DN Steel Jacketed Insulated Pipe

The DN steel jacketed insulated pipe consists of the steel pipe used to transport medium, anticorrosive steel tube, and the superfine glass wool filling between the inner steel pipe and the outer steel tube.

The most important feature of the protection tube for directly buried pipeline is reliable waterproofness. Also, the protection tube should possess good mechanical strength. The steel protection tube has high strength and highly reliable waterproofness. In addition, its high temperature resistance is incomparable by other outer protection tubes.

Specification of Inside Sliding Type Steel Jacketed Insulated Pipe

| Specification (mm) | Drag Reduction Layer (mm) | Inorganic Thermal Insulating Layer (mm) | Organic Thermal Insulating Layer (mm) |

| DN159/DN377 | 8 | 60 | 30 |

| DN219/DN480 | 8 | 80 | 30 |

| DN219/DN529 | 8 | 90 | 50 |

| DN273/DN529 | 8 | 80 | 30 |

| DN325/DN630 | 8 | 100 | 30 |

| DN377/DN720 | 8 | 110 | 40 |

| DN426/DN720 | 8 | 80 | 32 |

| DN529/DN820 | 10 | 80 | 30 |

| DN426/DN820 | 10 | 120 | 50 |

| DN529/DN920 | 10 | 120 | 50 |

| DN630/DN1020 | 10 | 120 | 50 |

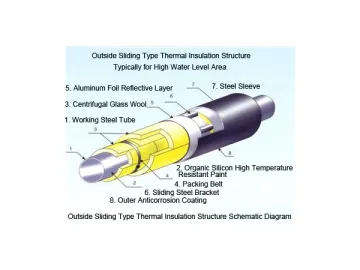

Specification of Outside Sliding Type Steel Jacketed Insulated Pipe

| Specification (mm) | Thermal Insulating Layer (mm) | Air Layer (mm) | Outer Protective Layer (mm) |

| DN108×4.5 | 110 | 18.5 | DN377×6 |

| DN133×4.5 | 110 | 30.5 | DN426×6 |

| DN159×5 | 110 | 17.5 | DN426×6 |

| DN219×6 | 120 | 29 | DN529×6 |

| DN273×7 | 130 | 42.5 | DN630×6 |

| DN325×7.5 | 130 | 16.5 | DN720×6 |

| DN377×8 | 150 | 14.5 | DN820×6 |

| DN426×8 | 150 | 39 | DN920×9 |

| DN529×10 | 170 | 16.5 | DN920×9 |

| DN630×10 | 170 | 15 | DN920×10 |

| DN720×10 | 180 | 10 | DN1120×10 |

| DN820×10 | 180 | 10 | DN1220×10 |

Composition

Our directly buried steel jacketed insulated pipe comprises the following parts.

1. Anticorrosive coating

This coating protects the outer steel tube from corrosion to prolong its working life.

2. Outer protective steel tube

It provides protection for the thermal insulation layer from erosion of groundwater, supports the working steel pipe, and bears certain external load to guarantee that the working steel pipe can work normally.

3. Polyurethane foam layer

It can ensure the temperature of the transported medium and that the surface of the outer protective steel tube keeps normal temperature.

4. Barrier and reflective layer

The barrier prevents the organic foam material entering the inorganic rigid high temperature resistant layer, and the reflective layer reflects partial heat of the high temperature resistant layer.

5. Inorganic rigid thermal insulation layer

It can resist high temperature, keep the interface temperature with the organic thermal insulating layer, and ensure the polyurethane foam does not be carbonized.

6. Drag reduction layer

Its function is to make sure that the working steel pipe can move freely during thermal expansion and contraction.

7. Working steel pipe

It ensures the normal flow of the medium to be transported.

Related Names

Steel Casing Pipe | Steel-in-Steel Pipe | Steam Pipe Insulation

Links:https://globefindpro.com/products/84911.html

-

Coal Tar Epoxy Coated Steel Pipe

Coal Tar Epoxy Coated Steel Pipe

-

Flange

Flange

-

Pipe Bends

Pipe Bends

-

19.5 Inch Aluminum Alloy Wheel

19.5 Inch Aluminum Alloy Wheel

-

LSAW Steel Pipe (Longitudinal Submerged Arc Welding)

LSAW Steel Pipe (Longitudinal Submerged Arc Welding)

-

19.5 Inch Steel Wheel

19.5 Inch Steel Wheel

-

Pipe Tee

Pipe Tee

-

HS38 Radial Ply Tire

HS38 Radial Ply Tire

-

3 Layer PE Coated Steel Pipe

3 Layer PE Coated Steel Pipe

-

Prefabricated Insulated Pipe for Underground Installation

Prefabricated Insulated Pipe for Underground Installation

-

API 5L Steel Pipe

API 5L Steel Pipe

-

17.5 Inch Steel Wheel

17.5 Inch Steel Wheel