RLM Superfine Roller Mill

Description

RLM superfine roller mill is created through combining the merits and demerits of the machines, at home and abroad. By adopting the fluid mechanics principle, the product fineness could reach 3 to 35um. This machine possesses the characteristics, including good performance, high efficiency, small occupation area, easy installation, etc.

Working Principle

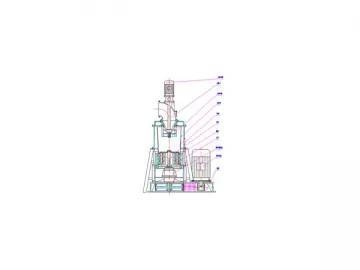

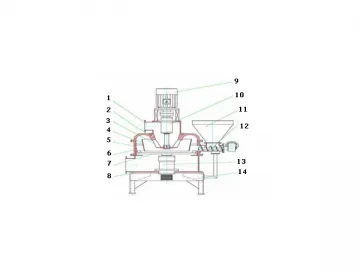

The machine is an internal grading high pressure superfine roller mill which can simultaneously complete the smashing and separating tasks. It consists of the body, base, smashing device, grading device, discharging system, transmission device, and motor. The internal structure is illustrated as the figure.

The main axle is driven by the transmission device. The upper part of the main axle is connected to the rotor frame, on which an auxiliary axis is installed. Also, this auxiliary axis is fixed onto the abrasive wheel and rotates along with the principle axis. The abrasive wheel on the auxiliary axis not only revolves around the main shaft, but also rotates around its own auxiliary axle. During the revolution and rotation, the abrasive wheel generates a powerful centrifugal force. Together with the stator, it offers the strong rolling performance. The smashed material, under the effect of the centrifugal force and rotating abrasive wheel, will get into the grinding area which is comprised of the abrasive wheel and stator. The material will be smashed under the effect of the large extrusion force and strong grinding force. Then, the power will drop to the tray which rotates with the main axle. The tray cast the powder into the circular ring between the stator and machine body. The negative pressure from the system allows the powder to get into the grading system. Through the grading wheel, the qualified powder will get into the collecting system, while the coarse powder will turn back to the smashing system for regrinding.

The grading motor drives the grading wheel to complement the powder classification task. You can get the desired finished product size via adjusting the rotational speed of the grading wheel. The higher speed of the grading wheel, the finer granularity you will obtain.

Technical Features

The RLM superfine roller mill is broadly applicable for ultrafine grinding the conventional nonflammable or non-explosive materials, such as kaolin, limestone, calcite, talc, graphite, etc. All those materials have the humidity less than 8% and the Mohs hardness of below grade 6. Our equipment is really the preferred choice for the further processing of the non-metal mineral powder.

1. Under the equivalent dynamic condition, this roller mill has the production efficiency one time more than the Raymond or jet mill. Due to the high pressure centrifugal force, the grinding force against the material will be improved by 30 to 40%.

2. It offers large output. When grinding calcium carbonate, this machine can hourly produce at least 1 ton powder with the fineness of 10um.

3. The product fineness ranges from 3 to 35um. It conforms to the fineness standard of the fluidized-bed type jet mill.

4. With the grading blade and stepless governor, the product fineness can be adjusted without stopping the machine. The fine powder can be recovered, and no environmental pollution will be generated.

Parameter

| Item/Model | RLM-1000 |

| Number of Grinding Wheel | 21 |

| Diameter of Grinding Wheel × Height (mm) | φ220×90 |

| Inner Diameter of Stator (mm) | φ770 |

| Rotational Speed of Main Engine (r/min) | 250 |

| Motor Power (kw) | 75 |

| Maxi. Fineness of Feeding Material (mm) | ≤20 |

| Fineness of Finished Product (um) | 3~35 |

| Rotate Speed of Grader (r/min) | 600~2000 |

| Grading Motor Power (kw) | 18.5 |

| Output (t/h) | 0.5~3.5 |

Application

It can be used for mineral processing, ceramic raw material, Ferro-phosphorus powder, slag, superfine coal ash, graphite, and electrode waste.

As a specialized superfine roller mill manufacturer and supplier in China, It also offers disc jet mill, rotor mill, powder mixing, drying and granulating equipment, superfine powder classifier, and much more.

Related Names

High Efficiency Rolling Mill | Micrometer Mill | Grinding Machine without Pollution

Links:https://globefindpro.com/products/84296.html

-

CXJ Fiber Pulverizer

CXJ Fiber Pulverizer

-

MQW Fluidized Bed Jet Mill

MQW Fluidized Bed Jet Mill

-

Manual Edge Cutting Machine

Manual Edge Cutting Machine

-

WDJ Turbo Mill

WDJ Turbo Mill

-

Four-Cylinder Hydraulic Stone Cutter

Four-Cylinder Hydraulic Stone Cutter

-

Edge Grinder

Edge Grinder

-

MQL Spiral Flow Jet Mill

MQL Spiral Flow Jet Mill

-

Tip for Mining

Tip for Mining

-

Hydraulic Double-Column Stone Cutter

Hydraulic Double-Column Stone Cutter

-

CSM-V Superfine Classifier Mill

CSM-V Superfine Classifier Mill

-

Single Blade Hydraulic Stone Cutter

Single Blade Hydraulic Stone Cutter

-

Multi-Blade Cutting Machine

Multi-Blade Cutting Machine