PVDF Coated Aluminum Coil

The PVDF coating for aluminum coil refers to a vinylidene fluoride homopolymer or a copolymer coating including vinylidene fluoride and a small amount of a fluorine-containing vinyl monomer. Its stability and solidity in chemical structure makes its physical properties different from the general coating.

In addition to the excellent mechanical properties like wear resistance and impact resistance, the PVDF coated aluminum coil also shows lasting fade resistance and UV resistance especially in the harsh climate and environment.

After being baked into film under high temperature, the coating achieves tight molecular structure, thus providing the aluminum coil with superior weather resistance. Therefore, this selection of color coated aluminum coil is especially suitable for indoor and outdoor decoration in public places, as well as decoration and display in commercial chains, exhibition advertising, etc. It is your best choice if you are looking for painted aluminum sheets, aluminum building material, aluminum decoration material, etc.

Parameters of the PVDF Coated Aluminum Coil

| PVDF | |

| Items | Technical requirements |

| Thickness of coating film | ≥26μm |

| Gloss deviation | Gloss< 70, limit error≤10% Gloss≥70, limit error≤5% |

| Pencil hardness | ≥3H |

| Adhesion | No less than Grade 1 |

| Flexibility | ≤2T |

| Boiling water resistance | 2h, no color change |

| Color difference | ΔE≤2.0 |

| MEK | ≥150times |

| Specification: | |

| Aluminum thickness | 0.18-1.00mm |

| Aluminum width | 800-1600mm |

Links:https://globefindpro.com/products/85904.html

-

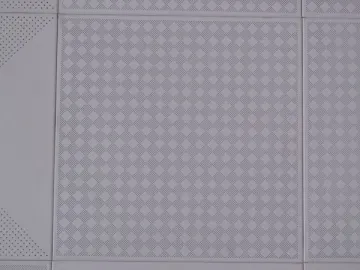

Aluminum Ceiling Tiles

Aluminum Ceiling Tiles

-

FDM8120 Forklift Truck

FDM8120 Forklift Truck

-

FDM756T-18 Telehandler

FDM756T-18 Telehandler

-

FDM890 Forklift Truck

FDM890 Forklift Truck

-

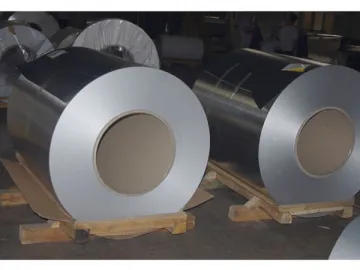

1050 Mill Finish Aluminum Coil

1050 Mill Finish Aluminum Coil

-

1100 Mill Finish Aluminum Coil

1100 Mill Finish Aluminum Coil

-

Stone Coated Metal Roof Tiles (Rainbow Tile)

Stone Coated Metal Roof Tiles (Rainbow Tile)

-

3003 Mill Finish Aluminum Coil

3003 Mill Finish Aluminum Coil

-

FDM880 Forklift Truck

FDM880 Forklift Truck

-

Stone Coated Metal Roof Tiles (Classic Tile)

Stone Coated Metal Roof Tiles (Classic Tile)

-

8011 Mill Finish Aluminum Coil

8011 Mill Finish Aluminum Coil

-

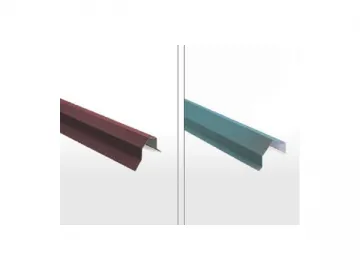

Roofing Accessories

Roofing Accessories