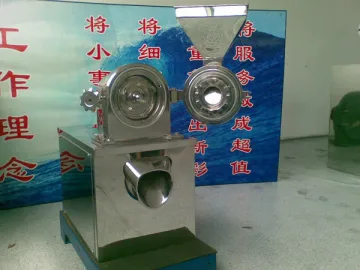

CUM Impact Mill

Description

The CUM impact mill is designed to fine grind all kinds of dry powder with the Mohs hardness of 3 to 3.5. Equipped with several grinding tools, it is applicable for all kinds of dispersive milling. Meanwhile, the smashing structure of the mill varies according to the product features. Based on the product and application, the smashing structure is divided into the pin type, turbo type, hammer type, and disc type. The pin type applies the double-rotor structure to improve the linear velocity and product fineness.

Working Principle

This machine includes the casing, door, rotor, stator, principal axis, etc. Between the casing and door, a sealing ring is installed to prevent the powder dust leakage. By adjusting the vibration feeder, the material can be quantitatively fed to the crushing cavity, thus ensuring the uniform and continuous feeding. The enclosed crushing cavity is constituted by the rotor and stator. After the material gets into the crushing cavity, it will rotate speedily along with the rotor. Meanwhile, it will move toward the outer circumferential direction under the effect of the centrifugal force. During such process, the material will violently collide with the rotor and the stator pin, by which way the powder is formed. The rotor has 3 to 4 layers of pin ring, so does the stator. Thus, the materials can be fully crushed into the powder with uniform fineness. When smashing, a large amount of air has been sucked to offer the cooling function. Moreover, the bearing is designed with a compressed air sealing device to effectively avoid the powder dust, and its life span has been thereby prolonged.

Smashing Parts

Technical Features

1. The CUM impact mill offers the fineness of D99 30µm to 800µm.

2. Many types of rotors and stators are optional, for instance, the pin type, turbo type, hammer type, etc. The grinding disc, screen cloth, and the like, are easy to operate and clean. The relative linear velocity ranges from 50 to 220m/CW.

3. According to the different product types and ideal fineness, different grinding disc will be chosen. Different machine material is used for the inert gas transmission, or 3 to10bar anti-compression and explosion-proof design is applied.

4. The machine can be utilized in the laboratory or for large-scale production.

Parameter

| Item Model | 160 | 250 | 360 | 500 | 0 | 800 | |

| Turbo Type B | Diameter of Smashing Disc (mm) | 150 | 250 | 350 | 500 | 600 | 0 |

| Maxi. Rotate Speed (r/min) | 12000 | 7500 | 5550 | 3850 | 3200 | 2800 | |

| Power(KW) | 3~4 | 5.5~7.5 | 11~15 | 18.5~30 | 30~45 | 37~75 | |

| Smashing Fineness (Mesh) | 20~325 | ||||||

| Output (kg/h) | 5~50 | 15~200 | 25~500 | 30~1200 | 50~1800 | 60~2000 | |

| Pin Type P | Diameter of Smashing Disc (mm) | 160 | 260 | 360 | 520 | 0 | 730 |

| Maxi. Rotate Speed (r/min) | 12000 | 7500 | 5550 | 3850 | 3200 | 2800 | |

| Power (KW) | 4 | 7.5 | 15~22 | 37 | 45~55 | 55~75 | |

| Smashing Fineness(Mesh) | 20~325 | ||||||

| Output(kg/h) | 20~200 | 35~1000 | 50~2000 | 75~3000 | 100~5000 | 200~10000 | |

| Disc Type M | Diameter of Smashing Disc(mm) | 350 | 550 | 750 | |||

| Maxi. Rotating Speed(r/min) | 5500 | 3500 | 2500 | ||||

| Power(KW) | 22 | 37~45 | 55~75 | ||||

| Smashing Fineness(mesh) | 20~120 | ||||||

| Output(kg/h) | 10~100 | 30~200 | 50~500 | ||||

Structure Flow Chart

Application

Pharmaceutical Raw Materials and Vitamin

White Sugar, Rice, and Starch

Pigment

Combustion Improver

Cellulose Derivative

Talcum Powder and Other cosmetics

Perfume, Salt, Glucose Powder

Zinc Oxide and Copper Powder

Detergent and Soda Ash

Wood, Tree Bark, Tree Root, Medicinal Herbs, Bone Meal

| CP-T Double-Rotor Rod Mill | Internal Structure of CP-T Double-Rotor Rod Mill |

As a China-based impact mill manufacturer and supplier, at It we also offer disc jet mill, plastic mill, superfine powder classifier, powder mixing, drying and granulating equipment, among others.

Related Names

Impact Grinding Machine | Impact Pulverizer | High Speed Beater Mill

Links:https://globefindpro.com/products/84304.html