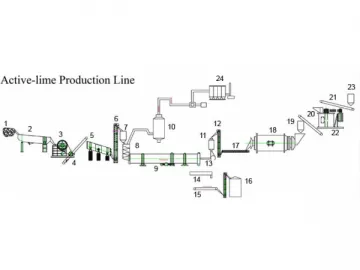

Active-lime Plant/Quicklime Plant

On the active-lime plant/quicklime plant, dolomite or limestone is sent through crushing, screening, pre-heating, calcination and cooling processes. The resulting products have consist good quality and low burnt-over rate, and thus can be used in building material, paper making, and metallurgy industries.

General Introduction

1. A cement rotary kiln is primarily used for producing cement clinker. There are two types of kilns available currently, wet process kiln and dry process kiln.

2. A metallurgical kiln is mainly used for magnetic roasting of lean iron ore as well as oxidation roasting of chrome ore and nickel ore in steel plants.

In refractory plant, this employed to roast various refractories of high alumina content.

In aluminum factory, the kiln is designed to roast clinker and aluminum hydroxide.

3. A lime kiln is available for producing quicklime through the calcination of limestone.

Process Flow

Application

The active-lime plant/quicklime plant is most commonly utilized to calcine high-grade cement in the cement plant, though sometimes it is also employed to produce catalytic agent, molecular sieve, and zinc oxide. The number of uses for this processing line is nearly endless across the steel annealing, nonferrous smelting, metallurgy, chemical, and building material industries.

Features

1. Modern advancements in the calcining technology allow our rotary kiln to have features, such as the wheel catch, plunger metering pump, speed control valve, and graphite seal for the contact block.

2. An industrial computer is used to enable high automation. It visualizes the calclining process with a fluorescent screen. An infrared scanner is utilized for transmitting information on the calcining conditions to the computer.

3. Production efficiency grows 10% with this active-lime production line. Improved processing efficiency also brings 5% to 10% production increase, and cuts heat consumption by 15%.

Specifications

| Type | Specifications (m) | Inclination (%) | Capacity (t/h) | Rotation Speed (r/min) | Motor Power (kw) | Weight (t) | Remarks |

| Rotary Kiln | 1.4×33 | 3 | 0.9-1.3 | 0.39-3.96 | 18.5 | 47.5 | |

| 1.6×36 | 4 | 1.2-1.9 | 0.26-2.63 | 22 | 52 | ||

| 1.8×45 | 4 | 1.9-2.4 | 0.16-1.62 | 30 | 78.2 | ||

| 1.9×39 | 4 | 1.65-3 | 0.29-2.93 | 30 | 77.59 | ||

| 2.0×40 | 3 | 2.5-4 | 0.23-2.26 | 37 | 119.1 | ||

| 2.2×45 | 3.5 | 3.4-5.4 | 0.21-2.44 | 45 | 128.3 | ||

| 2.5×40 | 3.5 | 9.0-10.5 | 0.44-2.44 | 55 | 149.61 | ||

| 2.5×50 | 3 | 6.25-7.4 | 0.62-1.86 | 55 | 187.37 | ||

| 2.5×54 | 3.5 | 6.9-8.5 | 0.48-1.45 | 55 | 196.29 | ||

| 2.7×42 | 3.5 | 10.0-11.0 | 0.10-1.52 | 55 | 198.5 | ||

| 2.8×44 | 3.5 | 12.5-13.5 | 0.437-2.18 | 55 | 201.58 | ||

| 3.0×45 | 3.5 | 12.8-14.5 | 0.5-2.47 | 75 | 210.94 | ||

| 3.0×48 | 3.5 | 25.6-29.3 | 0.6-3.48 | 100 | 237 | ||

| 3.0×60 | 3.5 | 12.3-14.1 | 0.3-2 | 100 | 310 | ||

| 3.2×50 | 4 | 40.5-42 | 0.6-3 | 125 | 278 | ||

| 3.5×145 | 3.5 | 25 | 0.46-1.38 | 2×75 | 830.38 | ||

| 3.5×54 | 4 | 58-65 | 0.39-3.54 | 220 | 360 |

Related Names

China Lime Kiln | Limestone Production Equipment | Clinker Rotary Kiln

Links:https://globefindpro.com/products/85416.html

-

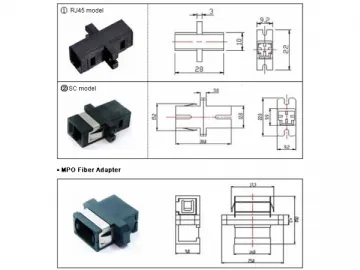

SC/LC/FC/ST/MU/D4/DIN Fiber Optic Adapter

SC/LC/FC/ST/MU/D4/DIN Fiber Optic Adapter

-

Pulse Jet Dust Collector

Pulse Jet Dust Collector

-

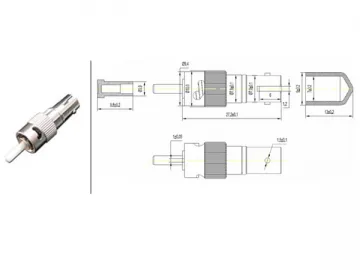

SC/LC/FC/ST/MU/D4/DIN Fiber Optic Patch Cord

SC/LC/FC/ST/MU/D4/DIN Fiber Optic Patch Cord

-

Optical Time Domain Reflectometer

Optical Time Domain Reflectometer

-

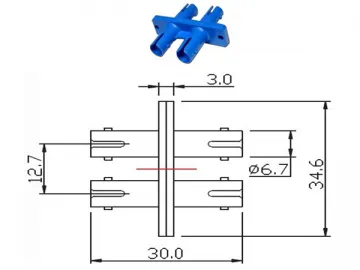

MT-RJ/MPO Fiber Optic Adapter

MT-RJ/MPO Fiber Optic Adapter

-

Mineral Processing Line

Mineral Processing Line

-

Cement Production Line

Cement Production Line

-

Plug-in Type Fixed Attenuator

Plug-in Type Fixed Attenuator

-

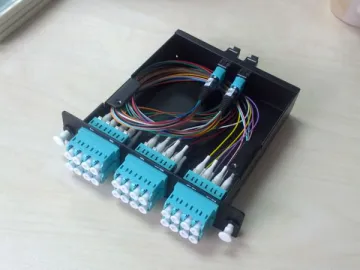

MPO Fiber Optic Cassette

MPO Fiber Optic Cassette

-

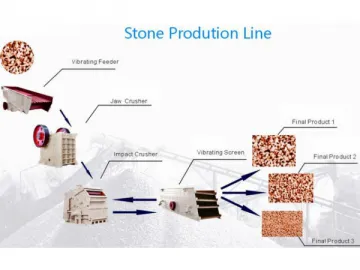

Sand and Gravel Production Line

Sand and Gravel Production Line

-

Screw Classifier

Screw Classifier

-

Fixed Type Optical Distribution Frame

Fixed Type Optical Distribution Frame