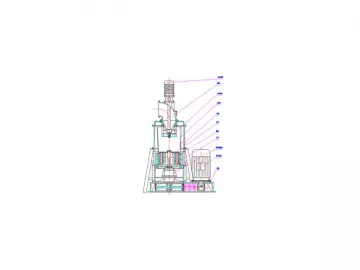

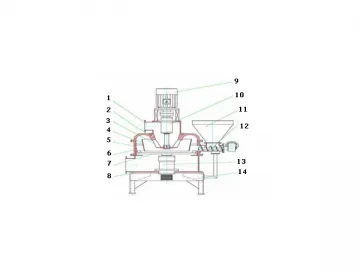

MQL Spiral Flow Jet Mill

Working Principle

The complete set of milling system is made up of the jet mill, cyclone separator, dust remover, and the induced draft fan. The compressed air after filtered and dried, will be speedily jet into the smashing cavity through the Laval nozzle. In the intersection of the multi-strand high-pressure air flows, the material is repeatedly collided, ground, sheared, and thereby smashed. Under the effect of draft force generated by the draught fan, the powder will move to the grading area along with the upcurrent. The powerful centrifugal force generated by the high-speed rotational grading turbine, will help separate the fine powder and coarse powder. Likewise, the qualified powder will get into the cyclone separator via the grading wheel, and will be collected by the dust remover. In addition, the coarse powder will drop to the smashing area for continuous grinding.

Features

1. The MQL spiral flow jet mill is suitable for the dry ground of all sorts of materials whose Mohs hardness is below 9. This machine is especially suitable for smashing the materials of high hardness, purity, or additional value.

2. With the built-in vertical type grading device, the product fineness can be adjustable among the D97: 8 to 150μm. It comes with good grain shape and narrow size distribution.

3. This machine is applicable for low-temperature non-media smashing, particularly the heat sensitive, low melting point, or volatile materials as well as the sugary materials.

4. The smashing is complemented mainly through the collision of the materials. Unlike the machine which uses the blade or hammer for impact crushing the material, this equipment is resistant to abrasion, and can produce the powder of high purity.

5. It can be connected with the multiple classifiers.

6. Our machine can be easily installed and disassembled. It is easy to clean, and the inner wall is smooth.

7. The whole system applies the enclosed smashing, which allows low dust or noise generation. The production process is clean and environmental.

8. Since the controlling system adopts the process control, our machine is easy to operate.

| Item/Specification | MQL03 | MQL06 | MQL10 | MQL20 | MQL40 | MQL60 | MQL80 |

| The Fineness of Feeding Material (mm) | <5 | <5 | <5 | <5 | <5 | <5 | <5 |

| Product Fineness d97:um | 8~150 | 8~150 | 8~150 | 8~150 | 10~150 | 10~150 | 10~150 |

| Production Capacity kg/h | 5~100 | 10~200 | 20~400 | 50~800 | 150~1500 | 300~2000 | 400~6000 |

| Air Consumption m3/min | 3 | 6 | 10 | 20 | 40 | 60 | 80 |

| Air Pressure (Mpa) | 0.7~0.85 | 0.7~0.85 | 0.7~0.85 | 0.7~0.85 | 0.7~0.85 | 0.7~0.85 | 0.7~0.85 |

| Installed Power (kw) | 26~375 | 47~68 | 68~106 | 145~184 | 276~310 | 402~427 | 520~600 |

Note: The production capacity is closely related to the material fineness, specific gravity, hardness, moisture, etc.

Application Case

Black and color carbon powder

Dyestuff

Abrasive powder and other mineral

Inorganic silicate

Paint coatings and additive

Micro glass bead

Plants

Natural or synthetic graphite

Hard-metal compounds and other metal powder

Ceramic glaze

Our company is a specialized spiral flow jet mill manufacturer and supplier in China. We offer a wide range of products, including superfine classifier mill, large capacity powder grading machine, fiber pulverizer, and more.

Related Names

Spiral Jet Mill | Air Microniser for Material Grinding | Pancake Jet Mill

Links:https://globefindpro.com/products/84295.html

-

RLM Superfine Roller Mill

RLM Superfine Roller Mill

-

CXJ Fiber Pulverizer

CXJ Fiber Pulverizer

-

MQW Fluidized Bed Jet Mill

MQW Fluidized Bed Jet Mill

-

Manual Edge Cutting Machine

Manual Edge Cutting Machine

-

WDJ Turbo Mill

WDJ Turbo Mill

-

Four-Cylinder Hydraulic Stone Cutter

Four-Cylinder Hydraulic Stone Cutter

-

Tip for Mining

Tip for Mining

-

Hydraulic Double-Column Stone Cutter

Hydraulic Double-Column Stone Cutter

-

CSM-V Superfine Classifier Mill

CSM-V Superfine Classifier Mill

-

Single Blade Hydraulic Stone Cutter

Single Blade Hydraulic Stone Cutter

-

Multi-Blade Cutting Machine

Multi-Blade Cutting Machine

-

Hot Laminated Flex Backlit Banner

Hot Laminated Flex Backlit Banner