Continuous Annealing Line (for Silicon Steel)

General Introduction

This continuous annealing line is a new style of strip processing line developed by our design team. Most of our technicians have been working in the continuous galvanizing line industry for more than 8 years. They have gained high-level skills and a wealth of experience that can be transferred to the design and manufacture of the continuous annealing line for silicon steel.

The continuous annealing furnace and all other steel processing machinery for composing the continuous annealing line are made by our own technicians. Our technical specialists are also responsible for on-site installation and operator training. Hence customers can rely on our product quality and integrated after-sales service.

How and Why Continuous Annealing

Along the continuous annealing line, the cold-rolled silicon steel stock is firstly degreased to rid the steel surface of any oil stains. Then, in a protective atmosphere, the steel stock undergoes processes known as decarburization and recrystallization in annealing furnaces to obtain the desired grain size, reduce iron loss and improve magnetic properties. Finally, a layer of insulation is applied to the surface of strip steel for improved insulation performance. The layer also makes the steel more workable.

Main Application Areas

One use of our continuous annealing line is to heat-treat cold-rolled silicon steel strip. Silicon steel is an iron alloy that has from 3% to 5% silicon. It is an indispensable item in the electric power, electronics, or military industry. Usually stacked together to form a core, the silicon steel strip can be used in electric motor, generator, and transformer.

The manufacturing and heat treatment process of cold-rolled silicon steel strips is rather complicated. The manufacturing and heat treatment techniques often have strict standards to meet. In foreign countries, those processing techniques are usually protected by the patent. Enterprise may face survival challenges if they lose the ownership of the silicon steel strip manufacturing technique.

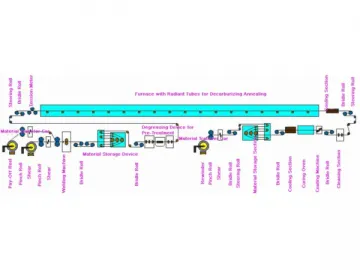

Process Flow of the Continuous Annealing Line

Coil Transfer Car → Pay-Off Reel → Pinch Roll → Shear → Welding Machine →Bridle Roll → Material Storage Device → Steering Roll → Bridle Roll → Cleaning Unit (including roller brush, cleaning system, chemical degreasing, electrolytic greasing, squeegee roll)→ Hot Air Blowpipe → Steering Roll → Bridle Roll →Tension Meter → Continuous Annealing Furnace → Cold Air Blow Pipe → Bridle Roll → Steering Roll → Deflector Roll → Cleaning Section → Hot Air Blowpipe → Coating Machine → Curing Oven → Cold Air Blowpipe → Material Storage Device → Steering Roll →Bridle Roll → Shear → Pinch Roll → Rewinder → Material Transfer Car

Major Coil Processing Equipment for Composing the Continuous Annealing Line

| As one of the necessary unit for composing our coil processing lines, the cleaning unit is mainly used to scour any oil and grime from the surface of strip steel and prepare it for the subsequent annealing and galvanizing process. | |

| The continuous annealing furnace is a commonly used style of heat treatment furnace responsible for electrical steel annealing. It serves a purpose of eliminating the internal strain in the cold-rolled steel via a process known as re-crystallization. |

Links:https://globefindpro.com/products/85933.html