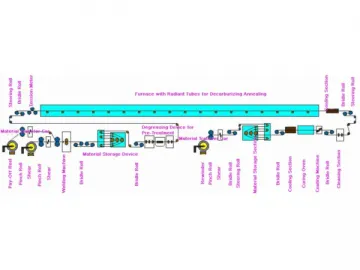

Continuous Annealing Line (For Strip Steel)

The continuous annealing line for strip steel processing combines several separate operations, including cleaning, bell annealing, cooling, flattening, and finishing, into a single process. This strip processing line utilizes a floor-standing continuous annealing furnace to replace the previous bell annealing furnace that can only operate intermittently. This ensures higher productivity. Strip steel that has been worked on this continuous annealing line is uniform in softness and ductility. Ductility is important in shaping a more refined workpiece.

One technical challenge facing every continuous annealing line manufacture is that annealing often results in oxidization of metal surface, resulting in scale. To address this issue, a sealing device is installed at the entry to the furnace chamber. This sealing device has already been patented, namely the sealing device for silicon steel and ordinary carbon steel continuous furnace door. Thanks to the seal, the sealing performance of the furnace door is greatly enhanced. Durable and long-lasting, the seal does not need to be replaced for many years. This saves on production and operating cost.

Process Flow of the Continuous Annealing Line for Strip Steel

Coil Transfer Car→Pay-Off Reel→Pinch Roll→Cutter Welder→Pinch Roll→Slack Loop→Washing Machine→Drying Machine→Bridle Roll→Steering Roll→Tension Measuring Roll→Annealing Furnace→Cooling Section 1→Age Hardening Section→Cooling Section 2→Bridle Roll→Exit Slack Loop→Steering Roll→Bridle Roll→Shear→Pinch Roll→Cantilever Type Recoiler→Coil Transfer Car

As an expert in coil processing equipment, we also supply continuous annealing lines especially for processing of silicon steel strips. Browse our product catalogue for details please.

Links:https://globefindpro.com/products/85935.html

-

Annealing Furnace

Annealing Furnace

-

Steel Storage Unit

Steel Storage Unit

-

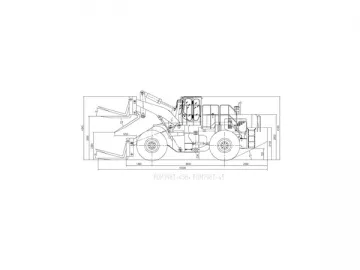

FDM8200 Forklift Truck

FDM8200 Forklift Truck

-

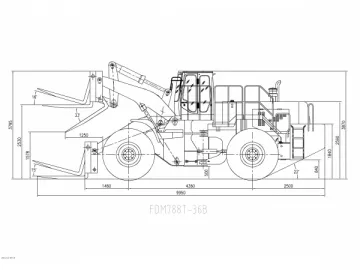

FDM788T-36B Telescopic Handler

FDM788T-36B Telescopic Handler

-

Bell Annealing Furnace

Bell Annealing Furnace

-

Annealing and Pickling Line (For Stainless Steel)

Annealing and Pickling Line (For Stainless Steel)

-

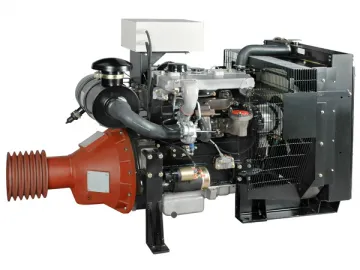

LOVOL® Generator Set Engine

LOVOL® Generator Set Engine

-

Continuous Annealing Line (for Silicon Steel)

Continuous Annealing Line (for Silicon Steel)

-

根据该客户OA修改意见,该产品删除

根据该客户OA修改意见,该产品删除

-

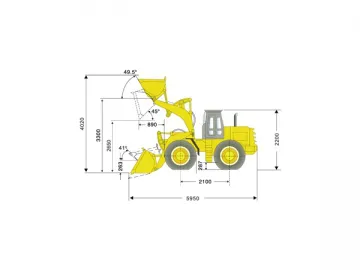

FDM 778T-32 Telehandler

FDM 778T-32 Telehandler

-

LOVOL® Pump Engine

LOVOL® Pump Engine

-

FOTON® Pump Engine

FOTON® Pump Engine