Diesel Water Pump Set

Our diesel water pump set is a group of series product, which is developed by our company to meet the market requirements. It mainly depends on the elastic connecting shaft and the diesel engine to drive the pump set to work.

Merits

This diesel water pump set possesses such advantages as rational structure, high efficiency, superior cavitation performance, small vibration, low noise, stable operation, convenient disassembling, and some others.

Applications

The diesel water pump set is applicable for such industries as fire extinguishing system, waterworks, building water supply, irrigation, drainage pumping station, power station, industrial water supply system, shipping industry, mine drainage, petroleum, chemicals, and metallurgy, among others.

Is Series Pump

The IS series pump pertains to the single-stage, single-suction cantilever type centrifugal pump. It is used to pump the clear water or non-corrosive liquids. The shaft seal can be classified as soft stuffing type and mechanical sealing type. It is basically made from grey cast iron and carbon steel. Responding to customer needs, the pump with stainless steel shaft and copper impeller can be supplied.

Precautions for Use

The diesel water pump set is required to undertake a running test, for the purpose of better grasping both the operating performance of electromechanical equipment and the coordination of joint operations. Its main content includes the no-load test, automatic start-stop test, water filling test, as well as the load test.

Please regularly check the temperature of motor bearing and water pump when in use. The lubricating oil is required to be added. The bearing must be timely checked and handled, if an abnormal sound occurs. The foundation bolt of the diesel water pump set should be fixed tightly, if it is found to be loose. If the phenomenon of water leakage occurs, the gland packing should be disposed in time. The water circulation must be guaranteed to be normal, and the sealing performance of the pipeline should be tested. The water and gas sealing performance of all valves should be often kept in serviceable condition.

The following maintenance work should be done, when the diesel water pump set and pipeline are not used.

1. The residual water inside both water pump and pipeline must be drained.

2. Both water pump and pipeline can be cleaned, if they are convenient to be disassembled.

3. Please check whether a crack or hole is discovered in the impeller, or whether the fixed nut of the impeller is loose or not. The damaged part should be repaired or replaced. Repair or replacement will be needed, if the clearance of the anti-friction ring of the impeller exceeds a specified value.

4. If the water pump and pipeline are not disassembled, they should be sealed with the cover plate to guard against impurities.

Detailed Parameters

| Water Pump Model | Discharge Head (m) | Flow Capacity (m3/h) | Output (kW) | Engine Model | Speed (rpm) |

| IS100-65-315 | 23-30 | 26-60 | 7.5-11 | 495D | 1500 |

| IS125-100-250 | 12-20 | 48-120 | 7.5-11 | 495D | 1500 |

| IS125-100-315 | 19-33 | 48-120 | 11-15 | 495D | 1500 |

| IS150-125-400 | 29-53 | 96-224 | 30-45 | 4105D | 1500 |

| IS150-125-315 | 18-34 | 96-240 | 15-30 | 4100ZD | 1500 |

| IS200-150-250 | 22 | 400 | 37 | 4105D | 1500 |

| IS200-150-315 | 32 | 400 | 55 | 4105ZD | 1500 |

| IS200-150-400 | 50 | 400 | 90 | 6105AZLD | 1500 |

Related Names

Agriculture Power Generator | China Large Power Unit | Irrigation Pump Generating Device

Links:https://globefindpro.com/products/85115.html

-

Hydraulic Cylinder

Hydraulic Cylinder

-

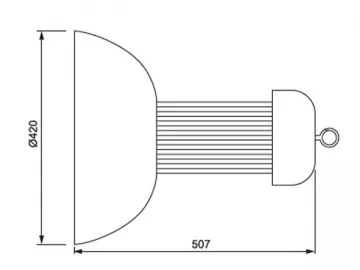

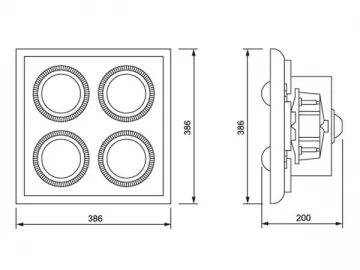

Integrated LED High Bay Light with Lampshade

Integrated LED High Bay Light with Lampshade

-

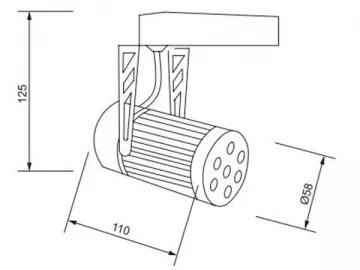

High Efficiency LED Track Light

High Efficiency LED Track Light

-

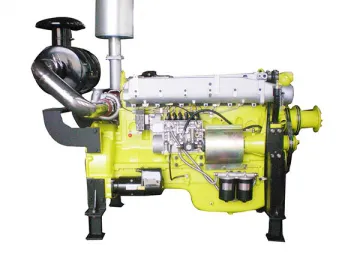

Generator Set Diesel Engine

Generator Set Diesel Engine

-

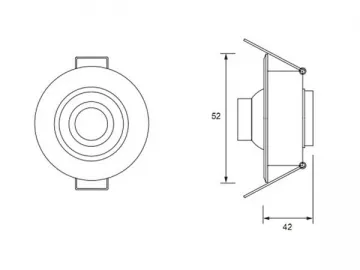

3W LED Ceiling Light

3W LED Ceiling Light

-

1W LED Ceiling Light

1W LED Ceiling Light

-

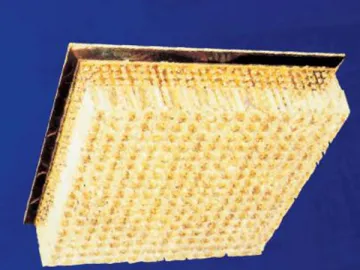

Integrated LED High Bay Light without Lampshade

Integrated LED High Bay Light without Lampshade

-

Square Base LED Crystal Ceiling Light

Square Base LED Crystal Ceiling Light

-

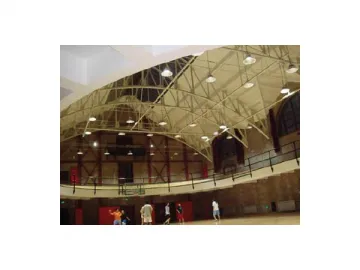

Aluminum LED High Bay Light

Aluminum LED High Bay Light

-

LED Explosion Proof Light with Die-Casting Aluminum Housing

LED Explosion Proof Light with Die-Casting Aluminum Housing

-

Tower Shape LED Crystal Ceiling Light

Tower Shape LED Crystal Ceiling Light

-

Double Head LED Grille Light

Double Head LED Grille Light