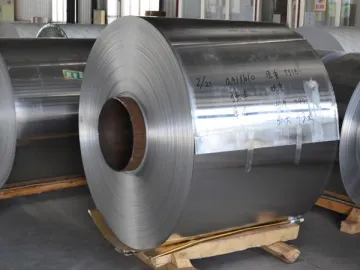

1050 Mill Finish Aluminum Coil

The 1050 mill finish aluminum coil, with an aluminum content of ≥ 99.5%, is currently one of the most commonly used industrial aluminum series. It has the general characteristics of aluminum material, such as small density, good electrical and thermal conductivity, as well as excellent corrosion resistance. With high plasticity and good machinability, the aluminum coil can be processed into aluminum sheets, aluminum strips, aluminum foils and aluminum extrusions.

Because of aluminum 1050, this selection of mill finish aluminum coil supports gas welding, arc welding, spot welding, and contact welding. Its strength can be improved by cold deformation, and the only available form of heat treatment is annealing. The recrystallization temperature, related to the content of impurities and the degree of deformation, is generally at about 200 ℃.

The aluminum coil is often used in the production of daily necessities, lighting fixtures, reflective panels, decorations, chemical containers, heat sinks, signboards, electronics, nameplates, stampings and other products. It also can be applied to some occasions with high requirements on corrosion resistance and formability, but with not strict requirements on strength. For example, chemical equipment is its typical application.

Links:https://globefindpro.com/products/85913.html

-

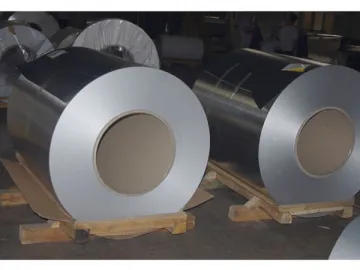

1100 Mill Finish Aluminum Coil

1100 Mill Finish Aluminum Coil

-

Stone Coated Metal Roof Tiles (Roof Shingle)

Stone Coated Metal Roof Tiles (Roof Shingle)

-

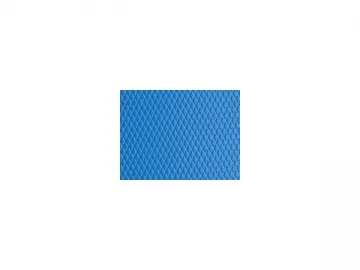

Diamond Embossed Aluminum Coil

Diamond Embossed Aluminum Coil

-

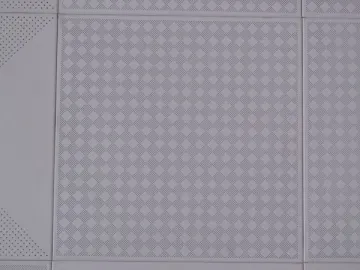

Stucco Embossed Aluminum Coil

Stucco Embossed Aluminum Coil

-

Single Side PE Coated Aluminum Coil

Single Side PE Coated Aluminum Coil

-

FDM720 Wheel Loader

FDM720 Wheel Loader

-

FDM890 Forklift Truck

FDM890 Forklift Truck

-

FDM756T-18 Telehandler

FDM756T-18 Telehandler

-

FDM8120 Forklift Truck

FDM8120 Forklift Truck

-

Aluminum Ceiling Tiles

Aluminum Ceiling Tiles

-

PVDF Coated Aluminum Coil

PVDF Coated Aluminum Coil

-

Stone Coated Metal Roof Tiles (Rainbow Tile)

Stone Coated Metal Roof Tiles (Rainbow Tile)