6. Stator7. Rotor | |

| Gear Ring | Grinding Rotor |

Technical Features

1. The RTM turbo rotor mill applies the subuliform rotor and stator. Through adjusting the interval between the rotor and stator, you can control the powder fineness and output.

2. The rotor is made of the special high-intensity steel from Europe. Its linear velocity is extremely high, which ensures uniform smashing.

3. The mill offers large air volume but low temperature rise when smashing. It is perfectly suited to smash the thermoplastic or fibrous materials into the powder with uniform fineness.

4. The vertical type and horizontal type design allows convenient maintenance, operation, and cleaning.

In the actual application, the RTM turbo rotor mill can start the normal operation only when used in combination with the equipment, such as the cyclone collector, pulse dust collector, induced draft fan, etc. A silencer has been installed to the outlet of the induced draft fan, for significantly lowering the noise.

Parameter

| Item/Model | Rotor Diameter(mm) | Matched Power(kw) | Rotor Speed (Maxi. /min.) | Maxi. Air Flow(m3/h) | Fineness of Finished Product(um) | Output(kg/h) |

| RTM-300H | 300 | 18.5~22 | 7550 | 1600 | 5~250 | 30~800 |

| RTM-500H | 500 | 45 | 4700 | 2400 | 80~2000 | |

| RTM-750V | 750 | 55~75 | 3000 | 3600 | 100~300 | |

| RTM-1000V | 1000 | 90-110 | 2250 | 4800 | 200-450 | |

| RTM-1250V | 1250 | 110-132 | 1800 | 6000 | 300-6000 |

Application

Pharmaceutical Raw Materials and Chinese herbal medicine;

Low-temperature Preparation Polymer: PVA, PP, PE, PU

Rubber and Fibre

Good Gum and Sodium Alginate

Detergent and Soda Ash

Mineral Superfine Depolymerization and Surface Modification

Edible Mushroom, Chinese herbs, Plants.

Our company is an experienced turbo rotor mill manufacturer and supplier in China. We provide a variety of products, including plastic mill, spiral flow jet mill, vacuum conveyor, turbo classifier, and more.

Related Names

Turbine Rotary Mill | High Speed Crushing Equipment | Low Noise Rotor Mill

Links:https://globefindpro.com/products/84278.html

-

EP32 Cement Render Beads

EP32 Cement Render Beads

-

Laminated PVC Tarpaulin

Laminated PVC Tarpaulin

-

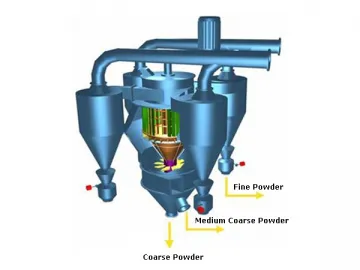

Large Capacity Powder Grading Machine

Large Capacity Powder Grading Machine

-

Coated Printable Backlit Flex Banner

Coated Printable Backlit Flex Banner

-

CSM-H Superfine Classifier Mill

CSM-H Superfine Classifier Mill

-

Steel Track (51-150mm)

Steel Track (51-150mm)

-

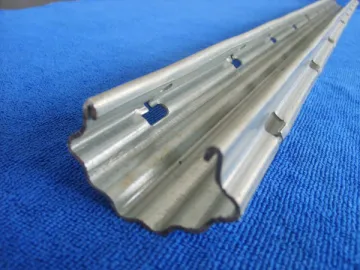

22mm Omega Furring Channel

22mm Omega Furring Channel

-

Hot Laminated Flex Frontlit Banner

Hot Laminated Flex Frontlit Banner

-

12.5 GA High-Tensile Steel Wire

12.5 GA High-Tensile Steel Wire

-

22mm Omega Cyclonic Ceiling Batten

22mm Omega Cyclonic Ceiling Batten

-

New Type Tarpaulin

New Type Tarpaulin

-

Steel Vineyard Stake

Steel Vineyard Stake