1250-type Steel Coil Slitting Line

| Slitting Machine | Decoiler | Tension-Free Coiling Machine for Edge Scrap | Coiling Machine |

Features

1. Our 1250-type steel coil slitting line is provided with elegant appearance and rational process layout. Its maximum speed is 200m/min, and the width tolerance is ±0.05mm. The thickness of burrs is one thirtieth of that of the plate. Furthermore, the maximum quantity of the slit strips is 30, and the minimum width of the slit strips reaches 15mm.

2. As a configuration of our product, the double knife holder is accompanied with the on-line production and off-line knife positioning system. This greatly saves the time for positioning knives. Moreover, the powerful automation capability allows the operating time to be significantly reduced.

3. This 1250-type steel coil slitting line adopts the seamless winding technology. Its tension control system makes use of the wool felt. Also, it can be equipped with either RB21 series or BB series belt tensioner imported from Japan.

4. The on-line type edge scrap machine can be equipped for coiling the trimmed edge of over 2mm. Its speed is synchronous with the speed of the slitting machine. Alternatively, the off-line type tension-free coiling machine can be added for coiling the trimmed edge of less than 2mm.

5. Furthermore, the human-machine interface gives wonderful performance.

a. Through the touch screen, the user is allowed to accomplish such operations as the fault alarm, fault diagnosis, operating conditions, as well as the setting, modifying and commissioning of technical parameters.

b. When the equipment breaks down, the touch screen will display both historical alarm information and real-time alarm information. Then, the system will activate the warning indicator at the top right corner of the touch screen. Meanwhile, the sound-light warning light is forced to work. In this way, our equipment can be operated smoothly.

6. The another highlight is strong automation capability.

Our 1250-type steel coil slitting line offers such functions as the automatic loading of coiled materials, the self-acting strip threading, the automatic processing of both loop strip and tailing, the self-driven positioning of oblique mouth, the fixed-length cutting, fixed-weight cutting, the automatic centering of the center of the decoiler, and the automatic regulation of the tension of the edge scrap machine. In addition, the height of the coil lifter can be adjusted on basis of the change of the coil diameter.

7. The high-precision processing equipment and high-quality purchased components can offer the top-ranking machining, assembly and painting techniques. Then, our 1250-type steel coil slitting line is provided with low failure rate and ultra high stability. Both time and cost for maintenance can be also reduced.

Applications

1. In use of 1250-type steel coil slitting line, the metal plates with the thickness from 0.3mm to 4.0mm can be precisely cut. The maximum width of the plate to be slit is 1300mm, and the maximum weight of the coil reaches 17 tons.

2. Our product is applicable for processing and cutting the cold-rolled sheets, electrolytic galvanized sheets, hot-dip galvanized sheets, color-coated sheets, stainless steel sheets, aluminum sheets, copper sheets, and some others.

3. With high efficiency, this type machine can bring about considerable benefits. It is proper for those customers who have high annual output of machined plates with the width from 200mm to 1300mm.

4. Our company has cooperated with Taiwan Chunyuan Company, and produced one set of 1250-type steel coil slitting line. This line is dedicated for processing electrical steel, and it has gone into operation without a hitch. Its quality and stability are highly appreciated by our clients.

Technical Parameters

| Raw Materials | Materials | Cold-rolled sheets, electrolytic galvanized sheets, hot-dip galvanized sheets, pre-painted steel sheets, stainless steel sheets, aluminum sheets, copper sheets, etc |

| Max. Weight of Coil | 17 tons | |

| Width of Steel Coil | 200~1300mm | |

| Thickness of Steel Coil | 0.3~4.0mm | |

| Internal Diameter of Steel Coil | φ508/610mm | |

| External Diameter of Steel Coil | φ800mm~1800mm | |

| Processing Capability | 3.0 mm wide | 7pcs |

| 2.0 mm wide | 15pcs | |

| 1.2mm wide | 30pcs | |

| Machine Capacity | Max. Speed | 150m/min (Customizable, Maximum Speed: 200m/min) |

| Threading Speed | 15m/min | |

| Width Tolerance | ±0.05mm | |

| Burr | ≤1/30 thickness of plate (in relation to cutter gap and cutter point) | |

| Snake Shape | 1.0mm/2m | |

| Edge Misalignment of Coil | ≤0.5mm | |

| Coil Cone | ≤2.0mm | |

| Automated Capacity | Automatic Feeding | 1. Automatic centering of both height and width 2. Automatic regulation of the center of the decoiler 3. Precise calculation, high safety and reliability, and easy operation |

| Automatic Strip Threading | 1. The width of plate can be automatically calculated. 2. The side guide system can be automatically positioned. 3. The No.1 loop is automatically formed. 4. Convenient operation, as well as high safety and reliability | |

| Fixed-Length Automatic Processing | 1. The cutting length is calculated automatically. 2. The system can automatically match the preset length with the cutting length. 3. It is safe and reliable. | |

| Automatic Adjustment of the Center of the Uncoiler | It is used during the automatic feeding process. | |

| Coordinated Operation of Production Line | During the automatic cutting process in the production line, the speed is matched, and the uncoiler gives stable tension. In addition, no newly increased defect can be found on the surface of the plate, and the working efficiency is high. | |

| Automatic Selection of Stacker | The system can automatically select the stacker in accordance with the number of sheets. | |

| Automatic Knife Change | When configured with double knife holder, the system can offer this function. | |

| The coil separator is lifted automatically and slowly. | The coil separator is lifted automatically and slowly as the diameter of coil is changed. | |

| The trim scrap machine can automatically adjust tension. | During the automatic production process, the coiling tension of the edge scrap machine is automatically adjusted according to the degree of tightness of the edge scrap. |

Furthermore, this 1250-type steel coil slitting line can be customized as per client requirements.

Process Flow Diagram of 1250-type Steel Coil Slitting LineRelated Names

Aluminum Slitting Machine | Sheet Metal Processing Equipment | Coated Steel Coil Slitter

Links:https://globefindpro.com/products/85870.html

-

PVC Electrical Tape

PVC Electrical Tape

-

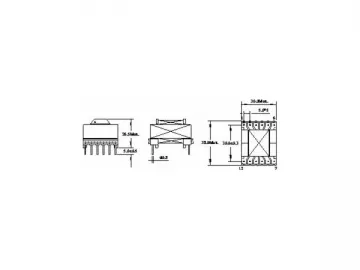

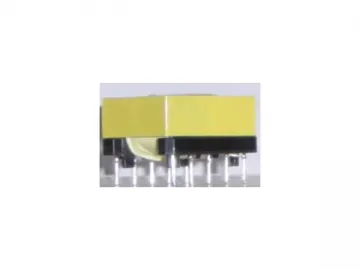

ER Series Switch Mode Power Transformer

ER Series Switch Mode Power Transformer

-

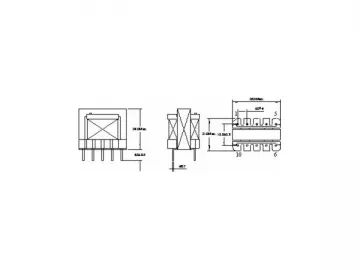

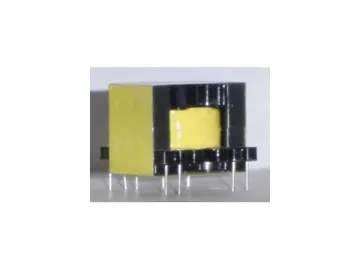

EFD Series Ballast Choke

EFD Series Ballast Choke

-

EI Series Ballast Choke

EI Series Ballast Choke

-

PQ Series Switch Mode Power Transformer

PQ Series Switch Mode Power Transformer

-

PE Coated Aluminum Coil (Polyester Coating)

PE Coated Aluminum Coil (Polyester Coating)

-

1850-type Steel Coil Rotary Shear Line

1850-type Steel Coil Rotary Shear Line

-

1250-type Steel Coil Rotary Shear Line

1250-type Steel Coil Rotary Shear Line

-

800-type Steel Coil Rotary Shear Line

800-type Steel Coil Rotary Shear Line

-

Mirror Finish Aluminum Composite Panel

Mirror Finish Aluminum Composite Panel

-

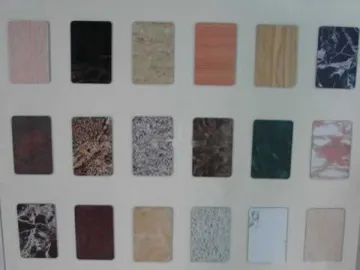

Stone Grain and Wood Grain Aluminum Composite Panel

Stone Grain and Wood Grain Aluminum Composite Panel

-

1650-type Steel Coil Slitting Line

1650-type Steel Coil Slitting Line