FDM766T-28 Telehandler

On the basis of our many years' experience in heavy equipment such as the wheel loader, forklift truck and excavator, we develop the FDM766T-28 telehandler on our own by carving out the innovative idea, absorbing the leading-edge technology concerning material handling devices at home and abroad, as well as exploiting the computer aided design and finite element analysis methods. This range of telehandler is often used in quarries, mining industry and construction sites to serve as stone lifting equipment.

Performance Parameter and Dimensions

28 Ton Telehandler, Model FDM766T-28

| Self weight | 30000kg | Lifting time | 8.5s | |

| Rated load lifting capacity | 28000kg | Total cycling time | 18s | |

| Max. lifting load | 30000kg | Hydraulic torque converter | Single stage, four elements | |

| Traveling speed | 0-29km/h | Fuel tank capacity | 200L | |

| Turning angle | 30° | Hydraulic oil tank capacity | 350L | |

| Wheelbase | 4200±15mm | Engine | Model | Steyr WD615.58G of Hangzhou Engine |

| Max. grade ability | ≥21° | Rated power | 175kW | |

| Overall dimension (L×W×H) | 9680*3120*3685(mm) | Tires type | 4×26.5-25-32PR | |

| Self weight | 30000kg | Lifting time | 8.4s | |

| Rated load lifting capacity | 28000kg | Total cycling time | 15s | |

| Max. lifting load | 32000kg | Hydraulic torque converter | Single stage, four elements | |

| Traveling speed | 0-29km/h | Fuel tank capacity | 200L | |

| Turning angle | 30° | Hydraulic oil tank capacity | 350L | |

| Wheelbase | 4140mm | Engine | Model | Steyr WD615.58G of Hangzhou Engine |

| Max. grade ability | ≥ 20° | Rated power | 175kW | |

| Overall dimension (L×W×H) | 9680×3120×3650 mm | Tires type | 4×26.5-25-32PR | |

The telehandler integrates the advanced structure and technology of the forklift truck and wheel loader together. Its fork loading and lifting system is the eight-bar linkage lifting structure composed of two-seat beam suitable for heavy load working, new enhanced boom arm structure with overall frame structure as well as the horizontal boom arm hydraulic cylinder. Compared with the general mast lifting mechanism of the forklift truck, the telehandler is available with increased front overhang making the stone loading and unloading more convenient.

The drive axle of the telescopic handler adopts the four-wheel drive mechanism rather than the rear wheel drive mechanism of the forklift truck to raise the off-road performance of the product. The frame of the telehandler is the box type. Through 3D modeling, we simulate the actual working conditions to carry out the stress analysis for making sure that all the mechanical parts have enough strength to avoid the damage of the unbalanced loading and impact to the frame structural parts during the working process.

The hydraulic system of the telehandler adopts the dual pump confluence and shunt structure consisting of coaxial flow amplifying steering gear, priority valve and unloading valve to form the priority steering system. On the oil return line, the hydraulic oil cooler is brought into use for decreasing the system hydraulic oil temperature to keep system reliability, reduce the operating force, enhance the working efficiency as well as save the energy and lower the consumption.

The telehandler cab is designed by conforming to the ergonomic principles. The driver's operational and control parameters are optimized. Due to the adoption of the new flexible suspension and sealing technologies, the vibration and noise are reduced with the enhancement of the comfort.

In general, the telehandler has novel structure, nice appearance, high working efficiency, low fuel consumption, excellent off-road performance, outstanding working flexibility and reliability, high performance price ratio, etc. Apart from loading and unloading the rough stone block in mine, harbor and wharf, it can also be applied for material loading and unloading in plate processing plant, building construction, road construction, tunnel engineering, etc. After changing the fork into other working devices such as bucket and wood clamping device, the telescopic material handler can also achieve loading, unloading and carrying the whole package or the large and long material. It is a kind of material handling machine with high efficiency and wide application range.

Links:https://globefindpro.com/products/85946.html

-

Bright Annealing Line(For Stainless Steel)

Bright Annealing Line(For Stainless Steel)

-

Tension Leveler

Tension Leveler

-

Electrolytic Tinning Line (for Strip Steel)

Electrolytic Tinning Line (for Strip Steel)

-

Hot Dip Galvanizing Line and Galvalume Line (for Strip Steel)

Hot Dip Galvanizing Line and Galvalume Line (for Strip Steel)

-

FDM720T Wheel Loader

FDM720T Wheel Loader

-

Cleaning Unit

Cleaning Unit

-

Color Coating Line (for Strip Steel)

Color Coating Line (for Strip Steel)

-

Welding Machine

Welding Machine

-

Continuous Pickling Line(for Strip Steel)

Continuous Pickling Line(for Strip Steel)

-

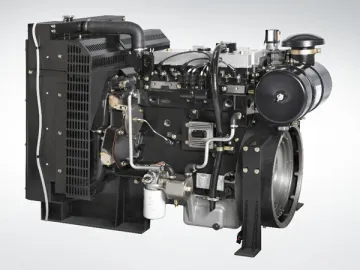

Genset Engine

Genset Engine

-

Annealing and Pickling Line (For Stainless Steel)

Annealing and Pickling Line (For Stainless Steel)

-

Bell Annealing Furnace

Bell Annealing Furnace