Steel Storage Unit

The steel storage unit is an indispensable item in our coil processing line to ensure there is always enough stock of steel coil available for continuous production. According to different circumstances on the production line, this coil processing equipment can be made into floor-standing type or horizontal version. If placed near the pay-off reel, the steel storage unit is called entry storage section. If paced near the recoiler or re-winder, the unit is called exit storage section.

Typical use of entry storage section is storing enough steel strips beforehand. When the pay-off reel on the production line stops to change steel coil, the storage section is all on hand to supply the coil to ensure an uninterrupted production. The exit storage section is to gather up the surplus strip steel that the recoiler can not accommodate. When the coil is removed from the recoiler, the steel storage unit will send the strip steel to the recoiler for winding.

There is a carriage, also known as coil transfer car, in the entry storage unit. The carriage slides along the track from left to right within the steel storage unit. During this process, the steel strip between the carriage and deflector roll is raised by the support bracket of the slack loop to reduce the length of steel strip that hangs down on the loop. Hence, the tension of slack loop becomes tighter than before.

The exit storage section utilizes a winch for pull-in and let-out of the steel strip. The motion of the winch is powered by a speed reducer which is connected to a variable frequency motor. The speed reducer has only one output shaft that drives the drum of the winch. Meanwhile, the drum winds in or out the wire rope, which is attached to the coil transfer car in the exit storage section. In this way, the car will be drawn near or away from the winch. Somewhere around the track, there are limit switches to control the farthest position the transfer car can move to. An encoder is fitted to the tail of variable frequency motor to measure the speed of steel wire rope. Speed warning signals are sent by the electrical control.

Features

Via the guide rail and limit switch roller, the coil transfer car can run smoothly and stably within the steel storage unit.

Adjustment of Support Bracket on the Slack Loop

The coil transfer car moves from left to right within the storage section. Its wheels enable the support bracket to turn 90 degrees, via a mechanism known as the cam follower. During this motion, the steel ball of the follower is stuck in the grooves of the cam so that the support bracket will be stationary. If the bracket keeps moving, then users need to tighten the nut of the compression spring until the bracket stop moving. If the bracket stops moving before the steel ball arrives at the groove of the cam, then loosen the nut on the compression spring.

This steel storage unit can measure the number of steel strips. It is storage speed and strip sending speed can also be set properly according to the requirements.

Related Names

Steel Decoiler | Heavy Duty Metal Feeder | Steel Production Equipment

Links:https://globefindpro.com/products/85937.html

-

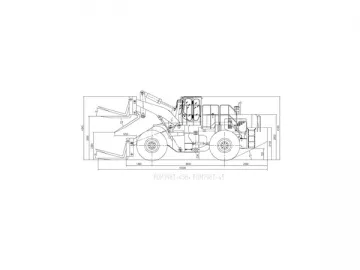

FDM8200 Forklift Truck

FDM8200 Forklift Truck

-

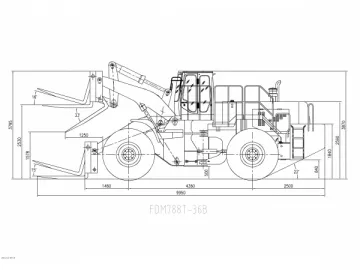

FDM788T-36B Telescopic Handler

FDM788T-36B Telescopic Handler

-

Bell Annealing Furnace

Bell Annealing Furnace

-

Annealing and Pickling Line (For Stainless Steel)

Annealing and Pickling Line (For Stainless Steel)

-

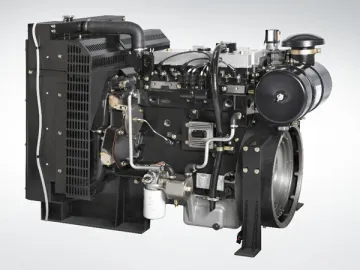

Genset Engine

Genset Engine

-

Continuous Pickling Line(for Strip Steel)

Continuous Pickling Line(for Strip Steel)

-

Annealing Furnace

Annealing Furnace

-

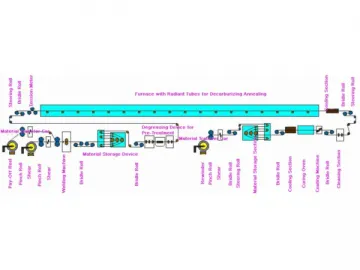

Continuous Annealing Line (For Strip Steel)

Continuous Annealing Line (For Strip Steel)

-

LOVOL® Generator Set Engine

LOVOL® Generator Set Engine

-

Continuous Annealing Line (for Silicon Steel)

Continuous Annealing Line (for Silicon Steel)

-

根据该客户OA修改意见,该产品删除

根据该客户OA修改意见,该产品删除

-

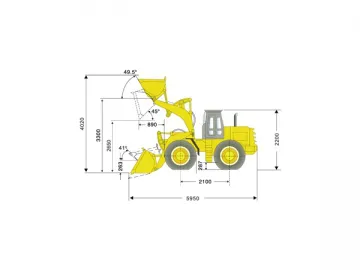

FDM 778T-32 Telehandler

FDM 778T-32 Telehandler