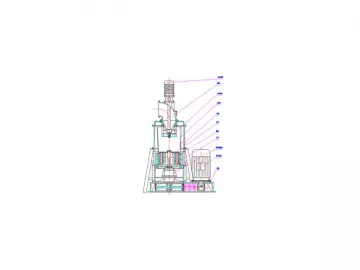

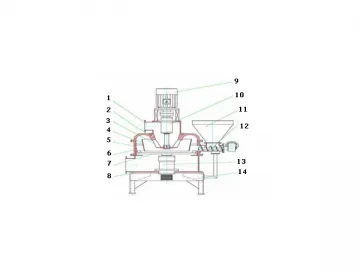

MQW Fluidized Bed Jet Mill

Working Principle

The jet mill together with the cyclone separator, dust remover, and induced draft fan, forms the entire smashing system. With the Laval nozzle, the compressed air which has been filtered and dried will be rapidly injected into the smashing cavity. In the intersection of the multi-strand high-pressure air flows, the material will be smashed via the methods like repeatedly colliding, grinding, and shearing. Under the action of the draught fan, the powder will move to the grading area along with the upcurrent. The high-speed rotational grading turbine generates the powerful centrifugal force, to separate the fine powder and coarse powder. Then, the qualified powder will get into the cyclone separator via the grading wheel, and will be collected by the dust remover. On the other side, the coarse particle will go back to the smashing area for continuous grinding.

Features

1. The MQW fluidized bed jet mill is ideal for the dry ground of the materials whose Mohs hardness is below grade 9. It is especially applicable for grinding the materials with high hardness, purity, or additional value.

2. With the built-in horizontal type grading device, the product fineness can be adjustable among the D97: 2 to 45μm. It offers good grain shape and narrow size distribution.

3. This machine is applicable for low-temperature non-media smashing, especially the heat sensitive, low melting point, or volatile materials as well as the sugary materials.

4. The smashing is complemented mainly through the collision of the materials. Unlike the machine which uses the blade or hammer for impact crushing the material, this equipment is resistant to abrasion, and can produce the powder of high purity.

5. Our machine is easy to install, disassemble, or clean. Its inner wall is smooth.

7. The whole system applies the enclosed smashing, which allows little dust or low noise generation. The clean and environmental production process is ensured.

8. Since the controlling system adopts the process control, our machine features easy operation.

| Item/Model | MQW03 | MQW06 | MQW10 | MQW20 | MQW40 | MQW60 | MQW120 | MQW160 | MQW240 |

| The fineness of Feeding Material (mm) | <3 | <3 | <3 | <3 | <3 | <3 | <3 | <3 | <3 |

| Product Fineness (D97: μm) | 2~45 | 2~45 | 2~45 | 5~45 | 5~45 | 5~45 | 5~45 | 5~45 | 5~45 |

| Production Capacity (kg/h) | 2~30 | 30~200 | 50~500 | 100~1000 | 200~2500 | 500~3500 | 800~7500 | 1000~10000 | 1500~15000 |

| Air Consumption m3/min | 3 | 6 | 10 | 20 | 40 | 60 | 120 | 160 | 240 |

| Air Pressure Mpa | 0.7~0.85 | 0.7~0.85 | 0.7~0.85 | 0.7~0.85 | 0.7~0.85 | 0.7~0.85 | 0.7~0.85 | 0.7~0.85 | 0.7~0.85 |

| Installed Power (kw) | 21.8 | 42.5 | 80 | 147 | 282 | 415 | 800 | 1100 | 1600 |

Application Case

Black and color carbon powder

Dyestuff

Abrasive powder and other mineral

Inorganic silicate

Paint coatings and additive

Micro glass bead

Plants

Natural or synthetic graphite

Hard-metal compounds and other metal powder

Ceramic glaze

As an experienced fluidized bed jet mill manufacturer and supplier in China, It provides a comprehensive range of products, including impact mill, vacuum conveyor, rotor mill, superfine powder classifier, and more.

Related Names

Fluid Energy Jet Mill | Particulate Material Grinding Equipment | Eco-friendly Jet Mill

Links:https://globefindpro.com/products/84299.html