Hydraulic Cylinder

Reliable and professional production lines are fundamental to hydraulic cylinder quality. Successively acquired world class equipment from Japan and Germany, we have established an international level production line for high pressure hydraulic cylinders.

We also pay the highest attention to details. For proven quality, we implement a standard production flow for our liner hydraulic motors, during which workers are assigned to work for a specific production step so as to avoid defectives. Meanwhile, we carry out rigorous quality control from initial steps such as raw material acquisition. The complete quality assurance system effectively guarantees the product quality and reliability. Additionally, each of our delivering hydraulic cylinders undergoes strict life test, and the product performance is scientifically analyzed, so as to ensure the great compatibility with heavy machines.

We can produce various types of high pressure hydraulic cylinders for excavators and bulldozers. Models compatible with Komatsu, Hitachi, Kato, Sumitomo, Kobelco, Volvo, Caterpillar, Daewoo / Doosan, Hyundai, and more brands are all available.

Features

1. Small size, light weight, high strength

Our bulldozer hydraulic cylinders and excavator hydraulic cylinders are characterized by practical strength and fatigue resistance design, carefully-selected cylinder barrel and piston rod materials, as well as advanced processing and welding technologies. They are finally detected by ultrasonic flaw detection method to ensure overall reliability.

2. Sealing system

To meet the application demands in civil construction industry, this selection of bulldozer and excavator parts is fitted with NOK and Busak Shamban seals. This, coupled with the unique sealing system especially designed by our engineers, efficiently rejects sand and dust particles and reduces oil leakage as well. Thus, optimized piston seal performance is attained.

3. Cylinder barrel

Especially designed with optimized strength and dimensions, the cylinder barrel is also processed by barrel finishing technique to get smooth inner surface. This ensures surface hardness and improves wearing resistance as well.

4. Piston rod

The piston rod for the hydraulic cylinder firstly undergoes high frequency induction heating, and then is nickel or hard chrome plated, so as to improve its resistance to corrosion, wearing, and scratching. For high degree of finish and uniform surface texture, CNC barrel finishing machine is adopted to create superior rod surface quality, thus offering good piston seal performance and extended product lifespan.

5. Safety protection and buffering functions

Upon request, our range of hydraulic cylinder can be outfitted with specialized valves to achieve various additional functions. Also, the product is built with a buffering mechanism at the end of stroke to minimize the impact force.

Available Hydraulic Cylinder Models

| Komatsu | ||||

| PC220-7 | PC220-6 | PC200-3 | PC200-5 | PC200-6 |

| PC200-7 | PC120-6 | PC120-5 | PC120 | PC60-7 |

| PC60-6 | PC60-5 | PC360-7 | PC220-8 | PC300-7 |

| Caterpillar | ||||

| E330 | E330B | E330C | E330D | E200B |

| E320 | E320B | E320C | E320D | CAT312C |

| E312B | E312 | |||

| Hitachi | ||||

| EX300-3 | EX300-5 | EX220-5 | EX200-5 | EX200-3 |

| EX200-2 | EX2OO-1 | EX200-6 | EX200-5LC | EX230 |

| ZAX330 | ZAX240 | ZAX230 | ZAX200 | ZAX200-1 |

| ZAX200-3 | ZAX200-1LC | ZAX120 | ZAX330-3 | ZAX240-3 |

| ZAX200-3 | ZAX120 | ZAX200-1LC | UH07-7 | |

| Kobelco | ||||

| SK230-6 E | SK200-5 | SK200-3 | SK250-8 | SK200-6 |

| SK200-6E | SK200-8 | |||

| Hyundai | ||||

| R300-5 | R200-5 | R210-5 | R210-3 | R220-5 |

| R225-7 | R130-5 | R215-7 | ||

| Kato | ||||

| HD900-7 | HD900-5 | HD800-5 | HD800-7 | HD820-1 |

| HD820-3 | HD700- 2 | HD700- 5 | HD700- 7 | HD880-2 |

| Sumitomo | ||||

| SH200A 1 | SH200A 2 | SH200A 3 | SH280 | |

| Daewoo | ||||

| DH300-5 | DH280-3 | DH220-3 | DH220-5 | DH225-7 |

| DH150-7 | ||||

| Volvo | ||||

| EC210 | EC240 | |||

Production Workshops

Links:https://globefindpro.com/products/85116.html

-

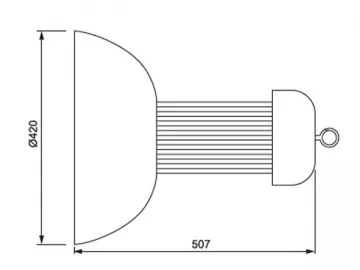

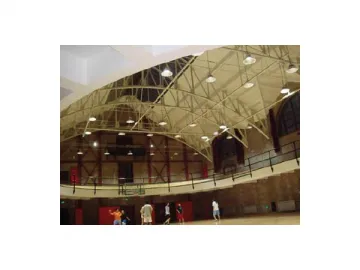

Integrated LED High Bay Light with Lampshade

Integrated LED High Bay Light with Lampshade

-

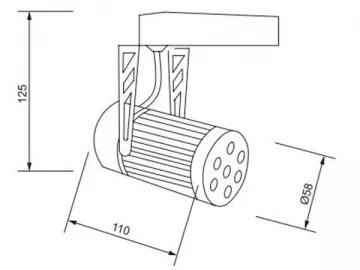

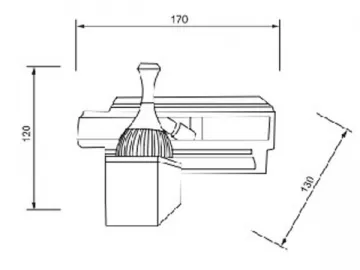

High Efficiency LED Track Light

High Efficiency LED Track Light

-

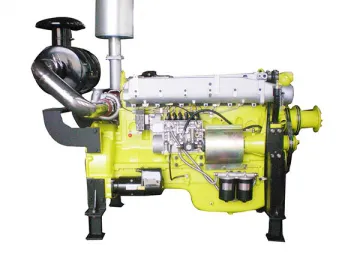

Generator Set Diesel Engine

Generator Set Diesel Engine

-

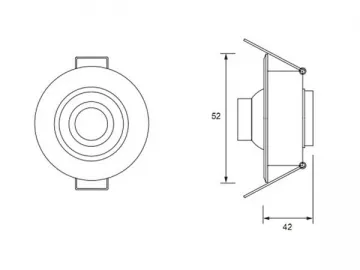

3W LED Ceiling Light

3W LED Ceiling Light

-

1W LED Ceiling Light

1W LED Ceiling Light

-

One Head LED Mirror Light

One Head LED Mirror Light

-

Diesel Water Pump Set

Diesel Water Pump Set

-

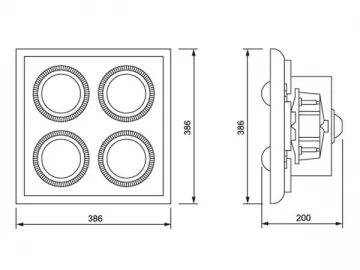

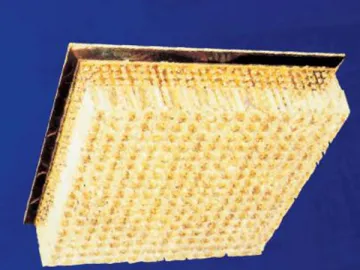

Integrated LED High Bay Light without Lampshade

Integrated LED High Bay Light without Lampshade

-

Square Base LED Crystal Ceiling Light

Square Base LED Crystal Ceiling Light

-

Aluminum LED High Bay Light

Aluminum LED High Bay Light

-

LED Explosion Proof Light with Die-Casting Aluminum Housing

LED Explosion Proof Light with Die-Casting Aluminum Housing

-

Tower Shape LED Crystal Ceiling Light

Tower Shape LED Crystal Ceiling Light