CSM-V Superfine Classifier Mill

Description

CSM-V superfine classifier mill is the same type model as the MIKROACMMILLS or domestic QWJ airflow pulverizing mill. It is mainly suitable for smashing 3.5 Mohs hardness material to obtain the superfine powder of 8 to150μm. The large cooling air flow can be applied to grind the heat sensitive material.

Working Principle

The cylindric inner cavity of the machine is divided into the upper part and lower part, separately used for ultramicro grading and grinding. The smashing system comprised of the smashing disc and abrasive disk, can crush the material into fine powder. Then, the fine powder will be graded into the type with qualified fineness and the type with unqualified fineness, by the grading system which is made of grading impeller. The qualified powder will be expelled from the discharge pipe, and gathered by the cyclone collector. And the unqualified powder will go back to the smashing area. It will be grinded until it is qualified.

The smashing disc and grading impeller are respectively driven by their own driving devices. Through the adjustable rotate speed of the grading impeller, the product fineness can be adjusted. With the screw feeder installed to the side wall of the machine, the material can be evenly fed to the smashing area. Meanwhile, the feeding amount can be realized via the rotating speed adjustment.

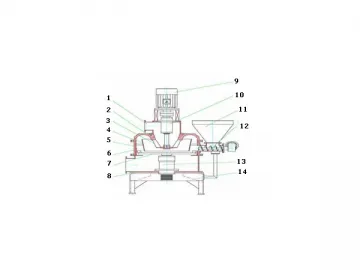

Smashing Structure Chart| 1. Outlet2. Upper Cabinet3. Grading Wheel4. Shunting Ring5. Middle Cabinet6. Gear Ring7. Rotor | 8. Lower Cabinet9. Grading Motor10. Bearing bracket for Grading11. Hopper12. Screw feeder13. Bearing Bracket for Smashing14. Base | |

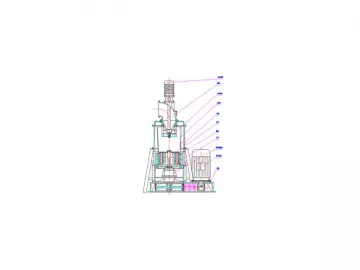

| 1. Grading Mill 2. Cyclone Collector 3. Discharging Valve 4. Pulse Filter 5. High-pressure Induced Draft Fan 6. Raw Material 7. Finished Product 1 8. Finished Product 2 | ||

Features

1. The CSM-V superfine classifier mill adopts the double-shaft design. The built-in grader rather than the traditional screen is used to adjust the fineness.

2. By means of adjusting the rotating speed of the grading impeller, the adjustment of product fineness can be realized without stopping the machine.

3. During the pulverization system, the powerful smashing airflow will have the cooling function. When grinding, the temperature rise is extremely low. Therefore, our machine is ideal for processing the heat sensitive or fibrous materials. The finished product comes with uniform fineness.

4. Both the bearing and driving belt are imported parts, thus ensuring the long lifespan of the superfine classifier mill.

5. Either grinding or grading parts are specially designed according to the material properties. The universal grinder has been upgraded to the special-purpose one, which offers higher smashing efficiency.

| Fast Split-type Main Frame | Fast Split-type Main Frame |

Parameters

| Item Model | CSM-280V | CSM-350V | CSM-510V | CSM-760V | CSM-1000V | CSM-1250V | |

| Matched Power (Kw) | Smashing Disk | 7.5 | 11-15 | 22-30 | 45-55 | 90-110 | 132-160 |

| Grading Impeller | 1.5 | 2.2 | 4-5.5 | 7.5-11 | 15 | 18.5-22 | |

| Feeder | 0.55-1 Yard | ||||||

| Rotating Speed (r/min) | Smashing Disk | 7500 | 6200 | 4200 | 2800 | 2100 | 1700 |

| Grading Impeller | 500-4500 | 500-4000 | 400-3000 | 300-2500 | 250-5000 | 200-1600 | |

| Feeder | 20-100 | ||||||

| Maxi. Processing Air Volume (m³/h) | 700 | 900 | 3000 | 5400 | 10000 | 15000 | |

| Smashing Fineness (m) | 5-300 | ||||||

| Output (kg/h) | 2-100 | 10-400 | 15-600 | 30-1200 | 60-1500 | 300-3000 | |

Application

1. Drug Materials and Antibiotics;

2. Soybean Protein, Anti-aging Plant Powder;

3. Fine Chemical Material, Organic and Inorganic Pigment, Inorganic Phosphate, Fine Additive of Toothpaste;

4. Oxidizing Material and Metal Powder; Natural or Synthetic Graphite;

5. Seasonings

It is a professional superfine classifier mill manufacturer and supplier in China. We offer a vast array of products, including rotor mill, spiral flow jet mill, vacuum conveyor, superfine powder classifier, and more.

Related Names

High Efficiency Grinding Machinery | Classifier Mill System | Variable Speed Grinding Equipment

Links:https://globefindpro.com/products/84291.html

-

Hydraulic Double-Column Stone Cutter

Hydraulic Double-Column Stone Cutter

-

Tip for Mining

Tip for Mining

-

MQL Spiral Flow Jet Mill

MQL Spiral Flow Jet Mill

-

RLM Superfine Roller Mill

RLM Superfine Roller Mill

-

CXJ Fiber Pulverizer

CXJ Fiber Pulverizer

-

MQW Fluidized Bed Jet Mill

MQW Fluidized Bed Jet Mill

-

Single Blade Hydraulic Stone Cutter

Single Blade Hydraulic Stone Cutter

-

Multi-Blade Cutting Machine

Multi-Blade Cutting Machine

-

Hot Laminated Flex Backlit Banner

Hot Laminated Flex Backlit Banner

-

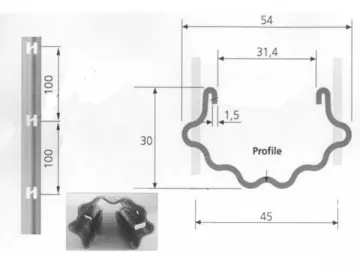

4.5mm Radius Render Corner Beads

4.5mm Radius Render Corner Beads

-

Slotted Track

Slotted Track

-

South American Style Steel Vineyard Stake

South American Style Steel Vineyard Stake