Continuous Pickling Line(for Strip Steel)

The continuous pickling line is where the strip steel coil is pre-treated before being cold rolled. Its main function is to rid the steel surface of any tough deposits of oxides. Main processes taking place on this strip processing line are pickling, water cleaning, drying, and trimming.

Process Flow of the Continuous Pickling Line

Coil Transfer Car—Pay-Off Reel—Movable Guard—7-Roll Tension Leveler with Pinch Rolls—Vertical-Type Strip-Centering Device--—Crop Shear with Pinch Roll—Corner Cutter with Scrap Discharge Basket—Vertical Type Strip-Centering Device—Backwashing Tank—Pickling Bath—Washing Bath—Hot Air Blowpipe—Vertical Type Strip-Centering Device—Pinch Roll—Exit Loop-Storage Pit (with pivotable arc-shaped roller table)—Vertical Type Strip Centering Roll—Pinch Roll—Circle Shear—Trim Winder—3-Roll Bridle Roll—Oiler—Dual-Function Deflector Pinch Roll—Movable Guard—Rewinder—Coil Transfer Car

As a coil processing line specialist in China, we can also produce other styles of metal surface treatment equipment in addition to continuous pickling lines. Included are continuous annealing line, bright annealing line, etc. We welcome you to contact us if you are looking for automated lines for steel processing.

Links:https://globefindpro.com/products/85943.html

-

Welding Machine

Welding Machine

-

Color Coating Line (for Strip Steel)

Color Coating Line (for Strip Steel)

-

FDM766T-28 Telehandler

FDM766T-28 Telehandler

-

Bright Annealing Line(For Stainless Steel)

Bright Annealing Line(For Stainless Steel)

-

Tension Leveler

Tension Leveler

-

Electrolytic Tinning Line (for Strip Steel)

Electrolytic Tinning Line (for Strip Steel)

-

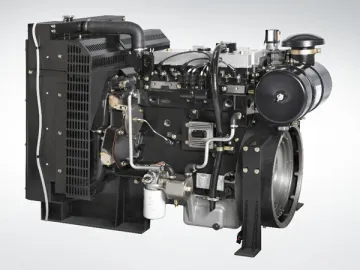

Genset Engine

Genset Engine

-

Annealing and Pickling Line (For Stainless Steel)

Annealing and Pickling Line (For Stainless Steel)

-

Bell Annealing Furnace

Bell Annealing Furnace

-

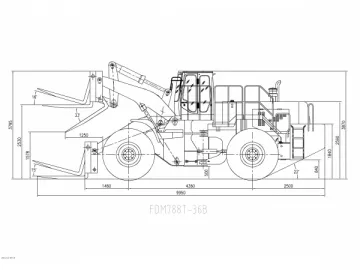

FDM788T-36B Telescopic Handler

FDM788T-36B Telescopic Handler

-

FDM8200 Forklift Truck

FDM8200 Forklift Truck

-

Steel Storage Unit

Steel Storage Unit