1850-type Steel Coil Rotary Shear Line

| Flying Shear | Straightener | Uncoiling Machine | Stacker |

Structure and Features

1. Appearance and Quality

Our 1850-type steel coil rotary shear line is characterized by high-rigidity structure, beautiful appearance, and rational layout. Thanks to the big-league processing, assembly and painting techniques, the equipment features pretty high durability, low failure rate, as well as the significant reduction of time and cost for maintenance.

The high-rigidity leveler comes with the 6-roller system, which consists of 17 work rolls, 19 intermediate rolls and 210 back-up rolls. This enables the plate to achieve a 10-fold improvement. Also, the high-strength plate is allowed to be leveled.

The shearing machine can be custom-made with double-crankshaft structure. Moreover, the flying shear system is imported with original packaging from Japan. Due to the high dynamic stability performance, the high-precision synchronization of the shearing machine and strips can be guaranteed, and the faultless high-precision cutting process can be also realized.

2. High-Efficiency Operation

This 1850-type steel coil rotary shear line offers the maximum shear frequency of up to 160pcs/min and the maximum feeding speed of 80m/min. Under condition of uniform velocity, the length tolerance of the plate reaches ±0.2mm. The diagonal tolerance reaches ±0.5mm, and the thickness of burrs is one thirtieth of that of the plate. Additionally, the stacking fault is lower than 1mm, and the evenness of the plate achieves a 10-fold improvement.

There are totally two sets of stackers for interchangeable operation. The multi-station packaging system is used to greatly improve the working performance. Moreover, the double station for coil preparation is able to raise the lifting efficiency of the crane.

3. Outstanding Human-Machine Interface

The industrial display and two sets of superior-quality cameras are equipped for real-time detection of the stacking process. Additionally, the touch screen is utilized to complete such operations as the fault alarm, operating conditions, fault diagnosis, as well as the setting, modifying and commissioning of the technical parameters.

Furthermore, the 1850-type steel coil rotary shear line is designed with the impeccable warning system. Once the equipment failure occurs, both historical alarm information and real-time alarm information can be seen on the touch screen, and the system will activate the warning indicator at the top right corner of the touch screen. Simultaneously, the sound-light warning light will begin to work so as to further guarantee the smooth operation of our equipment.

4. Powerful Automation Capability

a. In use of our 1850-type steel coil rotary shear line, the self-driven loading of coiled materials can be realized.

b. The position of the shaft of decoiler in the production line is adjusted automatically.

c. Both tension and position of the plate are tested, and the automatic beating operation can be achieved to make plates orderly.

d. The stacking height is detected in real time, and the height of the lift can be automatically adjusted.

e. The real-time detection of the cutting tension of the knife allows the self-acting shutdown and the changeover of the stacking rack to come true.

f. The cutting length can be matched for use.

g. At last, the stacking capability can be monitored in real time.

Applications

1. As a cross cutting line, the 1850-type steel coil rotary shear line is commonly used for the high-precision cutting of diversified metal plates with the thickness from 0.2mm to 3.2mm, the maximum strip width of 1850mm, and the maximum coil weight of 30 tons. It can process and cut the aluminum sheets, copper sheets, cold-rolled sheets, color-coated sheets, stainless steel sheets, electrolytic galvanized sheets, hot-dip galvanized sheets, and much more.

2. This 1850-type steel coil rotary shear line is suitable for those clients who own high yearly output of machined plates with the width from 500mm to 1850mm. In prevention of wasting resources, the 1650-type or other smaller-sized shear line is generally used for processing the materials with the width of less than 400mm.

3. Our company has cooperated with Shandong Xiaochuang Sheet Metal Processing Co., Ltd. for the production of this product, which has been successfully put into production. The product quality and stability are highly appreciated by our clientele.

Technical Specifications

| Raw Materials | Materials | Aluminum sheets, copper sheets, cold-rolled sheets, pre-painted steel sheets, stainless steel sheets, electrolytic galvanized sheets, hot-dip galvanized sheets, and more |

| Weight of Coil | 30 tons | |

| Width of Steel Coil | 500~1850mm | |

| Thickness of Steel Coil | 0.5~3.2mm | |

| Internal Diameter of Steel Coil | φ508/610mm | |

| External Diameter of Steel Coil | φ800mm~2100mm | |

| End-Product Specifications | Length of End Product | Minimum: 300mm Maximum: 5000mm (customizable) |

| Length of the First Stacker | 3000mm or customized | |

| Length of the First Stacker | 5000mm or customized | |

| Equipment Capacity | Max. Speed | 80m/min |

| Threading Speed | 15m/min | |

| Length Tolerance | ±0.3mm (constant speed) | |

| Diagonal Tolerance | ±0.5mm/2m | |

| Burr | ≤1/25 thickness of plate | |

| Deviation between Stacking Layers | ≤1mm | |

| Evenness | Less than one-fifth of the condition of the raw material | |

| Plate Appearance | 10-fold improvement | |

| Plate Surface | No visible defect | |

| Automated Capacity | Automatic Adjustment of the Center of the Uncoiler | The position of the decoiler shaft can be automatically adjusted in the production line. |

| Automatic Beating Function | 1. Both tension and position of the plate can be examined. 2. The automatic beating operation can be realized to make plates orderly. | |

| Automatic Stacking Function | 1. Real-time detection of stacking height 2. The height of the lift can be automatically regulated. | |

| Fixed-Tension Cutting Function | 1. Real-time detection of the cutting tension of the cutter 2. The auto stop function can be realized. 3. The material storage rack can be changed. | |

| Automatic Cutting Function | The shearing length can be optimized for use. | |

| Camera Function | Real-time monitoring and stacking capabilities | |

| Automatic Feeding Function | The automatic loading of coiled materials can be realized. |

This 1850-type steel coil rotary shear line can be customized as per client requirements.

Process Flow Diagram of 1850-type Steel Coil Rotary Shear LineRelated Names

Color Coated Sheet Cutter | Steel Processing Line | Sheet Metal Machinery

Links:https://globefindpro.com/products/85869.html

-

1250-type Steel Coil Slitting Line

1250-type Steel Coil Slitting Line

-

PVC Electrical Tape

PVC Electrical Tape

-

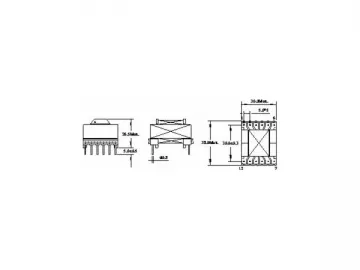

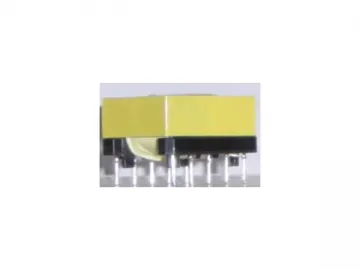

ER Series Switch Mode Power Transformer

ER Series Switch Mode Power Transformer

-

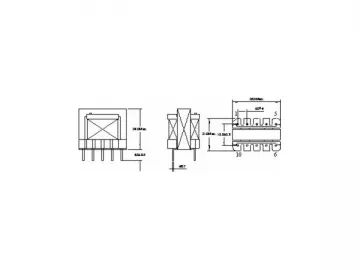

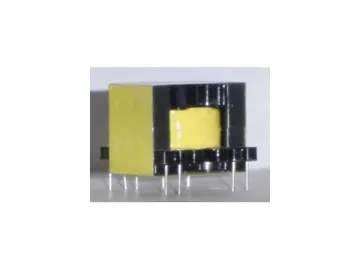

EFD Series Ballast Choke

EFD Series Ballast Choke

-

EI Series Ballast Choke

EI Series Ballast Choke

-

PQ Series Switch Mode Power Transformer

PQ Series Switch Mode Power Transformer

-

1250-type Steel Coil Rotary Shear Line

1250-type Steel Coil Rotary Shear Line

-

800-type Steel Coil Rotary Shear Line

800-type Steel Coil Rotary Shear Line

-

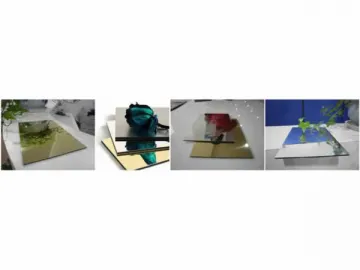

Mirror Finish Aluminum Composite Panel

Mirror Finish Aluminum Composite Panel

-

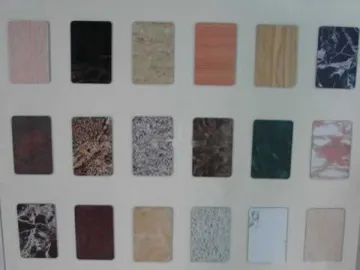

Stone Grain and Wood Grain Aluminum Composite Panel

Stone Grain and Wood Grain Aluminum Composite Panel

-

1650-type Steel Coil Slitting Line

1650-type Steel Coil Slitting Line

-

1650-type Steel Coil Rotary Shear Line

1650-type Steel Coil Rotary Shear Line